Selected Early Engines

R.A.F., Rapp, Rausenberger, Renard, Renault, R.E.P., Rheinische, Roberts, Rolls-Royce

Compiled by Kimble D. McCutcheon

Published 20 Feb 2023; Revised 13 Apr 2023

Renault

Louis Renault, along with his brothers Marcel and Fernand, founded Société Anonyme des Moteurs Renault at Billancourt, France on 24 Dec 1898. In 1907, Renault began building aircraft engines, many of which led the way for French industry and formed the basis for many designs in other countries.

Inlines and Vees

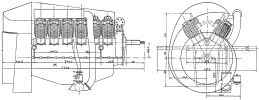

One of the first Renalut aircraft engines was a water-cooled inline four with a 110 mm (4.331") bore, 160 mm (6.299") stroke and 6.082 l (371.15 in³) displacement. It was rated 38.5 hp at 1,100 rpm and weighed 129.7 kg (286 lb).

A water-cooled inline four designed for dirigible use had a 116 mm (4.567") bore, 150 mm (5.906") stroke and 6.341 l (386.95 in³) displacement. It was rated 42.5 hp at 1,300 rpm and weighed 400 kg (880 lb).

A water-cooled 90° V-8 had a 100 mm (3.937") bore, 120 mm (4.724") stroke and displaced 7.540 l (460.11 in³). It developed 58.5 hp at 1,200 rpm and it weighed 260 kg (574 lb).

The V4, a 90° V-4 with a 90 mm (3.543") bore, 120 mm (4.724") stroke and 3.054 l (186.34 in³) displacement was rated at 25 ‑ 30 hp and weighed 109.7 kg ( 242 lb).

An air-cooled 90° V-8, designed for use in dirigibles, had a 90 mm (3.543") bore, 140 mm (5.512") stroke and 7.125 l (434.80 in³) displacement. It was rated 50.5 hp at 1,500 rpm and weighed 249.5 kg (550 lb).

|

|

|

| 50/60 hp (Wiki) | (Wiki) | 50/60 hp (Wiki) |

The 50/60 hp was one of the most popular early Renault air-cooled V-8s, producing 50 hp at 1,800 rpm. First run in 1908, his engine won several honors, including the 1910 Michelin Cup, a non-stop flight of nearly eight hours covering a total distance of 370 miles, and the 1910 Michelin Grand Prize, which covered 225 miles in 4 hours and 54 minutes. The engine's bore was 90 mm (3.543"), its stroke 120 mm (4.724"), and its displacement 6.107 l (372.6 in³). The propeller was driven from the camshaft at one-half engine speed. The weight was 169.2 kg (373 lb), the length 1,232 mm (48.5"), the width 673 mm (26.5"), and the height 648 mm (25.5").

Renault used similar construction for several air-cooled models. The cylinders and heads were cast from iron with integral cooling fins. The cylinder head joints used copper-asbestos washers, and a clamp pressing against the cylinder heads secured the heads and cylinders to the crankcase via four long studs. Tractor engines used a cowl to gather cooling air; pusher engines had a fan was mounted on the crankshaft opposite the propeller end that forced air into baffles partially surrounding the cylinders. The valves were vertically opposed in a pocket at the combustion chamber side. The inlet valve was directly operated by a tappet from the camshaft in the Vee and seated in a cage that also formed the inlet pipe elbow. The exhaust valve was operated by a push rod and rocker arm. It seated in the cylinder head and could be serviced after the inlet valve cage was removed. The steel pistons were fitted with three cast-iron rings. The connecting rods had H-section shanks and ran side-by-side on the crankpins. Ball bearings were used on the crankshaft ends and plain bearings on the intermediate mains. A gear pump supplied pressure lubrication and magnetos furnished ignition.

|

|

|

| Renault 70 hp (NARA) | 80 hp (NARA) | |

The 1907 WB, a 70 hp air-cooled 90° V-8 had a 96 mm (3.780") bore, 120 mm (4.724") stroke, 6.949 l (424.05 in³) displacement and weighed 179.6 kg (396 lb). Fuel and oil consumptions were 0.64 and 0.045 lb/hp/hr. The engine was 1,156 mm (45.5") long, 757 mm (29.8") wide, and 833 mm (32.8") high. The WC was a WB with an external oil pump.

An 80 hp air-cooled 90° V-8 had a 100 mm (3.937") bore, 120 mm (4.724") stroke, 7.540 l (460.11 in³) displacement and weighed 201.8 kg (445 lb).

|

|

|

|

|

| Renault WS (NASM) | ||||

The WS was 1908 geared air-cooled 90° V-8 with a 105 mm (4.134") bore, 130 mm (5.1182") stroke, 9.005 l (549.52 in³) displacement and 4.0:1 compression ratio. It developed 88 hp at 1,800 rpm and weighed 210.01 kg (463 lb). Fuel and oil consumptions were 0.772 and 0.066 lb/hp/hr. This engine used articulated connecting rods, resulting in cylinder banks that were directly opposite one another. The propeller was driven by the camshaft, resulting in a 2.0:1 reduction gear ratio.

|

| Renault 130 hp (Wiki) |

The 130-hp, an air-cooled 90° V-12 using WS cylinders displaced 13.508 l (824.31 in³) and had a 4.0:1 compression ratio. It was rated 130 hp but developed 138 hp at 1,800 rpm. Fuel and oil consumptions were 0.76 and 0.066 lb/hp/hr. It weighed 350.2 kg (772 lb). It also employed articulated connecting rods and 2:1 gear reduction. Developed from the 100 hp V-12, it featured a 90° bank included angle instead of the previous 60°. The 130-hp followed construction practices used in the WS, including using the same cylinders, heads and valve gear. A fan driven from the crankshaft rear blew air into a sheet metal plenum between the two cylinder rows. The lower crankcase was an oil reservoir from which a gear pump driven by a vertical shaft via helical gears on the camshaft provided pressure lubrication. The five-main-bearing crankshaft had two outer ball thrust bearings. A Zenith 42 DC dual carburetor on each crankcase side fed each cylinder bank. Two magnetos mounted transversely atop the camshaft provided dual ignition. Bosch Z.U.6, S.E.V. C.6 and Lavallette magnetos were used. [Wiki]

|

|

|

|

|

| (NARA) | (Wiki) | (Wiki) | (Wiki) | (Wiki) |

The 90-hp model was an air-cooled 60° V-12 with a 90 mm (3.543") bore, 140 mm (5.512") stroke and 10.688 l (652.20 in³) displacement that weighed 289.4 kg (638 lb).

The 100-hp, a slightly larger geared 60° V-12 with a 96 mm (3.779") bore, 140 mm (5.512") stroke and 12.160 l (742.06 in³) displacement was rated 100 hp at 1,800 rpm. It weighed 289.85 kg (639 lb), was 1,430 mm (56.3") long, 818 mm (32.2") wide and 1,003 mm (39.5") high.

Early in WWI Renault built a water-cooled engine series based on cylinders with 125 mm (4.921") bores and 150 mm (5.906"") strokes. Steel cylinder pairs were encased in a welded sheet-steel water jacket. Inlet and exhaust valves were inclined in the cylinder head at 14° to the vertical axis and were operated by rocker arms from an overhead camshaft.

A direct-drive vertical displacing 11.045 l (673.99 in³) with a 4.25:1 compression ratio was rated 130 hp at 1,300 rpm and weighed 202.3 kg (446 lb). The crankshaft ran on four plain bearings and had H-section connecting rods. Two Bosch ZR-6 magnetos and a Zenith 18DF duplex carburetor were fitted. Cast iron pistons were used, and lubrication was by pressure and splash with gear pumps scavenging and delivering fresh oil.

|

|

|

|

|

|

| Renault 8Gd (Wiki) | Renault V-8s (NARA) | ||||

The 8G,a direct drive 50° V-8 displacing 14.726 l (898.65 in³) and with a 4.5:1 compression ratio delivered 198 hp at 1,550 rpm and weighed 215 kg (474 lb). The four-throw crankshaft was carried in three plain bearings, and articulated H-section connecting rods were used. The pistons were made from aluminum alloy. Cooling water was circulated by a centrifugal pump with a single impeller and two outlets. The engine was equipped with a Zenith duplex carburetor and four S.E.V. four-cylinder magnetos supplied dual ignition. Gear pumps delivered oil under pressure to the bearings, scavenged the sump, and supplied fresh oil to the system. Fuel and oil consumptions were 0.53 and 0.055 lb/hp/hr. Numerous 8G variants appeared with steadily increasing power outputs: 8G = 140 hp; 8Ga = 150 hp; 8Gb = 160 hp; 8Gc = 175 hp; 8Gd = 190 hp; 8Gdy = 200 hp; 8Ge = 200 hp.

A 50° V-12 displacing 22.089 l (1347.97 in³) with a 4.6:1 compression ratio delivered 285 hp at 1,550 rpm. Fuel and oil consumptions were 0.518 and 0.055 lb/hp/hr. The V-12 resembled the V-8 in many details, but the crankshaft ran in four main bearings and two centrifugal water pumps were used. Four S.E.V. six-cylinder magnetos supplied dual ignition. Weight was 379.2 kg (836 lb).

|

|

| Renault 12Fe (A39) | |

The 12Fe was a water-cooled 50° V-12 with a 125 mm (4.921") bore, 150 mm (5.906") stroke, 22.089 l (1,347.98 in³) displacement and 5.0:1 compression ratio. It weighed 360.2 kg (794 lb), was rated 300 hp but delivered 315 hp at 1,550 rpm and 327 hp at 1,600 rpm. The cylinders were made in pairs, the valves had 61 mm (2.402") clear diameters, 45° seats and 10 mm (0.394") lift. The inlets opened 6° late and closed 45° late; the exhausts opened 48.5° early and closed 19° late. The single-impeller water pump had double outlets.

Renault also built a vertical eight using four 12Fe cylinder pairs. It was rated 220 hp and employed spur propeller reduction gears.

A 47.5° V-12 built with individual built-up welded steel cylinders with a 125 mm (4.921") bore and 160 mm (6.299") stroke displaced 23.562 l (1,437.8 in³). The six-throw crankshaft was carried in four plain bearings. H-section articulated connecting rods and cast iron he pistons with three rings were used. Four six-cylinder magnetos supplied dual ignition.

Renault engines developed late in WWI featured a new type valve gear with four valves seated vertically in the cylinder head and a single overhead cam driven by a shaft and bevel gears. The two inlet valves were operated by a double rocker from one cam lobe and the two exhaust valves by single rocker arms from two cam lobes. An oil-tight housing encasing the camshaft and valve gear was bolted to the cylinder heads.

A geared water-cooled 60° V-12 tractor with a 150 mm (5.906") bore, 140 mm (5.512") stroke, 29.688 l (1,811.68 in³) displacement and 4.8:1 compression ratio was rated 258 hp at 2,100 rpm. The spur propeller reduction gear ran at a 3:2 ratio. The weight was (213.19 kg (470 lb), length 1,091 mm (42.95"), width 610 mm (24"), and height 869 mm (34.21"). Each built-up and welded steel cylinder pair was encased in a sheet-steel water jacket. The crankshaft was carried in four plain bearings and the articulated master and link rods had tubular shanks. The pistons were aluminum alloy. Twin Zenith QR duplex carburetors and two 12-cylinder S.E.V. magnetos were used. Gear pumps provided pressure lubrication and a centrifugal pump with two outlets circulated the cooling water.

A direct-drive 60° V-12 with 180 mm (7.087") bore and stroke, 5.0:1 compression ratio and displacing 54.965 l (3,598.28 in³) was rated 400 hp but developed 404 hp at 1,400 rpm and 468 hp at 1,700 rpm. It weighed 419.6 kg (925 lb). The individual steel cylinders had welded-on sheet steel water jackets. The crankshaft was supported in seven plain bearings, and the articulated connecting rods had tubular shanks. Two Zenith carburetors were placed on each engine side, and four magnetos were arranged in two tiers at the aft end. Gear-type oil pressure and scavenge pumps provided pressure lubrication.

|

|

|

| Renault 400 hp Cannon Engine (NARA, A39) |

||

A 3:2 geared 60° V-12 with a 130 mm (5.118") bore, 140 mm (5.513") stroke, 22.299 l (1,360.77 in³) displacement and 5.0:1 compression ratio was rated 400 hp at 2,100 rpm. Designed for tractor use only, the propeller shaft, driven by spur gears, was hollow to permit using a 37-mm cannon mounted in the Vee. It weighed 378.7 kg (835 lb). The steel cylinders with welded-on water jackets had two inlet and two exhaust valves placed vertically in the heads. Each had a 37 mm (1.457") clear diameter, a 10.2 mm (0.402") lift and 30° seats. Inlet valves opened 10° late and closed 50° late; exhaust valves opened 56° early and closed 10° late. The crankshaft was carried in seven plain hearings, and the articulated connecting rods were arranged so that the link rod would lead and trail at alternate crank throws. The pistons were made of aluminum alloy. Two duplex carburetors in the Vee supplied the cylinders in sets of three, and the oil pumps were gear type. Fuel and oil consumptions were 0.528 and 0.055 lb/hp/hr. Two twelve-cylinder S.E.V. magnetos furnished dual ignition. Renault also built a V-12 in this series fitted with planetary propeller reduction gears that was rated at 450 hp. Its magnetos were mounted on brackets integral with the lower crankcase half just below the crankshaft centerline at each engine side.

The 12J was a direct-drive water-cooled 60° V-12 with a 130 mm (5.118") bore, 180 mm (7.087") stroke 28.67 l (1,749.56 in³) displacement and 5.0:1 compression that delivered 425 hp at 1,500 rpm, 468 hp at 1,750 rpm and weighed 421.8 kg (930 lb).

|

| 12Kb (A39) |

The 12Kb was a direct-drive water-cooled 60° V-12 with a 134 mm (5.276") bore, 180 mm (7.087") stroke and 30.462 l (1,858.88 in³) displacement that was rated 450 hp at 1,600 rpm and weighed 437.7 kg (965 lb). It was 2,000 mm (78.74") long, 950 mm (37.4") wide and 1,250 mm (49.21") high.

|

| 12K, 1927 French Government Prize Winner (A39) |

An engine from the 12K series won a million Franc first prize in a 1925 French Government competition after a 5-hour bench test, 2-hour flight, and 30 8-hour runs, maintaining 420 hp at 1,500 rpm throughout the tests. A similar Renault engine with a 140 mm (5.512") bore, 33.251 l (2,029.08 in³) displacement and 2:1 spur-geared propeller drive won third prize. Individual forged steel cylinders surrounded with welded-on sheet-steel water jackets each had four inclined valves seating in the head. The valves were operated in pairs by means of fully-enclosed T-shaped rocker arms and overhead camshaft. The inlet valves opened 10° late and closed 50° late; exhaust valves opened 56° early and closed 10° late. The camshaft housings were mounted independent of the cylinders at three points: at the front on a housing acting as an oil return, at the center by a duralumin support between the cylinders that extended to the crankcase, and at the rear on an aluminum housing containing the camshaft drive shaft. The camshaft drive shafts were provided with universal joints at each end. These features reduced the time required to make adjustments after changing a cylinder. The crankshaft had seven plain bearings supported by duralumin caps attached to the upper crankcase half. The connecting rods had H-section shanks and were fitted with bronze-backed white-metal bearings. The aluminum alloy pistons had four compression rings above the piston-pin and one oil-scraper ring below it; the piston pin was fixed in the piston. The auxiliaries were arranged at the engine rear. Two magnetos furnishing dual ignition were driven from a common transverse shaft. The water pump was driven from a shaft below and parallel with the crankshaft. At a camshaft end was a distributor for a compressed-air starter, and a tachometer drive was fitted to the other camshaft end. Two gear-type scavenge pumps were located at each engine end, a pressure pump supplied the crankshaft and connecting rod bearings, and another pressure pump supplied the overhead camshafts. Oil from the scavenging pumps was delivered to a Renault centrifugal oil cleaner running at 6,000 rpm Air entered the four Zenith carburetors through the engine crankcase.

The 12Ke with its 5.3:1 compression ratio was rated 500 hp at 1,650 rpm. Fuel and oil consumptions were 0.50 and 0.03 lb/hp/hr. Weight was 495.3 kg (1,092 lb), length was 1,908 mm (75.1"), width was 1,052 mm (41.4") and height was 1,242 mm (48.9"). It was equipped with four Zenith carburetors and two S.E.V. magnetos.

The 12M was a direct-drive water-cooled 60° V-12 with a 150 mm (5.906") bore, 175 mm (6.890") stroke, 37.110 l (2,264.6 in³) displacement and 4.8:1 compression ratio that was rated 500 hp, but developed 550 hp at 1,500 rpm and 600 hp at 1,650 rpm. It weighed 529.8 kg (1,168 lb), was 1,805 mm (71.08") long, 780 mm (30.7") wide and 1,104 mm (43.45") high.

In 1926, Renault introduced the water-cooled 60° V-12 series consisting of six direct-drive and geared engines in three displacements, designated 12J, 12K and 12M. They used individual steel cylinder barrels with integral heads and welded-on valve ports that were encased by corrugated sheet-steel welded-in-place water jackets. Four valves seated vertically in the cylinder heads were operated by rocker arms and a single overhead camshaft supported in a housing attached to the cylinder heads. A separate rocker arm actuated each exhaust valve, and a forked rocker arm operated two inlet valves. The entire valve mechanism was enclosed by a sheet-metal cover. An auxiliary shaft, driven from the crankshaft rear by a dog clutch, drove a vertical shaft through bevel gears. This drove inclined shafts through another bevel gear. The camshafts were driven by bevel gears from drive shafts that engaged with the inclined shafts by means of splined joints. The vertical shaft above the centerline drove a centrifugal oil cleaner. The vertical shaft below the centerline drove the water and oil pumps, and a transverse shaft drove two A.M. fuel pumps. The magnetos were driven by a transverse shaft located above the crank centerline, this shaft being driven from a spiral gear on the auxiliary shaft that engaged in the crankshaft end. The crankshaft was supported in seven plain bearings held between the upper and lower sections of an aluminum alloy crankcase joined along the horizontal centerline. A deep-groove ball bearing carried the propeller thrust load in either direction. The crankpins and journals were of large diameter and the disk-shaped crank webs enhanced torsional rigidity. Helical grooves prevented oil leakage from the bearing ends and jets were fitted to carry oil into the hollow crankpins from where it was led to the crankpin bearings. Articulated connecting rods with H-section shanks were machined all over. The link rod was hinged upon a large knuckle pin between master rod supporting flanges. The master rod big end cap used three bolts to capture a white-metal-lined phosphor-bronze bushing. The aluminum alloy pistons had flat heads with reinforcing and cooling ribs underneath. Five rings were fitted above and one below the hollow full-floating piston pin with end locating plugs.

|

|

| 12Ja (A39) | 12Jb (A39) |

The 12Ja direct-drive version was a water-cooled 60° V-12 with a 125 mm (4.921") bore, 170 mm (6.693") stroke, 25.035 l (1,527.70 in³)displacement and 5.6:1 compression ratio rated 450 hp at 1,800 rpm and 505 hp at 2000 rpm. Fuel and oil consumptions were 0.484 and 0.022 lb/hp/hr. Weight was 369.2 kg (814 lb), length was 1,628 mm (64.09"), width was 953 mm (37.51"), and height was 1,066 mm (41.96"). Two Zenith 55D.J. duplex carburetors furnished the mixture.

The 12Jb geared version had either a 3:2 or 2:1 spur-gear reduction ratio. The normal rating was 500 hp at 2,020 rpm, and the maximum was 542 hp at 2,240 rpm. Weighing 404.2 kg (891 lb), it was 1,645 mm (64.85") long.

The 12Jc was an improved direct-drive 12Ja with a 5.8:1 compression ratio normally rated 500 hp at 2,100 rpm but delivering 560 hp at 2,130 rpm.

|

|

|

|

|

| 12Kg (A39) | 12Kh (A39) | |||

The 12Kg was a direct-drive 60° V-12 with a 134 mm (5.276") bore, 180 mm (7.0879") stroke, 30.462 l (1,858.88 in³) displacement and 5.6:1compression ratio normally rated 550 hp at 1,800 rpm, but capable of 620 hp at 2,000 rpm. Dry weight was 474 kg (1,045 lb), length 1,821 mm (71.68"), width 1,050 mm (41.33") and height 1,137 mm (44.76"). Four Zenith 60J carburetors furnished the mixture. Fuel and oil consumptions were 0.484 and 0.022 lb/hp/hr.

The 12Kh was similar to the 12Kg except for the 1.7668:1 spur type propeller reduction gears. Normal rated output was 570 hp at 7,900 rpm and maximum was 633 hp at 2,100 rpm. Dry weight was 529 kg (1,166 lb) and overall length was 1,840 mm (72.46").

The 12Ki was a 12Kh with a 6.0:1 compression ratio. Weight was 548.80 kg (1,210 lb) and its normal output was 580 hp at 2,050 rpm and 640 hp at 2,243 rpm.

The 12Mc was a direct-drive 60° V-12 with a 160 mm (6.299") bore, 180 mm (7.087") stroke, 43.429 l (2,833.29 in³) displacement and 5.3:1 compression ratio whose normal output was 750 hp at 1,800 rpm and maximum output was 830 hp at 2,000 rpm. Fuel and oil consumptions were 0.484 and 0.033 lb/hp/hr, and weight was 608.7 kg (1,342 lb). Four Zenith 75 Ki carburetors furnished the mixture.

The 12Md was a geared 12Mc that was rated normally 750 hp at 1,900 rpm and delivered 850 hp at 2.100 rpm. Dry weight was 608.7 kg (1,452 lb).

During 1933, Renault was developing a geared water-cooled V-12 capable of 1,500 – 2,000 hp. A centrifugal blower at the engine rear delivered air to a separate carburetor for each cylinder row. The four valves per cylinder were operated by an overhead camshaft for each bank.

|

|

|

| 12Md (A39) | Renault's 1,500 - 2,000 hp Engine (A39) | |

|

|

| 4Pb (A39) | 4Pdi (A39) |

The 4P series, introduced in 1927, were direct-drive air-cooled vertical fours for light airplanes.

The 4Ps was the initial version with a 115 mm (4.528") bore, 140 mm (5.512") stroke and 5.817 l (354.98 in³) displacement. The 4Pa, 4Pb and 4Pbi followed. The 4Pb was representative of the early 4P engines; and upright inline four with a 5.2:1 compression ratio, it delivered 70 – 80 hp at 1,600 rpm, 95 hp at 2,000 rpm and weighed 135 kg (298 lb). Fuel and oil consumptions were 0.55 and 0.022 lb/hp/hr. It was 1,387 mm (54.6") long, 543 mm (21.38") wide and 922 mm (36.3") high. The individual cylinders consisted of steel barrels with integral cooling fins that were screwed and shrunk into aluminum alloy heads with bronze valve seats. The valves sat vertically in the head and were operated by push rods and rocker arms from a camshaft in the upper crankcase. The mixture was supplied via an exhaust-heated manifold by a Zenith 50J carburetor. Five plain main bearings secured the crankshaft by caps attached to the upper crankcase. A ball bearing carried the propeller thrust loads. The lower crankcase served as a 7 l (1.85 gal) oil reservoir. The connecting rods were made from duralumin forgings. Two magnetos mounted crosswise at the engine rear supplied dual ignition. The 4PBi was an inverted 4Pb.

The 4Pc was an air-cooled upright four developed from the 4Pb. With a 115 mm (4.528") bore, 140 mm (5.512") stroke, 5.817 l (354.95 in³) displacement and 5.8:1 compression ratio, it was rated 100 hp at 2,200 rpm and 120 hp at 2,300 rpm from a 139.7 kg (308 lb) weight. Each steel cylinder barrel was captured between the crankcase and cast aluminum cylinder head by four long bolts. The valve mechanism, similar to the 4Pb design, was fully enclosed. On each crankcase side were two mounting pads. Since the inverted engine required a dry sump lubrication system a very shallow cover replaced the deep sump used in the 4Pb. Two Scintilla magnetos with automatic advance were mounted inverted on pads provided on the aluminum casting that bolted to crankcase rear. A horizontal Zenith 50 HMI carburetor was attached to either a straight manifold's aft end or to a right-angle Tee that joined a manifold at mid-position. The 4Pci was an inverted 4Pc.

The 4Pdi, known also as the Bengali Junior, was a later development of the 4P series, and is representative of the later engines. It was an inverted inline four with a 120 mm (4.724") bore, 140 mm (5.512") stroke, 6.333 l (386.49 in³) displacement and 5.5:1 compression ratio. Rated 120 hp at 2,200 rpm, it delivered 145 hp at 2,350 rpm, weighed 144.7 kg (319 lb). Fuel and oil consumptions were 0.528 and 0.022 lb/hp/hr. The 4Pdi was similar in most respects to its smaller inverted companion, the 4Pci. The crankcase was cast from a special aluminum alloy and the joint for the upper magnesium cover slightly sloped toward the main axis at both front and rear ends. The nose piece at the propeller end supported a Viet air compressor that was driven by the camshaft end.

The 4Pei, a later and more refined Bengali model, retained the 4Dei bore and stroke, but had a 5.75:1 compression ratio and was rated 140 hp at 2,100 rpm and 500 m (1,640 ft). Weight was 144.7 kg (319 lb), length 1,280 mm (50.38"), width 480 mm (19.29") and height 708 mm (27.86"). Fuel and oil consumptions were 0.55 and 0.022 lb/hp/hr.

The 4Pgi, a companion Bengali with a 5.3:1 compression ratio, was rated l00 hp at 1,800 rpm and 500 m (1,640 ft) using 85 octane fuel. It weighed 140.2 kg (309 lb), had a 1,289 mm (50.07") length, 440 mm (17.32") width, and 700 mm (27.56") height.

For more 4P models and information on later series engines please see the Wikipedia Renault 4p Article

|

| 6Pdi (A39) |

The 6Pdi, an inverted Bengali inline six employing the 120 mm (4.724") x 140 mm (5.512") cylinders previously used on the four-cylinder engines, was introduced early in 1931. Displacing 9.5 l (579.73 in³) and with a 5.75:1 compression ratio, it was rated 180 hp at 2,200 rpm and weighed 204.6 kg (451 lb). Fuel and oil consumptions were 0.55 and 0.022 lb/hp/hr. Each of the two carburetors mounted on intake manifolds at the engine side were fed by individual fuel pumps. Two magnetos mounted on the crankcase cover top provided ignition. The engine was supplied with a Viet air compressor and Eclipse inertia starter mounting provisions.

The 6Pdis was an inverted supercharged inline six Bengali The 453 version was sea-level rated 220 hp at 2,400 rpm and weighed 235.4 kg (519 lb). The 454 maintained 220 hp to 2,000 m (6,562 ft) and weighed 253.6 kg (559 lb). The 455 maintained 220 hp to 4,000 m (13123 ft) meters and it weighed 259.5 kg (572 lb). Fuel and oil consumptions were 0.583 and 0.022 lb/hp/hr. The geared supercharged model produced 360 hp and weighed 234.5 kg (517 lb).

|

| Renault 438 (A39) |

The 438Coupe Deutsch 1934 was a supercharged 6Pq Bengali that won the 1934 Deutsch Cup Races. A single Stromberg carburetor was mounted on the centrifugal supercharger running 26,000 rpm at the engine rear. Intake air was drawn from the cylinder cooling jacket. A Ratier all-metal propeller with automatically-variable two-position pitch was fitted. The engine's bore was reduced to 109.75 mm (4.321") and with the 140 mm (5.512") stroke the displacement became 7.947 l (484.93 in³). Its normal rating was 300 hp at 2,900 rpm, but it produced 325 hp at 3,250 rpm. Forged aluminum alloy pistons produced a 6.0:1 compression ratio.

The 6Pfi was another Bengali model with the racing engine's dimensions and a 6.2:1 compression ratio but minus the supercharger. It was normally rated 170 hp at 2,100 rpm and weighed 199.6 kg (440 lb). Fuel and oil consumptions were 0.528 and 0.022 lb/hp/hr.

The Coupe Deutsch 1935 was a refined 1934 engine for the 1935 Deutsch Cup Races that produced 370 hp at 3,200 rpm. Renault prepared another engine for the 1935 Deutsch Cup Races, an air-cooled inverted 60° V-12 with a 96.75 mm (3.809") bore, 90 mm (3.543") stroke, 7.940 l (484.5 in³) displacement and 6.25:1 compression ratio. Its centrifugal compressor turned 27,000 rpm producing a 7.1 psi boost. It was rated 500 hp at 4,500 rpm. Fuel consumption was 0.682 lb/hp/hr, weight was 317.1 kg (699 lb). One of these engines, prepared especially for speed events, was rated 600 hp at 5,100 rpm.

|

| Renault 12V (A39) |

The 12V was a 3:2 geared air-cooled inverted 60° V-12 built for the 1936 Deutsch Cup Races. With a 93.75 mm (3.691") bore and 90 mm (3,543") stroke, 7.455 l (454.94 in³) displacement and 6.4:1 compression ratio was rated 450 hp at sea level. The supercharger turned 28,500 rpm and the dry weight was 318 kg (701 lb).

The 12VS was a 1.7073:1 geared water-cooled inverted 60° V-12 with a 115 mm (4.528") bore and stroke, giving a 14.334 l (874.71 in³) displacement. It was rated 450 hp at 3,500 rpm up to 4,000 m (13,123 ft). Weight was 394.2 kg (869 lb).

The 1938 air-cooled inline six series retrained the 120 mm (4.724") bore, 140 mm stroke and 9.500 l (579.74 in³) displacement used in most earlier sixes. However, new model designations were applied.

|

|

| 6Q-10 (Wiki) | 6Q-11 (Wiki) |

The 6Q.00 and 6Q.01 were unsupercharged direct-drive engines with 6.4:1 compression ratios differing only in propeller rotation direction. As viewed from the anti-propeller end, the 6Q.00 turned clockwise and the 6Q.01 anticlockwise. Both were rated 220 hp at 2,500 rpm and 500 m (1,640 ft). Dry weight was 227 kg (500 lb), length was 1,606 mm (63.23"), width 543 mm (21.38") and height was 931 mm (36.65").

The 6Q.02 and 6Q.03 were clockwise and anticlockwise engines, supercharged to give normal rated output up to 2,000 m (6,560 ft). With a 7.61:1 blower ratio, the weight increased to 256.3 kg (565 lb); length was 1,625 mm (63.97"), width 523 mm (20.59") and height 931 mm (36.65").

The 6Q.04 and 6Q.05 were clockwise and anticlockwise engines identical with the 6Q.02 and 6Q.03 except that the supercharger provides normal output up to 4,000 m (13,123 ft).

Several other 6Q models with different features and ratings were produced, each with LH/RH rotation variants: 6Q-06/07 = 233 hp; 6Q-08/09 = 240 hp; 6Q-10/11 = 230 hp; 6Q-18/19; 6Q-20/21 = 300 hp.

|

| Renault 12R (Wiki) |

The 1935 12R series direct-drive V-12s based on the 6Q Bengali inline sixes. With a 120 mm (4.724") bore, 140 mm (5.512") stroke, 19.000 l (1,159.47 in³) displacement and 6.4:1 compression ratio, the 12R was rated 450 hp at 2,500 rpm up to 4,000 m (13,123 ft). Weight was 377.4 kg (832 lb). Numerous variants with different ratings included: 12Rb = 470 ‑ 480 hp; 12Rc = 500 hp; 12Rm = 480 hp; 12Ro = 450 hp; 12R-00 = 500 hp, LH rotation; 12R-01 = 500 hp, RH rotation; 12R-02 =500 hp; 12R-03 = 500 hp; 12R-09 = 500 hp; 12R Spécial = 730 hp.

The 1938 12R-01 was a water-cooled V-12 with a 120 mm (4.724") bore, 140 mm (5.51") stroke, 19.000 l (1,159.47 in³) displacement and 6.4:1 compression ratio. It was rated 450 hp at 2,500 rpm and 3,600 m (11,811 ft), but produced 500 hp for takeoff. It weighed 384.6 kg (848 lb), was 1,840 mm (72.44") long, 750mm (29.53") wide and 920 mm (36.22") high. Fuel and oil consumptions were 0.616 and 0.024 lb/hp/hr. The articulated connecting rods were made from steel forgings. The centrifugal supercharger turned 11.7 times crankshaft speed and incorporated a slipping clutch to address crankshaft torsional vibration.

The 12Drs was a 1.401:1 geared water-cooled V-12 with a 130 mm (5.118") bore, 170 mm (6.693") stroke, 27.077 l (1,652.36 in³) displacement and 6.0:1 compression ratio. It was normal-rated 510 hp-at 2,200 rpm up to 1200 m (3,937 ft). Fuel and oil consumptions were 0.59 and 0.14 lb/hp/hr. Weight was 419 kg (924 lb), length was 1,884 mm (66.3"), width 724 mm (28.5") and height 970 mm (38.19"). A centrifugal supercharger was attached at the engine rear. The welded steel cylinders were fitted with two inlet and two exhaust valves actuated from an overhead camshaft carried in a housing bolted to the cylinder heads. S.E.V. magnetos mounted crosswise at the engine rear furnished dual ignition.

Renault built a 1.401:1 geared water-cooled V-12 with a 145 mm (5.709") bore, 150 mm (5.906") stroke and 29.723 l (1,813.83 in³) displacement. It produced 650 hp at 2,200 rpm up to 4,000 m (13,123 ft) and weighed 509 kg (1,122 lb).

|

|

| 12Drs (A39) | 18Jbr (A39) |

The 18Jbr was a 1.8584:1 geared water-cooled W-18 introduced in 1930 with a 125 mm (4.921") bore, 170 mm (6.693") stroke and 37.552 l (2,291.55 in³) displacement rated 750 to 850 hp at 2,100 rpm. This engine had plain spur reduction gear, weighed 515.3 kg (1386 lb), was 2,165 mm (85.24") long, 980 mm (38.58") wide and , and 1,123 mm (44.21") high. This engine apparently used cylinders common to 12Ja and 12 Jb engines.

A centrifugal supercharger delivered the mixture to each cylinder row through straight manifolds. The mixture was fed into the blower by two horizontal carburetors. A centrifugal oil cleaner was fitted, as in other Renault engines. Two magnetos were placed just ahead of the blower, and two fuel pumps and the water pump were located at the aft bottom.

Radials

The 9a, an air-cooled radial nine, was produced by Renault during 1928 and 1929. With a 125 mm (4.921") bore, 150 mm (5.906") stroke, 16.567 l (1,010.98 in³) displacement and 5.2:1 compression ratio, it was rated 250 hp at 1,820 rpm and weighed 269.9 kg (595 lb). Its was 1,216 mm (47.87") in diameter and 957 mm (37.16") long. Fuel and oil consumptions were 0.55 and 0.022 lb/hp/hr. Steel cylinder barrels with cooling fins, were screwed and shrunk into aluminum-alloy heads with aluminum-bronze valve seats. The valves were inclined in the cylinder head and were operated by enclosed push rods and rocker arms from a cam ring within the crankcase front with four cams per track running at 1/8 crankshaft speed and enclosed by the front crankcase cover. The cam cover also carried brackets for two magnetos that were driven by a transverse shaft. The barrel-type aluminum crankcase rear cover contained induction passages connected with an oil-heated Zenith 50 TJ carburetor. The forged one-piece single-throw crankshaft ran on roller hearings and a radial ball bearing carried propeller thrust loads. The master connecting rod had a split big end and H-section shank; the link rod shanks were tubular. Aluminum pistons were used, and pressure-feed lubrication was maintained by a gear pump.

|

|

| Renault 9Ca (A39) | |

The 9Ca was an air-cooled radial nine with a 140 mm (5.512") bore, 150 mm (5.906"), stroke, 20.782 l (1,878.41 in³) displacement and 5.5:1compression ratio. Rated 350 hp at 1,900 rpm, it delivered 435 hp at 2,100 rpm. It weighed 349.3 kg (770 lb), was 1,275 mm (50.19") in diameter and 1,184 mm (46.6") long. The ignition and valve operating mechanisms were at the engine rear. The exhaust ports faced forward, and the cylinder head cooling fins were arranged for improved cooling. The valve rocker boxes were cast integral with the aluminum cylinder heads, and had covers to completely enclosure the valve gear. Steel cylinder barrels with integral cooling fins and eight-bolt attachment flanges were screwed and shrunk into the cylinder heads. The main crankcase consisted of two sections joined in the cylinder plane. The two-piece crankshaft allowed a one-piece master rod. A centrifugal supercharger was fitted, and two Scintilla magnetos provided radio-shielded dual ignition. Starting was accomplished by a compressed air provided by a Viet compressor mounted on the rear cover with the other auxiliaries.

|

| Renault 7A (A39) |

The 7a was an air-cooled radial seven with a 100 mm (3.937") bore, 120 mm (4.724") stroke, 6.597 l (402.59 in³) displacement and 5.2:1 compression ratio. Rated 100 hp at 2,000 rpm, it delivered 131 hp at 2,200 rpm, weigh 129.7kg (286 lb), was 1,002 mm (39.45") in diameter and 969 mm (38.14") long. The cam rings and magnetos were at the engine rear along with the other auxiliaries. The two-piece aluminum crankcase was joined in the cylinder plane. Inclined valves were operated by exposed push rods and rocker arms supported by brackets held by studs to wide cylinder head pads. The aft-facing inlet ports were connected to the rear crankcase induction passage by nearly tangential pipes; the exhaust ports faced forward.

The 7b, with a 100 mm (3.937") bore, 117 mm (4.606") stroke and 6.432 l (392.53 in³) displacement, was rated 100 hp at 2,000 rpm, but delivered up to 120 hp at higher speeds. It weighed 139.7 kg (308 lb).

|

| Renault 9Fas (A39) |

The 9Fas, introduced in 1934, was a direct-drive air-cooled radial nine with a 154 mm (6.063") bore, 176 mm (6.929") stroke, 29.04 l (1,800.47 in³) displacement and 5.5:1 compression ratio. It was normal-rated 600 hp at 1,950 rpm and 700 m (2,296 ft) and takeoff-rated 680 hp at sea-level. Fuel and oil consumptions were 0.572 and 0.026 lb/hp/hr. Dry weight was 384.2 kg (847 lb), diameter was 1,355 mm (53.34") and length was 1,262 mm (49.68"). The push rods were at the engine front and the entire valve mechanism was fully enclosed. The composite cylinders had steel barrels and aluminum heads with pompadour cooling fins.

The 9Fasr was a 1.3699:1 geared 9Fas version with a 680 hp at 2,100 rpm normal rating up to 2,000 m (6,560 ft) and a 700 hp sea-level takeoff rating. Dry weight was 431 kg (950 lb) and the length was 1,382 mm (54.4").

|

| Renault 14Fas (A39) |

The 14Fas, a supercharged 14-cylinder two-row 9Fas companion with a 45.896 l (2,800.73 in³) displacement and 6.4:1 compression ratio, was first shown at the 1934 Paris Aeronautical Salon. Normally rated 1,000 hp at 2,000 rpm up to 4,000 m (13,123 ft), its maximum output was 1,100 hp. Dry weight was 583.8 kg (1,287 lb), diameter was 1,285 mm (50.58") and length was 1,499 mm (59"). Fuel and oil consumptions were 0.583 and 0.022 lb/hp/hr.

The 14Fasr was a 1.4815:1 geared companion to the 14Fas that was rated 1,000 hp at 2,000 rpm up to 4,000 m (13,123 ft) and weighed 628.7 kg (1,386 lb).

These two-row fourteen-cylinder designs employed a one-piece crankshaft supported on two roller bearings. Bronze-lined steel bushings comprised the crankpin bearings. Big-end master rod caps were retained by four bolts each.

|

| Renault 14T (A39) |

The improved 1937 14Fas and 14Fasr engines were given new model designations, but otherwise changed little. The 14T.00 and 14T.01 models were direct-drive engines weighing 630.5 kg (1,390 lb) delivered 1,020 hp at 2,000 rpm and 3,900 m (12,976 ft). Sea level takeoff rating was 970 hp. The supercharger turned 10.8 times crankshaft speed. The propeller rotation direction was the only difference between the two models; the 14T.00 rotated anticlockwise when viewed from the rear, and the 14T.01 rotated clockwise.

The 14T.02 and 14T.03 were geared engines differing in propeller rotation, as above. The two geared types both weighed 508 kg (1,120 lb). Overall length was 1,692 mm (66.61"). Normal rating was 1,000 hp at 2,000 rpm and 3m900 m (12,796 ft) with 940 hp the specified sea-level takeoff rating.

Diesels

At the December 1930 Paris Aeronautical Exhibition, Renault exhibited an experimental diesel radial nine. Renault had been studying V-12 diesels and was involved with secret studies of air-cooled inverted V-8 diesels delivering 500 ‑ 600 hp at 1,800 ‑ 2,000 rpm.

References

Angle, Glenn D, ed. Aerosphere 1939 (New York, New York: Aircraft Publications, 1940).

Anble, Glenn D, ed. Airplane Engine Encyclopedia (Dayton, Ohio: Otterbein Press, 1921).

Image Sources: A39 = Aerosphere 1939; AEE = Airplane Engine Encyclopedia; Flt = Flight Magazine; NARA = U.S. National Archives and Records Administration; UKNA = United Kingdom National Archives.

Wikipedia Renault Aircraft Engines Category