Download a Large Image of the Pratt & Whitney Medallion (870K)

Courtesy of Pratt & Whitney and Jay Apt

Pratt & Whitney

Pratt & Whitney Reciprocating Engine Specifications

Key to Pratt & Whitney Engine Designations (218K)

Index of Wasp Jr. and R-985 Designated Engines (158K)

Index of Wasp and R-1340 Designated Engines (262K)

Index of Twin Wasp Jr. and R-1535 Designated Engines (102K)

Index of Hornet, Hornet B, R-1690 and R-1860 Designated Engines (322K)

Index of Twin Wasp and R-1830 Designated Engines (261K)

Index of Twin Wasp and R-2000 Designated Engines (86K)

Index of Twin Wasp, Twin Hornet and R-2180 Designated Engines (53K)

Index of Double Wasp and R-2800 Designated Engines (586K)

Index of Wasp Major and R-4360 Designated Engines (568K)

Twin Wasp D (R-2000) Model Differences (2.4M). Courtesy of Wings Over the Rockies Museum and James Tegart

Pratt & Whitney Reciprocating Engine Production

Pratt & Whitney Customer Training Center and Museum

Pratt & Whitney Engine Paint Specifications

Researched and provided by Craig M. McBurney

Gray Paint

Originally provided by Kay and Ess Company of Dayton, Ohio. "No. 839 Blue Gray Airdry Enamel"

Military Specification: MIL-E-7729, Enamel, Gloss, For Aircraft Use, Gray

Black Paint

Military Specification: MIL-E-5557, Enamel, Heat Resisting, Glyceryl-Phthalate, Black

|

Download a Large Image of the Pratt & Whitney Medallion (870K) Courtesy of Pratt & Whitney and Jay Apt |

The Two Pratt & Whitney Companies

"Accuracy" and "Dependability"

by Jack Connors, PE

Pratt & Whitney Company

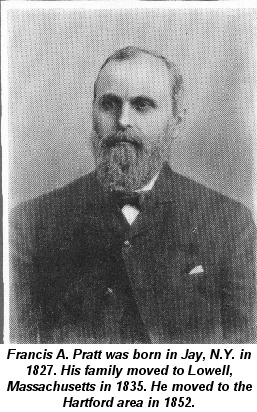

Two young machinists, Francis Pratt and Amos Whitney, working at the Phoenix Iron Works in Hartford, Connecticut founded the Pratt & Whitney Company in 1860.

"Not often does it happen that a Company founded upon rigid precepts of accuracy clings unswervingly to those precepts for seventy years. That is the record of the Pratt & Whitney Company. Its founders were men who saw the coming need for a degree of precision then undreamed of, and they determined that every product bearing their name should be the best that could be built."

"Accuracy, in itself, is not an end. Pratt & Whitney visioned that through accuracy would come ways of making interchangeable parts, and of making them in quantities at a fraction of previous costs. From this idea has grown the mechanical age in which we now live. It gave us sewing machines, bicycles, automobiles, aircraft, radios, vacuum cleaners and practically every mechanical device in use today."

|

Francis Pratt When he was 25 years old Pratt came to Hartford to work in the Colt Armory. Two years later the Phoenix Iron Works in Hartford hired him to be the plant superintendent. It was at Phoenix that he would meet a man who with him would create the means for precise mass production. |

|

Amos Whitney Amos Whitney and his father came to Hartford around 1850 to work at Colt’s Pistol Factory. Amos Whitney was reputed to be a hard worker -- putting in about 10 hours per day and hardly ever taking time off. He had the reputation of being a good executive and salesman. "He is perfectly straightforward in all dealings with men and there is no need for a contract with him if his word has been given." |

Messrs. Pratt & Whitney

"Not often does the world see such an example of perfect harmony between business associates as existed between Francis Pratt and Amos Whitney. Theirs was a noteworthy association which went far deeper than most. Mutual trust, complete understanding, a striving toward the same high ideal, all were part of that relationship.

In 1879 P&W financed the efforts of Harvard Professor William A. Rogers and George M. Bond from Stevens Institute of Technology to develop a comparator for measurements within one 50 thousandths of an inch. In addition, the P&W Company established the standard inch. By 1885 the P&W standard measuring machine was beginning to be known all over the world as the basis of the construction of recognized standards of length — now accurate to one hundred thousandth of an inch!

"This new idea of interchangeability had been thought of and talked about to some extent by Eli Whitney and Samuel Colt, but it remained for Amos Whitney and F. A. Pratt to make the idea practical on a large scale. As a result Pratt & Whitney Company became pioneers and leaders in developing and applying the new system of interchangeable manufacture. Much of the success of this system depended upon the development and use of accurate gages and trustworthy standards of length."

P&W's skill in manufacturing machinery for making guns brought many inventors to them for building their initial models. This list includes the Lee gun, predecessor of the Lee Enfield and the Medford — said to have been the progenitor of all bolt-action rifles. Mr. Mauser directed the manufacture of his famous rifle at P&W. The Sponsel gun, the deKnight machine gun and a Remington rifle were made in the Pratt & Whitney shop. In addition, Pratt & Whitney exported manufacturing machinery to Germany in the 1870s.

The Niles-Bement-Pond Company purchased the P&W Company in 1901. In 1904 it contracted with the Japanese government for the delivery of tools, gages and machinery. The Company manufactured 6-inch naval gun sights for the U.S government. In 1909 P&W won a contract with an Australian Arsenal in Lithgow to manufacture British weapons that had to be interchangeable with those made in England. The British were surprised that an American firm, using less than half the machinery as the British, could make parts interchangeable with those made in England.

P&W expanded to meet the demands of the blooming automobile industry. Later a further expansion came at the outbreak of WWI. Gun-making machinery was in huge demand. NBP bought the buildings next to P&W, which were formerly used by the Pope Manufacturing Company — an area to be used in 1925 by another Pratt & Whitney company.

|

Pratt & Whitney Aircraft Co. Frederick B. Rentschler, former president of Wright Aeronautical Corporation, came to Hartford to explore the possibility of founding an aircraft engine company in the Hartford area. When he met with Clayton Burt, president of the Pratt & Whitney Company, all the ingredients for success were right there in that initial meeting – proven leadership, aircraft engine technology, facilities and capital. Rentschler and his partner, George J. Mead were enthusiastic pioneers in the development of dependable, air-cooled engines. In July 1925 a contract was drawn up between (1) the Pratt & Whitney Company and (2) Frederick Rentschler and George Mead with half the shares of stock divided between the Pratt & Whitney Company and the combination of Rentschler and Mead. The Pratt & Whitney Aircraft Company was a separate company under the sole direction of Mr. Rentschler. |

|

Frederick Rentschler could not have selected a more appropriate name than "Pratt & Whitney Aircraft Company" for his new company. The insertion of the word "Aircraft" gave an already world-famous name for "accuracy" the added connotation of "dependability." |