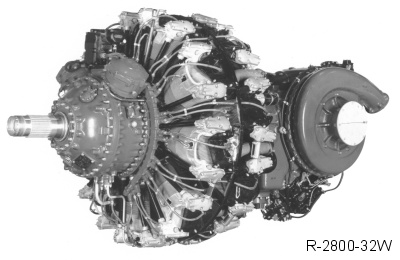

Pratt & Whitney Double Wasp (R-2800)

Compiled by Kimble D. McCutcheon

Published 10 Mar 2002; Revised 6 Jul 2020

Double Wasp CA Series Description

Type = 18-cylinder two-row air-cooled radial

b>Bore = 5.75" Stroke = 6.000" Displacement = 2,804.5 in³

Cylinders are built up of forged aluminum heads with integral valve mechanism housings, screwed and shrunk onto forged steel cylinder barrels. Forged aluminum sleeves in which deep-cut cooling fins have been machined (muffs), are shrunk over the central portion.

Each cylinder has one inlet and one exhaust valve. The inlet seats in a bronze insert and the exhaust on a steel insert, both of which arc shrunk into the head. Pressure baffles are provided to enhance cooling.

Forged aluminum pistons are of the full-skirt type. Each piston is fitted with three compression rings, dual oil control rings and one oil scraper ring. The top compression ring is chromium plated on the face that bears against the cylinder wall.

Each of the two master rod assemblies consists of a one-piece master rod and eight "I" section articulated rods attached by knuckle pins. Master rod bearings are one-piece steel shells covered on the inside and outside with lead-silver. Each articulated rod has a bronze bushing on its piston pin end. The other end rides on a silver-plated knuckle pin.

The crankshaft is machined from three steel forgings having two throws that divide at the crankpins and are joined to together by face splines and bolts. The crankshaft assembly is supported by steel-backed lead-silver bearings mounted in the front, center and main crankcase sections. Reciprocating and rotating part weights are counteracted by weights, the front and a portion of the rear being mounted as bifilar dampers. Mounted at each end of the crankshaft arc two counterbalances, revolving at twice crankshaft speed to eliminate second order "whirl".

The crankcase is composed of three forged aluminum alloy sections held together by through bolts. The nose section houses the reduction gears and torquemeter and has provisions for a full-feathering;, reversible propeller governor.

The supercharger section is attached to the rear of the main crankcase section and also houses an impeller. The intermediate rear case is attached to the supercharger section. It supports at its forward face a vaned diffuser plate and provides a mounting surface for a pressure carburetor. The rear section has mounting pads for accessories.

The valve gear, induction system supercharger, ignition system, lubrication system, reduction gear and accessory drives are substantially the same as the Twin Wasp. The ignition system is optionally high or low voltage. Water injection equipment may be used with the "CA" Double Wasp to give added power for takeoff and emergencies.

|

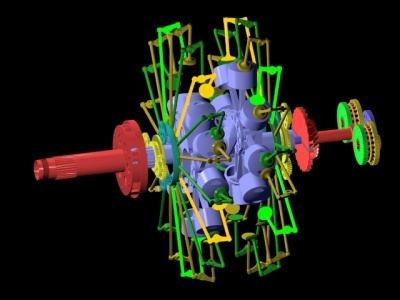

Ralph Jones has created a beautiful series of R-2800 component animations. Stills from this animation set can be viewed HERE. |