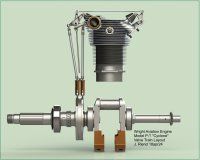

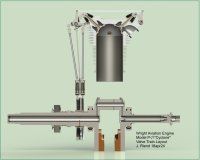

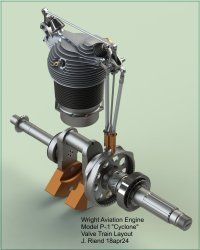

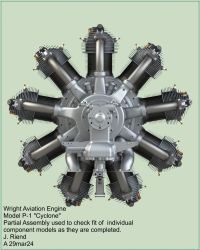

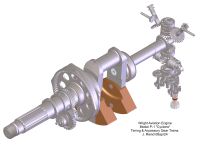

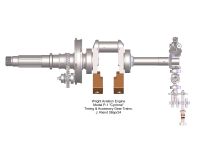

Wright Aviation Engine, Model P-1 "Cyclone"

by J. Riend

Published 1 Mar 2024; Revised 19 Apr 2024

| Early in 1925, the Wright Aeronautical Corporation was busy working on the first large 400-horsepower class radial engine that was to become the Model P-1 Cyclone, the forerunner of a very successful aircraft engine line. |

Wright P-1 Drawing Quick Reference

| Crankcase Layout | Cylinder | Valve Train | Partial Assembly | Gear Trains | Starter Assembly |

1 March 2024

To date there has been very little technical information available about these ground breaking engines. There are a few photographs available online at AEHS and the National Air and Space Museum (NASM), and some endurance test run documents at NASM; that’s about it. There are however the original Wright drawings of these engines stashed away in the WAD engine drawing microfilm archive at Wright State University.

I originally started 3D modeling the Wright P-2 engine because it appeared to have the least number of missing drawings (yes, some drawings are missing, not filmed or unreadable). I had hoped to be able to complete the entire engine. While working on the P-2 supercharger section, I continued searching the archive for additional drawings of these (P-1, P-2 and R-1200) engines and got very lucky, hitting on a version of the P-1 cylinder head drawing. It was actually the P-1, and its unique and elaborate valve train mechanism, that piqued my interest in researching the large Wright radials. Having found that cylinder head drawing, I now have a complete P-1 drawing set and will be able to complete that project. I decided to postpone modeling the P-2 and move forward on the P-1 project.

|

|

|

|

|

| Wright Aviation Engine, Model P-1 (Photos from NASM (CCO)) | ||||

The P-1 renders and drawings that follow are my interpretation and faithful representation of the Wright drawings. The scans of the original drawings are not always fully legible, show every detail and may have questionable dimensions. These discrepancies can usually be overcome by comparing dimensions and features on associated components. However, in some cases (very rarely) there is not enough information or modeling skill set to fully render some features details. Now, for your enjoyment, the historical P-1 Cyclone.

17 March 2024

In the interest of full disclosure, the P-1 cylinder head intake and exhaust runners were designed with equal (more or less) flow area along their length. Unfortunately, these runner features exceed my current level of 3D modeling expertise. As a result, I opted to model the runners with uniform width, leaving out those features, which means that the normal bulges in the runners around the valves are not present in this model.

An interesting feature of the cylinder head and sleeve assembly is the very long (26 turns) 6-5/16"-16 thread. The sleeve is assembled with an 0.0185" interference fit. The components must have been assembled at room temperature, because the change in pitch over the engagement length would have made it impossible to screw the sleeve in if the head were heated for a shrink fit. Wright obviously had years of experience with these fine-threaded sleeves in its Hispano-Suiza engines. Anyone have any documentation on how they actually performed this assembly operation?

Another interesting feature of the P-1 is the tungsten steel alloy (10040-W60A US Air Corps) used for both the valves and valve guides. They must have squirted grease under the spiral springs thru holes in the lower spring washer. These engines had to be a real mess to fly behind.

|

|

|

|

|

|

|

|

|

|

| Cylinder Head | Cylinder Head and Sleeve Assembly | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|