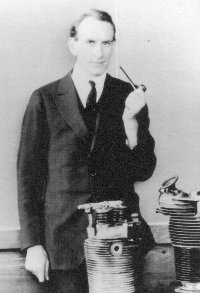

In the U.S., almost the only proponent of the air-cooled engine during World War I was the Lawrance Aero Engine Company. This small New York City firm had produced the crude opposed twins that powered the Penguin trainers, which were supposed to be the stepping-stone to the Jenny for aspiring military pilots. The Penguins were not intended to fly but apparently could taxi at a speed that would provide some excitement for trainees as they tried to maintain directional control and develop some feel of what flight controls were all about. The Lawrance twins, which can be seen in many museums, had directly opposed air-cooled cylinders and a crankshaft with a single crankpin to which both connecting rods were attached. This arrangement resulted in an engine that shook violently at all speeds and was therefore essentially useless for normal powered flight. After World War I, some attempts were made, generally unsuccessful, to convert the Lawrance twins into usable engines for light aircraft by fitting a two-throw crankshaft and welding an offset section into the connecting rods. This proves that the desire to fly can be very strong indeed in some individuals.

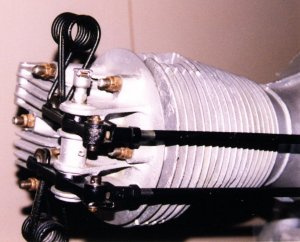

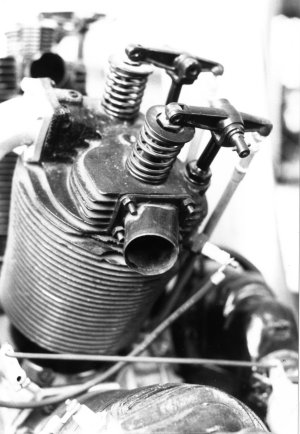

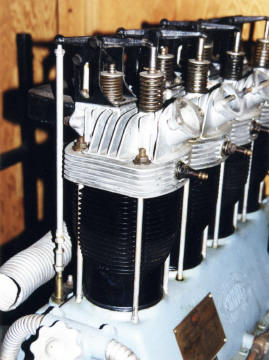

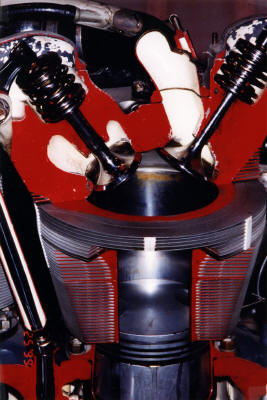

| The hairpin valve springs pictured to the left were possibly pioneered by Salmson in 1911, and later used not only on British single-cylinder racing motorcycle engines, but also by Ferrari and others into the 1950s. This use was a response to the same problem that led to desmodromic valves at Ducati, Norton (test only) and Mercedes - namely the fatigue of coil springs from "ringing". Hairpin springs ran cool because they were exposed, and they were less subject to fatigue. They could also be changed without engine disassembly. Around 1964 cleaner steels produced by vacuum remelting became available in quantity, making possible the manufacture of highly fatigue-resistant spring wire. Previous wire was made from electric furnace steel - then the cleanest available. Vacuum remelted steel wire made desmo and hairpins redundant. Today Ducati engineers respond to the question "Why still desmo?" much as Bosch engineers did to the 1945 question "why direct injection when carbs were so much simpler?". They said that once they'd started down that road, it was simpler to continue rather than start over with another technology. Kevin Cameron |