The Making of a Flight Engineer

Part 2: Back Stateside — C-119s from Miami to Greenland

by Floyd J. Stelly

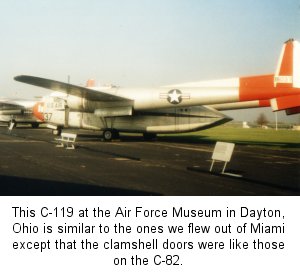

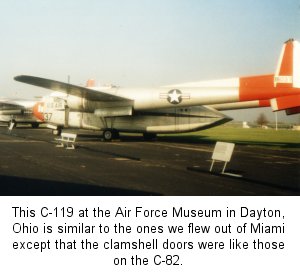

When I arrived in Miami for my new assignment in the C-119 squadron, I immediately saw big differences when compared to the C-82. The Pratt & Whitney R-4360 engine with its 28 cylinders, 7 magnetos, and anti-detonation injection (ADI) producing 3,500 hp was really awesome. The propeller was reversible with an oil system independent of the engine oil system. If leakage occurred, engine oil could be pumped to the propeller reservoir to complete the flight. All takeoffs were made wet (with ADI), 2,700 rpm and 60 in hg of manifold pressure. Dry rating was 3,250 hp. After climb power was set, the variable speed, single-stage supercharger maintained this manifold pressure.

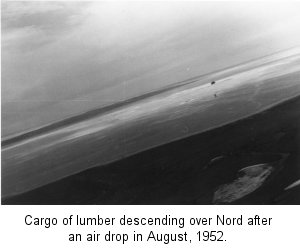

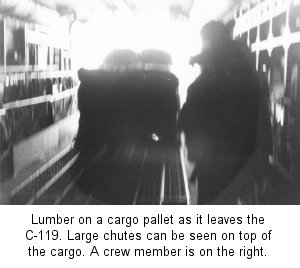

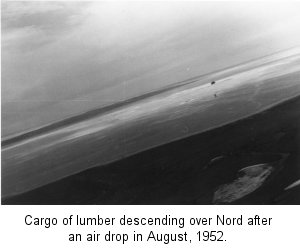

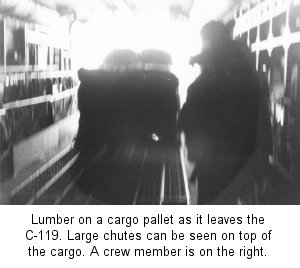

My first long range mission was to Thule Air Base in northwestern Greenland for airdrops at a remote weather station in the northeast of Greenland called Nord. Our plan was to remove the clamshell doors, load two pallets with cargo and drop them via parachute over the station. We loaded maximum fuel for this non-landing round trip. Rear door removal created considerable drag and fuel was critical. The runways at Thule were under construction so we were using a short asphalt runway, which was lined up for an over-water departure where large ice floats could be seen.

My first takeoff was an experience I'll never forget. After liftoff and gear retraction, the right engine started backfiring and showed a drop in torque pressure and rpm. We feathered that engine and the pilot made a gradual 270-degree right turn to line up with a runway that was completed but was not officially open for use. We lowered the gear and touched down with the left engine turning 2,700 rpm, 60 in hg of manifold pressure and anti-detonation injection (ADI). The aircraft and engine performance really impressed me. The later C-119F with the compounded Curtiss-Wright R-3350 could never have accomplished this feat. It would have been impossible to jettison the chained down pallets in time for this emergency landing.

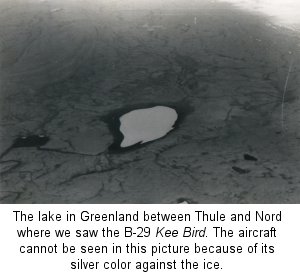

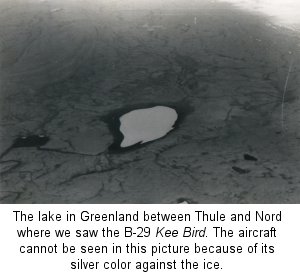

On my first flight to Nord after this incident, we saw a plane on the ice midway into our flight and reported it by radio. We were told it was Kee Bird, a B-29 that got lost and ran out of fuel. The crew was rescued. Years later, a PBS Nova documentary entitled "B-29 Frozen in Time" chronicled the attempt by race pilot and salvage pilot Darryl Greenamyer to repair and fly the aircraft out. Sadly, it caught fire and was lost while taxiing for takeoff.

Because our fuel burn was so high, a road grader was dropped in two parts on pallets and used to construct a temporary runway. This worked fine so we continued to fly with doors installed and carrying cargo in the usual manner. We returned to Miami after all cargo delivery was completed. Later, in November of that year we had another assignment to drop paratroopers in Alaska and test the arctic clothing they wore. This was also for us to experience cold weather operation. We used oil dilution after the last flight of the day. This worked OK in Anchorage during engine starts, but further north at Fairbanks the engines had to be preheated for a successful start. I don't recall one starter being replaced in spite of the long slow process of moving 28 pistons in diluted 50 weight oil.

Flights to the drop zone were routine except on one occasion fog covered the whole area, so we had to return to base. This created a big commotion among the jumpers because none had ever landed in a plane and thought it would bring bad luck. After a month, we were happy to be returning to sunny Miami.

The squadron received many new planes from the Fairchild and Kaiser factory and our job was to fly and clear any discrepancy we found. The planes were then sent to other squadrons. These new aircraft were the C-119F models powered by R-3350s with power recovery turbines (PRT) and ADI. They were rated at 3,500 hp wet but I never believed this to be correct. The cylinders had lots of leakage on compression test and the PRTs had many cracks in the turbine blades and cooling caps. The ADI was only used on the first flight after an inspection or in an emergency. No reason was given for this procedure but I suspect it had to do with the PRT.

The high demand for the R-4360 on the B-36, C-124, B-50, and the C-97 was probably the reason for the changeover to the R-3350. My last assignment in this squadron before going to C-124 flight engineer school was temporary duty at Eglin AFB in north Florida. There, I helped work on and fly the one-of-a-kind XC-120 Packplane. This was a C-119B conversion of an experimental detachable fuselage transport. The Packplane could be flown with or without the pack. Without the nose gear installed in the cargo pack, each boom had 2 landing gears. One was in the normal position and one forward extending, serving as a nose gear. This was very odd looking and created lots of drag. No orders were placed for this model after military evaluation.

My stay was cut short when I was ordered to report to Chanute AFB for C-124 flight engineering training.

For more information about the C-119, including great images, please visit The Aviation Zone C-119 Page

|

|

|

|

|

Part 1: C-54s, DC-4s and C-82s in Europe

Part 3. Stateside - C-124s

Part 4. Airline Experiences – Lockheed Constellations, Douglas DC-6s and DC-7s

Part 5. Airline experiences – Lockheed L-188 Electra

Part 6. Airline experiences – Turbojets