The Making of a Flight Engineer

Part 1: C-54s, DC-4s and C-82s in Europe

by Floyd J. Stelly

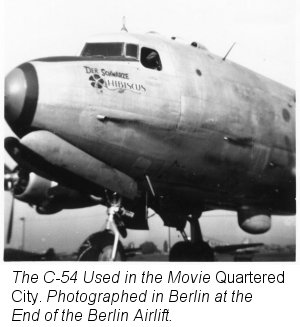

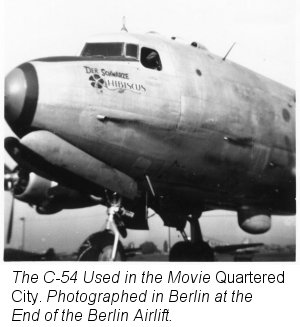

After graduating high school, the local Air Force recruiter got me a letter guaranteeing acceptance in the A&E Mechanic School in Biloxi, Mississippi—once I had completed basic training. The school taught all aircraft systems. Those who came in later received specialist training on one system only. Near the end of my training, there came a call for Berlin Airlift Operations volunteers. I jumped at this chanced and after completing the C-54/DC-4 Specialist Training Course, was sent to Wiesbaden, Germany. There, I was an assistant crew chief until the airlift ended.

|

I did the routine maintenance required after the plane made a round trip to Berlin. Any discrepancy was repaired while the plane was being loaded and fueled. The cargo was usually coal in sacks. The R-2000 was a good engine with most of its problems confined to spark plugs. Usually a mag drop called for a plug change. Sometimes the magneto itself was defective. We had what was called "crossover leads" that were used to test the magneto by using one magneto to power the distributor portion of the other. Plugs were reconditioned and never tested under pressure before installation. They were coated with cosmoline before being packaged. Before the plugs were installed, this had to be removed using 100-octane fuel. Sometimes the plug change didn't clear up the problem; probably because of the cleaning procedure.

The 25, 50, and 100-hour inspections were done with the help of German civilians supervised by our mechanics. We kept this operation going around the clock until the airlift ended. All military aircraft were then returned to their squadrons and civilian planes to their airlines. It's unbelievable what coal dust can do to the interior of a plane. You can never get it all cleaned out. I'm sure if any of these aircraft are still around there is coal dust between the riveted seams of the fuselage.

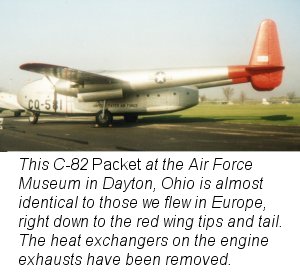

I had a choice of staying in Germany, which I accepted. We attended ground school on the C-82 Packet when it started to arrive. Everyone was awe-struck by the systems in this new arrival. The C-54 systems were powered by hydraulics. The C-82 had an electrically powered hydraulic pump for the brake system. Everything else—landing gear, wing flaps, cowl flaps, and the monorail system—were all electric. Large clamshell doors in the rear and two lightweight ramps allowed you to drive a couple of vehicles on board. The aircraft could also carry cargo, paratroopers or litter patients. An overhead monorail system allowed dropping duffle-bag-sized containers with a parachute attached through an opening in the center cargo compartment floor.

|

Our squadron transferred from Wiesbaden to Rhein Main Air Base in Frankfurt, about 25 miles away. It was there I became a flight crewmember and my career as a flight engineer began. I spent lots of time in England and France dropping their paratroopers on practice jumps. Most jumpers liked the plane because of the easy exit. I was sent to Farnborough, England on temporary duty where the British were experimenting with parachute dropping cargo on two large pallets. The rear clamshell doors were removed and a section of rollers was bolted to the floor to mount the pallets. Over the drop zone and clear of the aircraft, the chute was deployed. This worked well and was also used on the C-119s after I returned to the states.

A small V-2 cylinder APU was installed on the front floor of the cargo compartment. This was used during all ground operations, taxiing, takeoff and landings. Two heat exchangers were installed in each engine exhaust system as a wing anti-icing and cockpit heat source. The fuel system consisted of four fuel tanks. These were a constant source of problems because of leaks in the rubber bladder tanks. Once a leak was detected, we defueled until the leak stopped. We continued flying until new tanks were available. Most leaks occurred near the top so we were still able to operate with a sizable amount of fuel.

The flight engineer operated the landing gear and wing flaps on command. Also, as necessary, he operated the cowl flaps, boost pumps, fuel selectors, fuel cross feed, and carburetor heat. Every morning, wherever we were, the aircraft was preflighted. This included a walk around and engine run-up. When scheduled, most flights were able to depart without a delay. We visited were France, England, Italy, Syria, Egypt, Libya, Turkey, Denmark, Sweden, and Iceland.

After spending three years in Germany, which was the maximum you could stay, I was reassigned to a C-119 squadron based at Miami International Airport. Most of my friends were sent to Big Springs, Texas. I was accused of having political connections, but it was pure luck.

For more information about the C-54, including great images, please visit The Aviation Zone C-54 Page

For more information about the C-82, including great images, please visit The Aviation Zone C-119 Page

Part 2. Back Stateside – C-119s from Miami to Greenland

Part 3. Stateside - C-124s

Part 4. Airline Experiences – Lockheed Constellations, Douglas DC-6s and DC-7s

Part 5. Airline experiences – Lockheed L-188 Electra

Part 6. Airline experiences – Turbojets