Dayton Aircraft Engines

by Jay Smith

Published 15 Nov 2020

Dayton Bear (Page) |

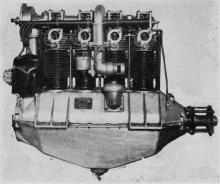

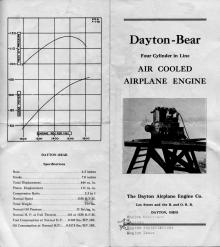

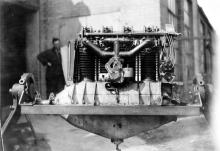

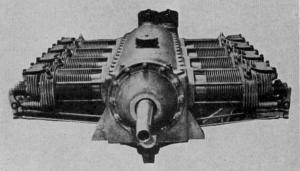

The Dayton Airplane Engine Company was organized in Dayton, Ohio in late 1927, but moved to Pawtucket, Rhode Island during 1930. Starting in 1928, it obtained about 1,600 war-surplus Hall-Scott four-cylinder inline A-7-A engines and began converting them from water-cooled to air-cooled engines. Photos of the Hall-Scott A-7 from the Smithsonian National Air and Space Museum depict the same crankcase, overhead camshaft, and magneto location as the Dayton “Cub,” later called the Dayton “Bear.” |

|

|

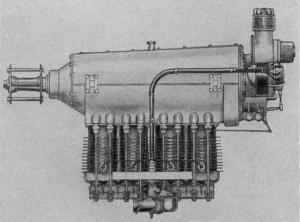

| Hall-Scott A-7-A (NASM) |

The Dayton Bear had a bore of 4.5", a stroke of 7.0", displaced 444 in³, and produced 110 bhp at 1,550 rpm. The Hall-Scott A-7 had a 5.25" bore, 7.00" stroke, displaced 606.1 in³, and produced 100 bhp at 1,400 rpm. Probably the Dayton’s air-cooled cylinders necessitated a smaller bore because of its finned cylinders.

Available images and documentation show the Dayton’s carburetor to be located on either side. Apparently, earlier engines located the carburetor on the left and later engines on the right so the hotter exhaust side received a more direct propeller blast. Hall-Scott carburetors were on the left. Long bolts from the cylinder heads to the aluminum crankcase secured the Dayton’s and Hall-Scott’s cylinder heads. Both the Dayton and Hall-Scott featured a five-main-bearing crankshaft running in Babbitt-lined steel-backed inserts, and both engines used pressure fed oil to the crankshaft and camshaft bearings. Connecting rods were steel forgings machined all over, big ends bronze-backed and babbitt lined with the small end having a bronze bushing for the case-hardened full-floating piston pins in cast aluminum pistons with three rings above the piston pins. The overhead camshaft is similar to that of the Liberty V-12, not surprising as Elbert J. Hall helped design the Liberty V-12. The Dayton Bear received Department of Commerce Approved Type Certificate No. 11 on 4 Apr 1929.

|

|

|

|

|

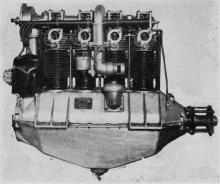

| Dayton Bear (Aerosphere 1939) |

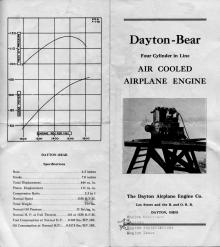

Dayton Bear Brochure (NARA) |

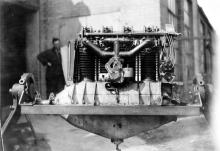

Dayton Bear Under Test, 1928 (NARA) |

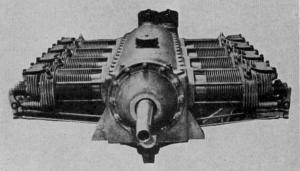

Dayton-Grant (Aerosphere 1939) |

Dayton Dragon (Aerosphere 1939) |

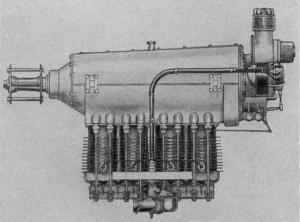

Other engine designs proposed by Dayton were a six-cylinder of 225 bhp and an air-cooled eight-cylinder of 350 bhp. The six-cylinder wasn’t built and the eight-cylinder Dayton-Grant appeared only as an experimental air-cooled horizontally-opposed engine of 764 in³. Dayton specified it as developing 225 bhp at 1,800 rpm, 240 bhp at 2,000 rpm, and a reduction gear version 280 bhp at 2,500 rpm. The similar Lycoming IO-720 horizontally-opposed engine (from the 1960s and 1970s) gives 400 bhp at 2,650 rpm. The Dayton-Grant and the Lycoming are similar with overhead valves operated by pushrods and rocker arms. The Dayton-Grant’s camshaft is below the crankshaft, whereas the Lycoming camshaft is above the crankshaft.

Another air-cooled in-line four-cylinder (50-55 bhp at 1,950 rpm) was the Dayton Flight, a design bought from the Pheasant Aircraft Co. of Fond du Lac, Wisconsin. Nickel-steel cylinders with aluminum heads were mounted on an aluminum-alloy crankcase, with full-pressure lubrication and a dry sump. The Wikipedia article “Pheasant Aircraft Company” pictures an unnamed upright air-cooled in-line four-cylinder engine, without the dual Robert Bosch magnetos used with the Dayton Flight.

Dayton’s Dragon engine was an inverted four-cylinder in-line with a 4.00" bore, 4.25" stroke, displacing 213.6 in³ and producing 62 bhp. It was similar to the Cirrus Hermes (348 in³) and the De Havilland Gipsy III (319 in³), and about the size of the Continental O-200 horizontally-opposed air-cooled engine used in Cessna 150s.