Selected Early Engines

Galloway, Gnome, Gnome-Rhone, Green, Gyro

Compiled by Kimble D. McCutcheon

Published 11 Jun 2022; Revised 16 Jun 2022

Galloway

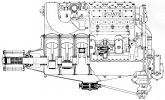

The original B.H.P. engine was designed by Major Frank Halford in collaboration with Sir William Beardmore and Mr. T.C. Pullinger, from which initials the engine got its name. Work to develop a light high-powered six-cylinder engine, which at that time was not available, but greatly needed by the British Air Service on the Western Front was started early in 1916. Since time was an important factor, the Arrol Johnston Co., Ltd. immediately set about to enlarge the 120-hp Beardmore engine to give at least 160 hp. This larger engine was successful and was used extensively in place of the 120-hp. model. The first B.H.P. engine was completed in June 1916. As most British engine manufacturers were then engaged in important production, a new company, the Galloway Engineering Co., Ltd., was formed to exploit the new B.H.P. design and factories were built at Dumfries, Scotland. The B.H.P. design was known as the Galloway Adriatic.

The British Air Service soon realized that the manufacturing facilities were insufficient for the numbers required and asked Siddeley-Deasy Co. of Coventry, England to also build the B.H.P. engine. Large-scale production levels were reached in very short time. These engines, after having been completely redesigned by Siddeley-Deasy, became known as the Puma, and were adopted as the standard six-cylinder vertical water-cooled engine by the Royal Air Force. Both the Galloway and the Siddeley firms built larger models patterned after the original B.H.P. designs.

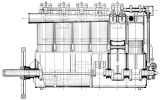

| Adriatic (AAE) |

The Galloway Adriatic was a water-cooled vertical six-cylinder with a 145 mm (5.709") bore, 190 mm (7.480") stroke and 18.825 l (1148.8 in³) weighing 685 lb, or 2.98 lb/hp. Fuel consumption was 0.517 lb/hp/hr and oil consumption was 0.0315 lb/hp/hr. Two Zenith carburetors furnished the mixture. Dry-sump lubrication used a gear pump to delivered oil at 20 psi to the bearings. Two fellows EM6 magnetos furnished dual ignition. The cylinders were constructed in groups of three barrels screwed into a single iron head casting. A steel stamping jacketed the three cylinders.The camshaft, supported in an aluminum housing extending the entire engine length, operated directly upon two exhaust valves in each cylinder. A large inlet valve in each cylinder was operated via a rocker arm. The inlet valve opened 7° late and closed 43° late, the exhaust opened 58° early and closed 12° late. The six-throw, seven-main-bearing crankshaft was supported by individual bearing caps using long bolts that supported the bearing caps through steel reinforcements from underneath; these were also used to hold down the cylinders. The H section shank connecting rods had four-bolt caps. Three compression rings were fitted to each aluminum alloy piston and an oil scraper was located below the piston pin.

The Atlantic, a 60° V-12 using Adriatic components and a 37.650 l (2,297.5 in³) displacement, was rated 500 hp at 1,500 rpm The two rows of six cylinders were each divided into two blocks of three. Claudel H.C.7 carburetors, located in the Vee, provided mixture, and two B.T.H. Type A.V.12 magnetos were mounted on the crankcase just outside the cylinders. Fuel consumption was 0.53 lb/hp/hr, and oil consumption was 0.068 lb/hp/hr. The inlet valve opened 8° late and closed 55° late; the exhaust valve opened 48° early and closed 16° late. Dry weight was 1,210 lb, or 2.4 lb/hp.

|

|

| Galloway Atlantic (AEE) | |

Gnome

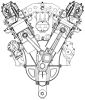

Although the air-cooled rotary was invented by Farwell in the U.S., its popularity was due to the skillful Gnome designs originated in 1908 by M. Laurent Seguin of France. Gnome engines played an important part in aviation development, particularly from 1909 to 1914, when they set so many important records. The Gnome designs were copied in part by several later rotary engine designers. The Socicta des Moteurs Gnome et Rhone, 3 Rue I a Boetie, Paris, France; The Gnome and Le Rhone Engine Co., Ltd., 47 Victoria St., S. W. London, England; La Socicta Italiana Motori Gnome and Rhone, 73 Strada Veneria, Madonna di Compagna, Italy; and the General Vehicle Co., Long Island City, NY, USA were all authorized Gnome engine builders.

|

| Gnome 2-Valve (AEE) |

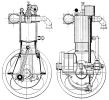

Nearly all Gnome engine parts were made from nickel steel. The cylinders had integral circumferential cooling fins and clamped between the crankcase halves. The built-up crankshaft rear section was hollow so that oil could be supplied to the crankpin from a plunger pump and so mixture from a rear-mounted carburetor could reach the crankcase. The articulated H-section connecting rod system featured a master connecting rod mounted upon large ball bearings. The fixed crankshaft supported the rotating mass of crankcase and cylinders upon ball bearings. Individual front-mounted cams (one for each cylinder) operated the exhaust valves. The original Gnome engines had an exhaust being in the cylinder head and an inlet valve in the piston head, where it operated automatically. The later Gnome monosoupape rotary appeared 1913 and had only one valve in the cylinder head that functioned principally as an exhaust but also as an inlet by admitting air during the suction stroke. A rich mixture entered the combustion chamber from the crankcase through ports in the cylinder lower end when the piston was at the lower end of its stroke and the rich mixture was then diluted by the air already in the cylinder.

The first Gnome engine had five cylinders, 100 mm (3.937") bores and strokes, a 3.927 l (239.6 in³) displacement and produced 34 hp at 1,300 rpm. Its weight was 132 lb, or 3.9 lb/hp. A seven-cylinder 50 hp model was also built along the same lines.

|

| Omega (AEE) |

The Omega, a seven-cylinder rotary with a 110 mm (4.331") bore, 120 mm (4.724") stroke and 7.983 l (487.2 in³) displacement was rated 50 hp at 1,200 rpm. Fuel consumption was 0.59 lb/hp/hr and oil consumption was 0.185 lb/hp/hr. Dry weight, including Bosch magnetos, was 172 lb, or 3.44 lb/hp. The diameter was 33" and the length was 31".

The Sigma, a seven-cylinder rotary with a 120 mm (4.724") bore and stroke, and a 9.5 l (579.7 in³) displacement, was rated 60 hp at 1,200 rpm. Its weight was 192 lb, or 3.2 lb/hp. Its diameter was 34.2", and its length 44.4".

The Gamma, a seven-cylinder rotary with a 130 mm (5.118") bore, 120 mm (4.724") stroke and 10.292 l (628.1 in³) displacement was rated 70 hp at 1,200 rpm.

The Lambda, a seven-cylinder rotary with a 124 mm (4.882") bore, 140 mm (5.512") stroke, 11.835 l (721.6 in³) displacement was rated 80 hp at 1,200 rpm. Fuel consumption was 0.59 lb/hp/hr and oil consumption was0.185 lb/hp/hr. Seight was 207 lb, or 2.59 lb/hp, diameter was 36.3" and length was 44"

The Delta, a nine-cylinder rotary with a 124 mm (4.882") bore, 150 mm (5.906") stroke 16.303 l (994.9 in³) displacement was rated l00 hp at 1,200 rpm. Fuel consumption was 0.59 lb/hp/hr, and oil consumption was 0.185 lb/hp/hr. Weight was 297 lb, or 2.97 lb/hp, diameter was 40.2" and length 45.3".

|

| Omega-Omega (NARA) |

The Omega-Omega, a double-row 14-cylinder rotary with Omega cylinders, displaced 15.966 l (974.3 in³) and developed 120 hp at 1,200 rpm. Dry weight was 310 lb, or 2.58 lb/hp, diameter was 32.5" and length was 49.5".

The Gamma-Gamma, a double-row 14 cylinder rotary using Gamma cylinders, displaced 20.584 l (1,256.1 in³), was rated 130/140 hp at 1,200 rpm. Weight was 287 lb, diameter was 34.2" and length was 439.6".

The Sigma-Sigma, a double-row 14-cylinder rotary using Sigma cylinders, displaced 19.0 l (1,159.5 in³) and was rated 120 hp at 1,200 rpm. Weight was 298 lb, or 2.48 lb/hp, diameter was 34.2" and length was 49.8".

The Lambda-Lambda, a double-row 14-cylinder rotary using Lambda cylinders, displaced 23.67 l (1,444.4 in³) and was rated 160 hp at 1,200 rpm. It weighed 396 lb, or 2.46 lb/hp. Diameter was 36.7" and length was 49.8".

The Delta-Delta, a double-row 18-cylinder rotary using Delta cylinders, displaced 32.606 l (1,989.7 in³) and was rated 200 hp at 1,200 rpm. It weighed 540lb, or 2.7 lb/hp, had a 40.2" diameter and a 54.1" length.

|

|

|

| Type A | Type B-2 (NARA) | |

The Gnome Type A, the first monosoupape design, had seven cylinders with a 110 mm (4.331") bore, 150 mm (5.906") stroke and a 9.978 l (608.9 in³) displacement. It was rated 80 hp at 1,200 rpm. The diameter was 35.3" and the length was 39.3".

The Gnome Type B-2, a nine-cylinder monosoupape rotary with Type A cylinders, was rated 100 hp at 1,200 rpm. It displaced 12.829 l 782.9 in³, weighed 272 lb, was 37.4" in diameter and 42.3" long.

|

|

| Type N (NARA, AEE) | |

The Type N, a nine-cylinder monosoupape rotary developed during the WWI, had a 115 mm (4.528") bore, 170 mm (6.693") stroke, 15.832 l (969.8 in³) displacement and 5.45:1 compression ratio. It was rated 165 hp at 1,350 rpm and it delivered 170 hp. It was equipped with two magnetos, and weighed 290 lb, or 1.76 lb/hp.

An eighteen-cylinder doubled Type N displacing 31.784 l (1939.6 in³), was rated at 300 from a 600 lb weight. Its diameter was 37" and its length 53.2"

An 11-cylinder monosoupape engine using Type N cylinders and displacing 19.423 l (1,185.3 in³) was rated 190 hp at 1,300 rpm from a 380 lb weight.

Gnome experimented with a 20-cylinder air-cooled rotary with four rows of five cylinders. The bore was 140 mm (5.512"), stroke was 170mm (6.693") and displacement was 53.389 l (3,258.0 in³). Output was 600 hp at 1,400 rpm and 800 hp at 1,700 rpm. Diameter was 42.3" and length was 59.1".

|

| Gnome-Rhone Images |

Gnome-Rhone

Société des Moteurs Gnome-Rhone, headquartered in Paris, France, continued building the 80 hp and 110-hp LeRhone rotary engines for a time after WWI. However, Gnome-Rhone was primarily involved in license-building large air-cooled radials, starting with Jupiter and Titan licenses from the Bristol Aeroplane Co., Ltd. in 1922. These engines were sold to the French Government and other European customers. Later Gnome-Rhone designs were licensed to Walter in Czechoslovakia, I.M.A. Rakovitza in Yugoslavia, I.A.R. in Rumania, O.G.M.A. in Portugal, Alvis in England, Piaggio and Isotta-Fraschini in Italy, Nakajima in Japan, and to the Russian Government. Gnome-Rhone converted some A.B.C. motorcycle engines for light-plane installation during 1924. These engines displaced 24.75 in³, delivered 10 hp at 4,000 rpm and weighed 40 lb.

The Gnome-Rhone Jupiter, developed from the Bristol Jupiter, was produced originally in four models. Its bore was 146 mm (5.748"), its stroke 190 mm (7.480"), and its displacement 28.628 l (1,747.0 in³). Except for the cast-aluminum crankcase, the Gnome-Rhone Jupiter was essentially identical to the British design. A direct drive version with a 5.3:1 compression ratio and weighing 737 lb produced 540 hp at 2,000 rpm. With a 6.5:1 compression ratio it produced 580 hp at 2,000 rpm. Weighing 836 lb and with a 2:1 Farman reduction gear, the 5.3:1 compression ratio version produced 510 hp at 2,000 rpm, and with a 6.5:1 compression ratio produced 550 hp at 2,000 rpm.

The Jupiter 9Adv, a direct-drive model with a 5.3:1 compression ratio developed 420 hp at 1,750 rpm and weighed 807 lb.

The Jupiter VI 9Ac, a direct-drive model with a 6.7:1 compression ratio, was rated 480 hp at 2,000 rpm and weighed 827 lb.

The JupiterVII 9Asb, a direct-drive model with a 5.3:1 compression ratio, was rated 420 hp at 2,000 rpm and weighed 869 lb.

The Mercure V, a geared engine patterned after the Bristol Mercury that weighed 946 lb, produced 475 – 555 hp at 2,020 rpm.

The Titan 5BC was an air-cooled direct-drive five-cylinder radial displacing 870.5 in³ following the Bristol Titan design. With a 5.3:1 compression ratio it developed 240 hp at 1.800 rpm. Dry weight was 561 lb.

In 1928, supercharged models similar to the British designs were added. In 1929, Gnome-Rhone started the air-cooled Series K radial engine design using a different cylinder construction. The 5KC engine was completed and began tests in 1930. During 1931 and 1932, Gnome-Rhone introduced several KC and Kb types, all with a 146 mm (5.748") bore, a 165 mm (6.496") stroke and 5.5:1 compression ratio.

The five-cylinder 5KC, with a 13.812 l (842.9 in³) displacement developed 240 – 270 hp at 2,000 rpm and weighed 500 lb. Its diameter was 47.24" and its length 38.97".

The seven-cylinder 7KC300 – 360 hp at 2,000 rpm, weighed 585 lb, had a 48.42" diameter and 39.25" length.

The seven-cylinder 7KCs, with a 19.336 l (1,180.0 in³) displacement delivered 280 – 345 hp at 2,000 rpm and weighed 610 lb.

The nine-cylinder, geared 9KCr, with a 24.861 l (1,517.1 in³) displacement produced 500 – 550 hp at 2,250 rpm, weighed 840 lb and had a 51.18".

The 9Kbrs corresponded to the 9KCr except that it weighed 850 lb, produced 450 hp at 2,200 rpm and 520 hp at 2,300 rpm.

The 14Kb2 was a geared, air-cooled, two-row fourteen-cylinder radial displacing 38.673 l (2,360.0 in³) and producing 700 – 800 hp at 2,030 rpm. Weight was 1,155 lb, diameter was 50.39" and length was 61.02".

The 14 Kbrs was similar to the 14Kb2 except that it weighed 1,183 lb., and delivered 625 – 730 hp at 2000 rpm. A later version of this engine was known as the Mistral Major and delivered 750 – 810 hp at sea level.

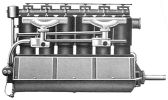

Green

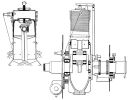

For several years prior to WWI, the Green Engine Co. Ltd. of London built water-cooled aircraft engines known for being among the most reliable produced in England. Green cylinders were cast from steel and fitted with copper water jackets made tight by rubber rings. Long bolts through the crankcase secured the cylinders and the crankshaft bearing caps. A seven-bearing camshaft, driven from the crankshaft by a vertical shaft and skew bevel gears, in conjunction with rocker arms, were enclosed above the cylinder head. The valves stood vertically in the cylinder head and seated on removable cages. The crankshaft had plain bearings on either side of each crank throw and a front-mounted double-row ball bearing took the propeller thrust. A gear pump circulated oil to the bearings at about 20 psi and a gear pump with bronze wheels circulated the cooling water. Magnetos furnished ignition for all Green engines.

The C-4, a vertical four with a 105 mm (4.134") bore, 120 mm (4.724") stroke and a 4.156 l (253.6 in³) displacement produced 32 hp at 1,200 rpm. Fuel consumption was 0.503 lb/hp/hr and the dry weight was 160 lb, or 5 lb/hp. The flywheel weighed 23.5 lb additional.

The D-4, a vertical four with a 140 mm (5.512") bore, 146 mm (5.748") stroke and a 8.990 l (548.6 in³) displacement delivered 60 hp at 1,100 rpm. Fuel consumption was 0.059 lb/hp/hr and oil consumption 0.011 lb/hp/hr. Weight, including a 37-pound flywheel, was 260 lb.

The E-6, a vertical six with a 140 mm (5.512") bore, 152 mm (5.984") stroke and 14.039 l (856.7 in³) displacement, was rated 100 hp but developed 120 hp at 1,250 rpm. Fuel consumption was 0.48 lb/hp/hr. Dry weight was 447 lb including a 37 lb flywheel.

A vertical eight with a 116 mm (4.567") bore, 140 mm (5.512") stroke and a 11.837 l (722.3 in³) displacement was rated 82 hp at 1,100 rpm.

Green built water-cooled six, twelve, and eighteen-cylinder engines, rated 150, 300 and 450 hp at 1,200 rpm, around 142 mm (5.591") bores and 178 mm (7.008") strokes. The vertical six displaced 16.914 l (1,032.1 in³). The 60° V-12 displaced 33.827 l (2,064.3 in³). The 40° W-18, with three rows of six cylinders, displaced 50.741 l (3,096.4 in³).

|

|

|

|

|

| E-6 (AEE) | V-12 (AEE) | W-18 (AEE) | ||

The Type 64, a later water-cooled vertical four with a 106 mm (4.173") bore, 120 mm (4.723") stroke, a 4.236 l (258.5 in³) displacement and a 5.6:1 compression ratio was rated 35 hp at 1,250 rpm but developed 40 hp at 1,300 rpm. Fuel consumption was 0.54 lb/hp/hr, oil consumption 0.112 lb/hp/hr, and dry weight 185 lb. One Watford E-4 magneto provided ignition and a Zenith 36ABC carburetor supplied the mixture.

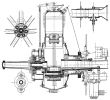

Gyro

The Gyro Motor Company of Washington, DC, under the direction of Emile Berliner, designed and built an early successful air-cooled rotary. This engine, along with the Adams-Farwell rotary engines, was used in the Berliner helicopter experiments.

The Old Gyro, was an air-cooled seven-cylinder rotary engine with a 4.312" (109.54 mm) bore, 4.750" (120.65 mm) stroke and 485.7 in³ (7.950 l) displacement rated 50 hp at 1,500 rpm. It weighed 160 lb, or 3.2 lb/hp. Fuel consumption was 0.72 lb/hp/hr and oil consumption 0.17 lb/hp/hr. Each cylinder's exhaust valve was located in the cylinder head and actuated by a push rod and rocker arm. The poppet intake valve, located in the piston, was operated by a lever that contacted a second lever pivoted on the connecting rod and moved due to centrifugal force. Some Old Gyro engine cylinders were fitted with 36 vertical Moore cooling tubes, but ordinarily the fins were cut as a continuous screw thread. The steel cylinders were clamped between the crankcase halves. The connecting rods had H section shanks. Ball bearings were used throughout and a double-row ball bearing at the propeller end carried the thrust.

In 1914, the Gyro Motor Company began marketing an air-cooled Duplex model that featured a two-row duplex cam (from which the name was derived). The aft cam operated the exhaust valve via a push rod and rocker arm; the forward cam operated a slide valve intake mechanism attached to the cylinder exterior about two inches above the piston when it was at bottom center. Cylinder ports communicated with inlet gas conduits via the slide valve, which also served as an auxiliary exhaust port. All Duplex models featured a 4.500" (114.3 mm) bore and 6.000" (152.4 mm) stroke, resulting in a 95.43 in³ (1.564 l) displacement per cylinder.

The Model J five-cylinder Duplex displaced 477.13 in³ (7.819 l) and was rated 50 hp at 1,270 rpm and weighed 170 lb, or 3.4 lb/hp.

The Model K seven-cylinder Duplex displaced 667.98 in³ (10.848 l) and was rated 90 hp at 1,250 rpm and weighed 215 lb, or 2.4 lb/hp.

The Model L nine-cylinder Duplex displaced 858.83 in³ and was rated 110 hp at 1,200 rpm and weighed 270 lb, or 2.45 lb/hp. Fuel consumption was 0.79 lb/hp/hr and oil consumption was 0.16 lb/hp/hr.

|

|

|

|

|

| Old Gyro | Duplex | Model K, Valve Mechamism | Model L | |

References

Angle, Glenn D, ed. Aerosphere 1939 (New York, New York: Aircraft Publications, 1940).

Anble, Glenn D, ed. Airplane Engine Encyclopedia (Dayton, Ohio: Otterbein Press, 1921).

Image Sources: A39 = Aerosphere 1939; AEE = Airplane Engine Encyclopedia; Flt = Flight Magazine; NARA = U.S. National Archives and Records Administration; UKNA = United Kingdom National Archives.