Selected Early Engines

Darracq, DeDion, Detroit Aero,

Dodge, Duesenberg, Duthiel-Chalmers

Compiled by Kimble D. McCutcheon

Published 6 May 2022; Revised 8 May 2022

|

| Darracq Two-Cylinder (AEE) |

Darracq

Darracq water-cooled horizontal and vertical engines first appeared in France about 1909. The smaller of these, a horizontally-opposed two-cylinder, had a 130 mm (5.128") bore, 120 mm (4.724") stroke, and 3.186 l (194.4 in³) displacement was rated 24 hp at 1,500 rpm and weighed 121 lb, or 5 lb/hp. It powered the original Demoiselle, the first light airplane built by pioneer aviator, Alberto Santos-Dumont.

The cylinders were machined from solid steel billets to which copper water jackets were hard-soldered. Valves in the cylinder head were operated by push rods and rocker arms, and holes in the lower cylinder walls served as auxiliary exhaust ports. A magneto supplied ignition and a pump sprayed lubricating oil into the crankcase.

A water-cooled horizontally-opposed four with a 130 mm (5.128") bore, 120 mm (4.724") stroke, and 6.371 l (388.8 in³) displacement, was rated 48 hp at 1,500 rpm and weighed 242 lb, or 5 lb/hp.

A Darracq water-cooled vertical four with a 120 mm (4.724") bore, 140 mm (5.512") stroke, and 6.333 l (388.8 in³ ) displacement produced 43 hp at 1,500 rpm weighed 374 lb, or 8.7 lb/hp.

A larger water-cooled vertical four with a 170 mm (6.693") bore, 140 mm (5.512") stroke, and 12.711 l (775.7 in³ ) displacement produced 84 hp at 1,200 rpm and weighed 550 lb, or 6.55 lb/hp.

For a time the Societe Anonyme Darracq of Suresnes, France held manufacturing rights for English Sunbeam Motor Car Co. Coatalen engines, including the 100 hp Dyak, 300 hp Manitou and 420 hp Matabele. These almost identical with the original Sunbeam designs and were generally referred to as Talbot or Talbot-Darracq engines.

|

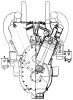

| De Dion 80 hp V-8 (AEE) |

De Dion

The French De Dion-Bouton Company introduced an air-cooled 90° V-8 about 1915 and a water-cooled V-8 about two years later. During WWI, De Dion experimented with an X-16. The first De Dion air-cooled 90° V-8, with its 100 mm (3.937") bore, 120 mm (4-724") stroke, and 7.54 l (460.9 in³) displacement produced 80 hp at 1,700 rpm and weighed 465 lb, or 5.8 lb/hp. The propeller rotated at 0.5 crankshaft speed, its shaft driving the camshaft that was located in the Vee. A forced-draft cooling system with a fan, driven from crankshaft front, forced air around the cylinders through an aluminum housing fitting over the Vee. Fuel consumption was0.50 lb/hp. The oil sump capacity allowed seven hours operation at full speed. Ball bearings were used at both crankshaft ends and plain bearings were used at the three intermediate bearing locations. Fork-and-blade connecting rods were employed. Individual F-head cylinders were tied to the crankcase by long bolts extending to a bridge piece over the head. The valves were in pockets toward the Vee interior. Inlet valves were operated directly by tappets and exhaust valve just above by push rods and rockers.

A water-cooled V-8 with a 125 mm (4.921") bore, 150 mm (5.906") stroke and 14.726 l (898.6 in³) displacement was rated 150 hp at 1,600 rpm and weighed 968 lb, or 6.45 lb/hp.

An experimental water-cooled X-16 with four banks of four cylinders each had a 170 mm (6.693") bore, 190 mm (7.480") stroke, 69.002 l (4,210.8 in³) displacement produced 800 hp at 1,400 rpm and weighed about 1,900 lb. It had two inlet and two exhaust valves per cylinder.

|

| Detroit Aero 25 hp (AEE) |

Detroit Aero

Detroit Aero Engines were designed and built by Fred Weinberg of Detroit, Michigan during 1910 and 1911. More than 1,000 of these engines were sold to amateur aviators throughout the U.S. during that period. The engine was an air-cooled horizontally-opposed two-cylinder rated 25 – 30 hp at 1,500 rpm. The bore was 5.5", the stroke 5.0" and the displacement 237.6 in³. The valves were located in the cylinder head and operated through push rods and rockers. A magneto furnished ignition.

|

| Dodge Victory (AEE) |

Dodge

During 1918, the Dodge Tool Company of Grinnell, Iowa built an air-cooled six-cylinder radial known as the Victory. With a 5.000" bore, 6.000" stroke and 706.9 in³ displacement, it produced 125 hp, and weighed 394 lb. The steel cylinders were held in place by clamping rings. Two vertical exhaust valves were located forward and one vertical inlet rearward in the cylinder head. Plain bearings were used throughout. A two-throw crankshaft had two master/slave connecting rod assemblies. A Bosch two-spark magneto furnished dual ignition.

|

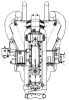

| Duesenberg 125 hp (AEE) |

Duesenberg

Fred Duesenberg, a well-known American internal combustion engine designer, organized the Duesenberg Motors Corporation of Elizabeth, New Jersey in 1917. Various Duesenberg marine, automobile, and airplane engines had previously been built in a small Rockford, Iowa shop.

The Model A-44, a water-cooled vertical four was Duesenberg's first aircraft engine. With a 4.375" bore, 6.000" stroke, and 360.8 in³ displacement it produced 70 hp at 1,500 rpm and weighed 365 lb. The valves were set horizontally in the cylinder head, a feature common to several Duesenberg designs.

A larger water-cooled in-line four with a 4.75" bore, 7.00" stroke and 496.1 in³ displacement was rated 125 hp at 2,100 rpm, but produced over 140 hp. The engine was available with either a direct or 51:33 geared propeller drive. The direct-drive engine delivered 100 hp at 1,400 rpm and weighed 436 lb; the geared model weighed 509 lb. Steel cylinders were cast en bloc and aluminum plates attached by screws at the ends and sides served as water jacket covers. Horizontally opposed inlet and exhaust valves were used with the inlet valve seating in a cage that, when removed, provided an opening for exhaust valve removal. The two inlet and two exhaust valves in each cylinder had 1.72" clear diameters and were operated by long rocker arms from a camshaft on either crankcase side. The rocker arms were enclosed by an oil-tight cover. The four-throw three-main-bearing crankshaft used tubular-shank connecting rods with four-bolt caps. The aluminum pistons used one three-piece ring. A Bosch magneto provided dual ignition and a gear-type oil pump maintained pressure at 25 psi.

|

| Duesenberg Model V-12 (AEE) |

The Model V-12, a water-cooled upright V-12 with a 4.875" bore, 7.000" stroke and 1,567.9 in³ displacement produced 300 hp at 1,400 rpm. Its cylinders were cast in pairs from iron and used aluminum plates to cover the water jackets. Side-by-side inlet and exhaust valves were set at right angles to the cylinder axis and were operated by long rocker arms from a camshaft in the Vee. A continuous inlet manifold over the Vee accommodated one or two carburetors. The six-throw four-main-bearing crankshaft used side-by-side tapered tubular-shank connecting rods with four-bolt caps, resulting in staggered opposite cylinder banks. Aluminum alloy pistons were fitted with one three-piece ring. A double centrifugal pump circulated water to each bank of cylinders independently. Two twelve-cylinder magnetos furnished dual ignition. An electric starter with 25:1 gearing, and a chain-driven electric generator running at 1.5 times crankshaft speed were options.

The Model H was a water-cooled 45° V-16 with a 6.0" bore, 7.5" stroke and 3,392.9 in³ displacement designed and built during WWI. It was rated 800 hp at 1,800 rpm and was available with either direct or 33:25 geared propeller drive. The direct-drive model weighed 1,390 lb and the geared model weighed 1,575 lb. Steel cylinder heads had screwed-in and welded steel barrels and welded-on sheet-steel water jackets. The usual Duesenberg valve mechanism was used, but with shorter rocker arms as the single camshaft was mounted higher in the Vee. Inlet and exhaust valves were on the inside of the Vee and could be removed after unscrewing plugs on the opposite side of the cylinder. Both valves had 30° seats. The single inlet valve had a 2.75" clear diameter and a 0.5625" lift. The two exhaust valves had 2.00" clear diameters and 0.5" lift. The eight-throw crankshaft had two single-plane four-throw elements at opposite ends and at right angles to one another. It ran on four plain bearings and one ball hearing. The fork-and-blade connecting rods had tubular shanks. The aluminum pistons were ribbed inside, and each was fitted with one three-piece ring. Four Miller carburetors, located at the outside, furnished the mixture. A triple gear-type combination pressure and scavenge pump, located in the oil pan fed high-pressure oil to the crankshaft and connecting-rod bearings. A regulating valve then reduced the pressure to the cylinders, camshaft and rocker arms. A double-outlet centrifugal pump located aft and under the engine circulated cooling water. Either battery or magneto ignition was available as an option. The engine was 88.750" long, 32.000" wide and 38.875" long.

|

|

|

|

| Front | Front/Section | Left | Aft |

Please see this excellent Duesenberg article by William Pearce

|

| Duthiel-Chalmers 20 hp in Demoiselle (AEE) |

Duthiel-Chalmers

Duthiel-Chalmers produced early French horizontally-opposed engines, starting with a 20-hp air-cooled two-cylinder that was used in one of Alberto Santos-Dumont's Demoiselles; all later engines were water cooled.

A horizontal two-cylinder with a 128 mm (5.039") stroke, 130 mm (5.118") stroke and 3.346 l (204.2 in³) produced 24 hp at 1,200 rpm and weighed 132 lb, or 5.5 lb/hp. Mechanically operated cylindrical sleeve valves were located in the cylinder head. The cylinders were secured by long studs passing through clamps above the head. The water outlet and the spark plugs were located at the cylinder tops, and the water inlet underneath. The crankshaft was fitted with a wire-spoked flywheel, and the pistons were lubricated by special oil feeds connected to the cylinder.

Another horizontally-opposed two-cylinder engine with a 110 mm (4.331") bore, 300 mm (11.881") stroke and 5.702 l (348.0 in³) displacement developed 37.5 hp at 1,000 rpm and weighed 200 lb, or 5.9 lb/hp.

A horizontally-opposed three-cylinder with a 110 mm (4.331") bore, 300 mm (11.881") stroke and 8.553 l (521.9 in³) displacement produced 56.5 hp at 1,000 rpm and weighed h 396 lb, or 7 lb/hp.

A horizontally-opposed four-cylinder with a 110 mm (4.331") bore, 300 mm (11.881") stroke and 11.404 l (695.9 in³) displacement was rated 75 hp at 1,000 rpm and weighed 528 lb, or 7 lb/hp.

Another horizontally-opposed four-cylinder with a 160 mm (6.299") bore, 140 mm (5.112") stroke and 11.259 l (687.1 in³) displacement developed 100 hp at 1,000 rpm and weighed 638 lb, or 6.38 lb/hp.

A horizontally-opposed four-cylinder with a 125 mm (4.921") bore, 300 mm (11.811") stroke and 14.726 (898.6 in³) displacement was rated 97 hp at 1,000 rpm and weighed 792 lb, or 8.2 lb/hp.

A horizontally-opposed six-cylinder with a 128 mm (5.039") bore, 130 mm (5.118") stroke and 10.037 l (612,5 in³) displacement produced 72.5 hp at 1,200 rpm and weighed 385 lb, or 5.3 lb/hp.

Duthiel-Chalmers built a horizontally-opposed engine series with two, four and six cylinders all with 125 mm (4.921") bores, 120 mm (4.724") strokes and 1.473 l (89.9 in³) single-cylinder displacements. These engines featured two spark plugs located within tapered valves that allowed spark plug changes while the engine ran. An interesting feature of these engines was the two spark plugs located in a valve. Either of the spark plugs could be removed while the engine was running by turning the tapered valve housing the spark plug.

| Cylinders | Displacement l (in³) | Rating hp | Weight lb | lb/hp |

|---|---|---|---|---|

| 2 | 2.945 (179.7) | 20 | 165 | 8.25 |

| 4 | 5.890 (359.4) | 40 | 264 | 6.60 |

| 6 | 8.836 (539.2) | 60 | 374 | 6.23 |

References

Angle, Glenn D, ed. Aerosphere 1939 (New York, New York: Aircraft Publications, 1940).

Anble, Glenn D, ed. Airplane Engine Encyclopedia (Dayton, Ohio: Otterbein Press, 1921).

Image Sources: A39 = Aerosphere 1939; AEE = Airplane Engine Encyclopedia; Flt = Flight Magazine; NARA = U.S. National Archives and Records Administration; UKNA = United Kingdom National Archives.