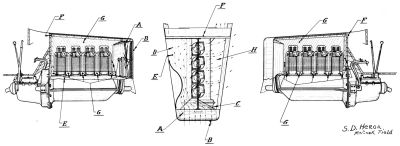

Sam Heron's Air-Cooled Inline Motorcar Engine Concept (NARA)

A Brief Outline of Aviation Engine History

by Robert Insley

Compiled by Kimble D. McCutcheon

Published 11 Nov 2023

The problem of flying has always been the problem of propulsion. Archytas in 400 BC made a wooden pigeon which "flew by means of mechanical powers and an Aura Spirit" but "when it fell to the ground could not raise itself again". And a monk named Elmerus flew a furlong from a tower in Spain. But man was eventually forced to the admission that his physical construction was vastly different from the bird's and that he could not hope by simply flapping his wings to reproduce the birds flight. So he was driven to the search for mechanical motive power and the flight of the airplane awaited its discovery.

The story of the aviation engine is the story of the internal combustion engine. And its true genesis, therefore, lies well back in history. In Asia sometime between the sixth and thirteenth centuries the conception of the internal combustion engine probably occurred, and the primitive cannon which Genghis Man's Chinese army used was one of its earliest representatives. The effectiveness of the device as a weapon was enormous largely because of its terrifying roar and appalling clouds of smoke. But there its utility ended and for several hundred years there appears to have been no imagination agile enough to recognize in it the elements of a useful power plant. It occurred to no one that the piston might be used repeatedly or that the pressure created by the explosion of the powder might be captured and directed to-useful purposes. And even when Abbe Hautefeuille in 1678 contrived to use the powder cylinder to, raise water the positive pressure in the cylinder was disregarded. For Abbe Hautefeuille utilized the partial vacuum in the cylinder paused by cooling and contraction of the gases after explosion and relied upon atmospheric pressure to force the water into the cylinder. And the same principle was employed by Huyghens several years later. But Huyghens substituted a piston for the direct water seal in the cylinder and prevented return of air to the cylinder by the use of a flap exhaust valve of leather.

These vacuum engines, however, appear to have been difficult to seal and for the most part rather impotent and they struggled along for ten years without any considerable success. By that time powder and coal gas engine experiments had become common in Europe and Americans were hurrying to gain ground. In 1791 John Barber produced in England a primitive gas turbine burning coal gas and directing the escaping gas against a paddle wheel and three years later in America Robert Street with a turpentine vapor engine began to utilize the positive pressure of combustion in the cylinder to drive the piston. With his engine he operated a water pump connected through a walking beam to the power piston. He produced his explosive mixture by passing the intake air over a turpentine soaked sponge and ignited the charge with a flame at a cylinder port. Lebon in 1801 substituted an electric spark for the flame ignition and made his engine double-acting, applying pressures at both sides of the piston. Lebon's unfortunate death occurred, however, before he had well initiated what promised to be an enormous contribution to engine development.

But all these attempts were thoroughly experimental. None of the engines was produced commercially with any success until the double-acting, slide valve engine of Lenoir appeared in 1860. Lenoir's engine was not, at all radical - simply a carefully designed and carefully constructed engine operating on the then-conventional two-stroke cycle, but it was mechanically vastly superior to the earlier engines and achieved for a time a considerable popularity. Otto and Langen were at the same time contriving an engine utilizing the four-stroke cycle devised by Beau de Rochas and in 1866 produced commercially an engine employing that principle. It was a vertical free-piston engine delivering power through a rack and ratchets and therefore was not mechanically a complete success. It was, however, an enormous improvement over its predecessors both in mechanical behavior and in economy of operation. Its fuel consumption was somewhat less than half that of Lenoir a engine. In 1878 it was displaced, however, by its direct offspring, the celebrated Otto engine, which has achieved prodigious commercial success and has been retained to a large extent to the present in its construction. The Otto engine operated also on the four-stroke cycle but employed a inline cylinder; a crank and connecting rod replaced the rack and ratchet.

With the successful commercial production of internal combustion engines the appearance of the motor car was a natural sequence. The utility of the internal combustion engine had been demonstrated and its employment as motive power for a vehicle established a definite market. Its evolution from that point was simple and rapid. Another cylinder was added and the very popular two cylinder inline opposed engine resulted. The demand for increased smoothness and reduced weight, however, brought forth the four cylinder vertical engine, the six cylinder vertical, the eight cylinder Vee type, the twelve cylinder Vee and eventually the eight cylinder vertical and even the sixteen cylinder vertical.

In the midst of the motor car engine development appeared the need for similar engines for aircraft. Experiments with gliders had been successful and the solution of the problem of flight with heavier than air machines appeared to depend on the provision of suitable motive power. Relatively little attention had been given the matter of weight reduction in motor car engines. Naturally the enormous weights of the stationary engines, frequently exceeding 100 pounds per horsepower, had been out of the question for motor car engines, and rather drastic reductions had been made there. But when weights of about 15 pounds per horsepower had been reached it was considered useless to attempt further radical reductions. The airplane requirements of minimum weight with maximum reliability, therefore, appeared to compel sweeping changes in engine construction. In addition the adaptation of engines for flight introduced operating conditions rarely encountered in motor car operation. The airplane engine would be called upon to operate almost wholly at full throttle whereas in automobile service such circumstances were rare. The airplane engine would be expected to behave nicely in extreme tilts rarely occurring in motor car service and in maneuvers which an automobile could never imitate, and, though it was not given much serious thought at the time, the airplane engine would be required to undergo in a single trip rapid extremes of temperature and altitude. So it became apparent that the new transportation would require an entirely new motive power similar in operation perhaps to the existing engines but vastly refined in detail, improved in performance and mercilessly reduced in weight.

Steam engines and electric motors were readily eliminated because of their prohibitive weights, although both had been used with fair success in the propulsion of dirigibles. Maxim indeed had conducted rather successful experiments with an airplane propelled by a steam engine. The inevitable obstacle presented by the steam engine of requiring the boiler and water besides the fuel, however, indicated the internal combustion engine as the more likely form of motive power. Santos Dumont and the Lebaudy brothers used ordinary automobile engines in their airships and, although Daimler rapidly developed very satisfactory light weight automobile engines, the Wright brothers and Professor Langley, when undertaking self-propelled airplane a experiments, found available no motive power suitable for their purposes and were forced to contrive their own engines. Accordingly there appeared shortly after 1900 two very much refined internal combustion engines, the four cylinder horizontal inline engine of the Wright brothers, conspicuous because it was used in the first successful airplane flight and the five cylinder radial engine designed for Professor Langley by Charles M. Manly - even more noteworthy than Wright's engine because of its singularly advanced design.

|

|

|

| 1903 Engine, Model B, Six-Cylinder (Frank Monger, NARA) | ||

The Wright brothers' first engine was a simple, thoroughly successful, four cylinder inline engine. Its bore was 4.375", its stroke 4.000" and its piston displacement 240.5 in³. It was rated at 12-16 hp at 1,200 rpm and weighed approximately 180 pounds. In construction it exhibited some rather bold departure from conventional motor car engine design. The cylinders ware of cast iron with sheet aluminum water jackets. The crankcase was cast of aluminum alloy with the oil sump in the case, Measured fuel injection into the manifold was explored in place of the carburetor and, for the sake of simplicity and lightness, automatic intake valves were used, although that type was already considered obsolete in automobile engine construction. Ignition was furnished by a high tension magneto. The crankshaft was machined from a solid billet of steel and provided with a flywheel. The two propellers were driven by chains from sprockets forward of the flywheel. The low weight per horsepower of the engine, about half that of contemporary automobile engines, appears to have exacted no sacrifice in reliability, for the engine was used repeatedly by the Wright brothers in flight and similar engines with only detail changes were flown satisfactorily in both Europe and America, The engine was freely copied by designers of both continents for years. [Note: the article originally specified the 1903 Wright engine as a vertical (meaning inline) engine producing 30 – 35 hp; those errors are here corrected.]

|

|

| Manly Engine The large wheels damped propeller drive shaft torsionalvibration. (NARA) |

|

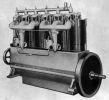

About coincident with the development of the Wright brothers' engine, Charles M. Manly was designing and having constructed for Professor Langley's experiments a five-cylinder, water-cooled, fixed-radial engine with a 5.000" bore, 5.500" stroke and 540 in³ piston displacement. Its weight was 150 pounds and its power 52.4 hp. Its specific weight, therefore, was 2.86 pounds per horsepower, somewhat less than that of many modern aviation engines. The cylinders of Manly engine were L-head type, built of sheet steel with pressed-in cast iron liners and sheet steel water jackets welded on. Like those of the Wright engine the intake valves were automatic and the exhaust valves positively actuated. The connecting rods were slipper type with tubular section except the master rod, which was solid. High tension battery ignition was used. Manly's engine, inasmuch as its specific weight was less than 3 pounds per horsepower at so early a stage in aviation engine development and at a crankshaft speed of less than 1000 rpm was truly a remarkable achievement and worthy of infinitely more consideration than it has been awarded.

|

|

| Air-Cooled V-8, Water-Cooled OX-5 V-8 (NARA) | |

But excellent as it was Manly's engine influenced the evolution of the flying engine but little in favor of the fixed radial type of engine. The fact that the first successful flight was made with the inline engine and that automobile engine development was following similar lines served to overshadow for a time the advantages of the radial construction. And the demands for increased power and reduced specific weight resulted in the addition of cylinders to the four cylinder vertical type and the early appearance of the eight cylinder Vee type engine. The Wright brothers added two cylinders to their engine and reduced its specific weight to 4.6 pounds per hp and shortly afterward used the same cylinder (with positive intake valve however) on an eight cylinder Vee type engine with a still lower weight-horsepower ratio. Curtiss, who for some time had been developing motor cycle engines, produced a four cylinder vertical air-cooled airplane engine but almost immediately substituted for it an eight cylinder Vee type air-cooled engine and shortly thereafter replaced that with an eight cylinder water-cooled engine, which in its general construction he retained for a number of years. The celebrated Curtiss OX engine produced in large quantities for training airplanes during the war with Germany was an immediate outgrowth from that engine.

|

| Dutheil-Chalmers Twin (NARA) |

Abroad the horizontal two cylinder opposed engine played a more important part in early aviation than it did in this country, and a considerable number of the pioneer flights in Europe were accomplished with such engines. The Darracq 24 hp water-cooled engine with a weight of about 5 pounds per horsepower and the Dutheil-Chalmers 20hp air-cooled engine that Santos-Dumont used in his Demoiselle were the most successful early representatives of the type on the Continent. They were followed by larger engines of that construction by the same makers and by similar engines of Clement-Bayard in France, Falons and Beuse in Germany and Alvaston in England.

The early airplane engine development was forwarded in Europe largely by Daimler whose attention for a number of years had been successfully directed toward the perfection of the automobile engine, by Louis Renault, an automobile manufacturer of Billancourt, by Levasseur who built the Antoinette engine, and in England by Green. The two cylinder vertical Daimler engine of 1897 was the real forerunner of the later highly successful Daimler and Mercedes-Daimler engines. The first Daimler engine designed for aviation service, however, was a four cylinder vertical engine of 85 horsepower with overhead valves and cylinders in pairs. Beginning with a four cylinder vertical engine of power and dimensions much similar to those of the first Wright engine, Renault rapidly produced several four cylinder vertical and eight cylinder Vee type engines with both air and water cooling. The most successful of his early engines, however, was the air-cooled eight cylinder engine used in the eight-hour flight of Tabuteau in 1910. The Antoinette engines were built in eight, sixteen and thirty-two cylinder types with fuel injection into individual ports and with cooling effected by the evaporation of water in the jackets. The steam was condensed in the radiator. The Green engine development in England was initiated with a four cylinder vertical engine of piston displacement approximately that of the first Wright engine, developing about 40 hp at 1,200 rpm. A similar engine of 60 hp was produced shortly afterward but was later displaced by a six cylinder vertical engine of 120 hp at 1,250 rpm.

|

| Anzani 20-Cylinder (NARA) |

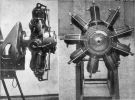

Fixed radial engines rare given their early impetus largely from the Continent. After Manly's engine for Professor Langley's Aerodrome little promising radial engine development occurred in America for several years. Abroad, however, the Anzani engine came into early prominence in Bleriot's flights and a 25 hp three-cylinder air-cooled engine of that make was the first to cross the English Channel. The Anzani production developed rapidly and included in a relatively short time radial engines of three, five, six, seven, nine, ten and twenty cylinders with both air and water cooling. The fixed radial type was represented later by the Salmson water-cooled engine and in 1914 six sizes ranging from the 90 hp 7 cylinder engine to an 18 cylinder 600 hp engine were in production.

|

| Adams-Farwell (NARA) |

The first successful rotary radial engine development occurred in the United States, initiated by the Adams Company in the commercial construction of an engine originated by F.O. Farwell for automobile propulsion. And the principle was applied under the direction of Emile Berliner in 1907 to a horizontal rotary engine to be used in his helicopter.

The same type of engine (with cylinders in a vertical plane however), was soon constructed for airplanes and shortly afterward the Gnome engine of Laurent Seguin appeared in France, employing largely the construction successfully demonstrated in the performance of the five cylinder Adams-Farwell engine.

Mr. Berliner also fostered the design of the Gyro rotary engine, which employed a piston head intake valve operated by the oscillation of the connecting rod and with a mechanically operated exhaust valve in the cylinder head. That construction was subsequently modified by the substitution of a duplex port valve in the cylinder wall, uncovered by the piston and acting as either intake or exhaust valve under the control of an auxiliary piston valve.

|

| Gnome Monosoupape (NARA) |

The first successful European rotary engine to appear was the Gnome invented by Laurent Seguin, first represented by a 34 hp 5 cylinder air-cooled engine. A seven cylinder 60 hp engine of similar construction shortly displaced it and by 1913 eight different sizes were being produced with seven, nine, fourteen and eighteen cylinders and ranging in horsepower from 45 to 180. The famous Gnome Monosoupape with intake port uncovered by the piston and mechanically operated exhaust port, appeared in 1913 and played an important part in World War I. The LeRhone and Clerget were later European developments of the rotary type. Both were of conventional design and gained considerable prominence in military service. The windage loss, gyroscopic effect and high fuel and oil consumption of the rotary engines, however, appear to more than counterbalance the advantages of light weight and simplicity of operation and the rotary engine is being displaced to a large extent by the fixed radial type.

In general the specific weight of the airplane engine is dependent upon three qualities - the engine type (including the number of cylinders), the engine performance and the detail refinements of design. Manly's engine at the very beginning of aviation engines very positively demonstrated the virtues of the radial type engine in reduction of weight. Other considerations, however, chief among which was the parallel development of the automobile engine, favored the inline arrangement of cylinders and that engine type has since predominated by virtue, principally, of its priority.

But there are some points in favor of the conventional vertical or Vee type engine. It has in itself somewhat less head area than the radial engine of equal power and presents les wind resistance in flight. Its manifolding difficulties, at present, are less severe than those of the radial type and its inline construction permits the use of more rigid valve gear and consequently offers the possibility of higher rotational speeds than the radial type. There, however, seems to be the end of its superiorities.

The radial engine, while normally of greater frontal area than the inline engine, is considerably more compact longitudinally. Its crankshaft and crankcase are correspondingly reduced in weight and the very cylinder arrangement alone in the radial engine makes it possible to reduce the weight-horsepower ratio materially. The same advantages obtain in the use of the radial rotary engine but are largely counteracted by the windage loss of that type and the excessive fuel and oil consumption.

There remains another engine type which has not yet been considered but which appears to surpass both the radial and line engine in compactness and light weight. That is the "barrel" engine, arranged with cylinders parallel to the crankshaft and pistons communicating with the shaft through an inclined plate and bearing. Its construction offers the advantages of integral water jackets, greatly simplified valve gear and very compact arrangement of cylinders and crankshaft.

But whatever the cylinder arrangement adopted the engine weight is again seriously affected by the roans of cooling employed. Water cooling, like the inline engine, predominates chiefly because of priority of development. Th. air-cooled engines were early in the field, it is true, and were rather successfully built for low performance by Renault and Curtiss (and in radial form by several other manufacturers) but the manufacturers were easily frightened by the thermal and mechanical difficulties encountered and readily were persuaded to adopt water cooling even at the cost of the additional weight of cooling water and radiator. The air-cooled engine has been energetically advanced since the war, however, and already in the smaller radial engines, at least, appears to be very nearly the equal of the conventional water-cooled engine in performance and very definitely its superior in its possibilities of weight reduction. Its frontal area, moreover, when properly cowled, appears to be no more serious than that of the water-cooled engine and cooling system.

The method of selecting the most advantageous number of cylinders for a given power is still a matter of controversy. The answer lies with the purpose of the design and the engine speed to be attained. Early designees, following the Wrights' lead, favored for some time the four cylinder vertical engine. Its vibration, however, and the demand for high power soon ruled it out and six cylinders shortly became the minimum in vertical engines. As engine speeds increased and consequently the importance of keeping reciprocating weights small the number of cylinders rapidly mounted and the weight-power ratio was actually reduced because of the additional power made available by the increase in speed.

After the engine type has been established there remain but two methods of reducing its weight-power ratio, improvement in performance and reduction in weight; and there are, in general, two methods of accomplishing both of those purposes. Improvement in engine performance requires either an increase in output per revolution or an increase in the number of revolutions per minute. The first is a matter largely of cylinder charge and compression pressure. The early engines suffered seriously because of poor volumetric efficiency. The necessity of holding open the spring-loaded valve during intake, the long and poorly proportioned manifolds, the obstructions to the intake charge and the inaccurate valve timings considerably reduced intake and compression pressures so that the first Wright engine (of exceptionally high performance among contemporary internal combustion engines) showed at 1,200 rpm a bmep of only 98 psi in contrast with the pressures of about 140 psi obtained with the better engines in service today. The compression pressures were further limited by the low expansion ratio used. Very rapid progress has been made in bettering cylinder performance by intake passage improvements, better valve proportions and timing, increased compression ratio and improvement of combustion by multiple spark plugs and combustion chamber modifications.

The increase in rotational speed of the aviation engine was accomplished a little more slowly. Manly's engine was rum at 950 rpm and the first Wright engine at 1,200 rpm normal speed. With refinements in design, however, higher speeds became possible. The positively operated intake valve and modifications to the intake system permitted increases in speed without any appalling loss of volumetric efficiency. The overhead camshaft, improved balance, and greatly lightened reciprocating parts - made possible by the reduction in size and increase in number of cylinders, - still further simplified the problem until in present designs normal speeds of 2,000 rpm are not unusual and motor car engine development indicates the practicability of additional radical increases.

In actually reducing the weight of the engine without other modifications there are two paths open, redesign to employ modified or reduced members or the use of lighter materials. Both have been employed extensively in aviation engine development and together are responsible for at least half of the reduction of weight-power ratio represented in present day engines. Crankcases have been modified to increase rigidity and reduce material and have been cast of very light aluminum alloys. Crankshafts have been greatly increased in diameter and lightened by boring. Connecting rods have been altered in proportions for more uniform stress distribution and pistons have been considerably reduced in size and cast of very much lighter material. The built-up steel cylinders, although they now appear to be somewhat heavier than block construction with aluminum jackets have been retained frequently because of their advantages in quantity production. Very extensive use has been made of aluminum alloys in reducing the weight of lightly stressed rants. Pistons, crankcases, accessory bodies, plugs, carburetor bodies, gear housings and manifolds of aluminum or magnesium alloys are now expected and the use of improved steels has permitted weight reduction in more highly stressed parts.

The aviation engine at since 1900 has made enormous progress in weight reduction and undoubtedly still has far to go. The limit in engine speed has not been reached nor is there reason to believe that 140 psi bmep cannot to greatly exceeded. Aviation engine development is still in very active infancy and we may fairly expect in the next twenty years even more rapid and remarkable achievements than have occurred in the last twenty.

|

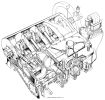

| The "Modern" Curtiss D-12 (NARA) |