Accidents Due to Water Injection Servicing Errors

by Carl Kuhns

Published 14 May 2023; Revised 25 Nov 2023

| Several notable accidents resulted from piston-powered aircraft being misfueled with Jet A. Modern fuel filler design has all but eliminated this. Another much less common issue arose from water injection systems being serviced by something other than water. Both piston engines and gas turbines depend on water injection to cool critical components during high-output operation. When water is replaced by something flammable, bad things happen. |

Introduction

Water injection is a system of injecting atomized distilled water into either a turbine or a reciprocating engine. Anti-detonation injection (ADI) reduces the temperature of the compressed charge and quells detonation in a reciprocating engine; it also allows the use of a leaner mixture, which further increases engine power. In a turbine engine thrust augmentation is the term applied to the water injection process. The standard mix for the water injection fluid is 50% distilled water, 50% either methyl or ethyl alcohol as an antifreeze. If the ambient temperature is high and all of the fluid will be exhausted on takeoff no antifreeze is needed. This was the case in the Viet Nam. The Republic F-105's Pratt & Whitney J75 injected 100% water and used afterburning (reheat) on takeoff.

During World War II, single engine fighters used ADI in combat situations when a burst of power was needed. After the war it was found that multi-engine transport aircraft could benefit from water injection. The use of water injection would decrease the take off distance and increase the rate of climb.

Accident #1

On June 12, 1957, a Flying Tiger Douglas DC-6A, N34953 powered by Pratt & Whitney Double Wasp CB-17 engines was scheduled to make a ferry flight to Dover, Delaware. Only five flight crew members and four Flying Tiger company passengers were on that flight departing from New York’s Idlewild Airport. A pre-takeoff engine run up showed that all pressures and temperatures were normal. A take off was made using 2,800 RPM, 59.5 inches of manifold pressure and ADI. Soon after breaking ground, a nearly simultaneous loss of power occurred on all four engines. A gear up landing was made on a sand bar in Jamaica Bay. There were only two minor injuries as a result of the DC-6A’s forced landing. The accident investigators obtained samples of the ADI fluid and gasoline from N34953. The gasoline was uncontaminated and of the correct octane rating.

The ADI fluid, instead of the 50/50 mix of water and methyl alcohol, contained ethylene glycol. Ethylene glycol is used to deice aircraft flying surfaces. The mechanic pointed out the drum that he used to fill the ADI cart. That drum’s lettering was dirty and blurred, but was labeled “ethylene glycol.”

|

|

| Flying Tigers DC-6A, N34953, on Jamaica Bay Sand Bar (Public Domain) | |

Accident #2

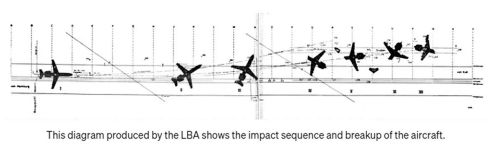

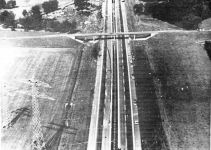

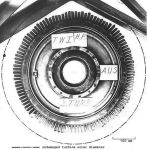

Paninternational Airline was a West German Airline that flew flights to holiday destinations. The airline’s fleet consisted of two Boeing 707s and Four BAC One-Elevens. On September 6, 1971, a BAC One-Eleven registration D-LAR was scheduled to fly from Hamburg, Germany to Málaga, Spain. Because the take off would be “hot and heavy,” the water injection thrust augmentation was used. The surface temperature was 17°C (63°F) and there was a full load of 115 passengers and six crew members. The pilots did not know that D-LAR’s water injection tank was partially filled with jet fuel. Since water and jet fuel do not mix, and water is heavier than jet fuel, the water settled at the bottom of the tank. This physical property allowed the thrust-augmentation to work properly just until the water was exhausted; thereafter the jet fuel was injected instead into the Rolls-Royce Spey engines.

When D-LAR reached 700 feet above ground level, both engines failed and D-LAR crashed into an autobahn overpass. The aircraft was destroyed and 22 people were killed. An examination after the crash revealed that the thrust augmentation system’s lines were full of 97% jet fuel. The origin of the jet fuel was a defueled Paninternational 707. A maintenance operation had required draining the 707's fuel. After an empty fuel truck was completely filled, the mechanics put the rest of the jet fuel into two un(LBA)eled 60-liter plastic drums. The drums with the jet fuel were moved to a storage area, which also held un(LBA)eled 60-liter plastic drums with demineralized water for the thrust augmentation systems. The D-LAR servicing crew unknowingly loaded the jet fuel instead of demineralized water.

|

|

|

| BAC One-Eleven (Wiki) | BAC D-LAR Flight Path (LBA) | BAC D-LAR Ground Path (LBA) |

|

|

| BAC D-LAR Touchdown Skid (LBA) |

BAC D-LAR High-Pressure Turbine (LB)) |

Conclusion

In both cases the water injection, normally intended to reduce engine temperatures, was replaced by other substances that actually increased temperatures, causing engine failures. We are interested in more examples of water-injection servicing failures that resulted in accidents. Please send details to the webmaster using the email link below.

Accident # 3: F-105 Thunderchief Water Mishap at Holloman AFB, New Mexico

In response to the author's request, Rich O'Brien has related a F-105 water servicing error that he witnessed.

The following incident that resulted in the near-destruction a USAF F-105 Thunderchief occurred while I was a refueling truck driver assigned to Petroleum, Oil, and Lubricants (POL) section, 49th Supply Squadron, at Holloman AFB, New Mexico (1975-77). During the winter of 1975/1976 (exact date uncertain) an F-105 from another base stopped at Holloman for fuel and water. To the best of my memory, the following is an accurate account of what happened.

Airman M was sent by our POL dispatcher to hook up to the demineralized water trailer in our parking area, tow it out to the F-105 and service the plane with water. It was winter and our dispatcher failed to inform M that the trailer was in the garage overnight to prevent the water in the pump from freezing. M went to the parking area where small tank trailers of a similar type were normally parked and failing to read the very clear marking on the side of the trailer, CONTAMINATED FUEL, M mistook it for the water trailer and attempted to hook up with his tow vehicle. He had difficulties with the tow coupling and called on the radio for his supervisor to come assist.

The supervisor, well aware of the call for demineralized water for the F-105, assisted with the hook up, also not noticing the large and clear CONTAMINATED FUEL markings on the trailer. The supervisor went back toward the POL building after assisting, but on his way, noticed M speeding through the POL parking lot, trailer in tow. The supervisor ran through the building, out the front door, and intercepted M’s truck pulling the contaminated fuel trailer toward the POL gate, where he ordered M to slow down ‑ still not noticing that M was pulling the wrong trailer.

M arrived at the transient aircraft parking area and the ground crew assisted with pumping contaminated fuel into the water tank at the rear of the F-105. As required, M wrote in by hand on the delivery form that the product was DEMINERALIZED WATER, after which M and the ground crew chief both signed a statement on the delivery form that they had visually confirmed the markings on the delivery container matched the product hand-written on the form. Neither airman actually bothered to look at the tank and amazingly, neither seemed to notice the odor of fuel fumes coming from the “water” either. This is worth noting because the nozzles for both the water trailer and the contaminated fuel trailer were of the identical “over-wing” type. When inserted into the large fill hole on the aircraft, the nozzle was squeezed open by hand when filling, resulting in fumes escaping the fill hole that would be difficult for the person operating the nozzle to ignore.

M finished servicing the aircraft, left the area, and parked the trailer back on its spot in the POL compound, unaware of his error until after the resulting runway drama took place. After a normal start-up and taxi to the end of the runway, the pilot got cleared for take-off, throttled up for the takeoff roll, and opened the "water" jets for thrust augmentation. But instead of water, the Pratt & Whitney J75 engine got an injection of contaminated fuel and the rear end of the aircraft was immediately enveloped in a ball of fire. Fortunately, the aircrew escaped unharmed by jumping out of the cockpit and running to a safe distance to watch their plane burn (I seem to recall the aircraft was a two-seat version).

I know about this incident because I not only worked with M, but I was the airman who had to put the water on the aircraft almost a year later when the bird had been repaired and was ready to fly out. Before I could pump a drop into the aircraft, I had to deal with a line of brass from the wing commander on down tasting my water, an odd ceremony that I will always remember. I have run into ex-AF pilots years later, who at the mention of Holloman AFB, recalled seeing a safety bulletin about the F-105 incident and wondering how on earth a mistake like that could ever have happened.

In the end, Airman M got a suspended demotion one grade, lost some pay, and had the reprimand on his record. M's lawyer protected him from a worse fate by harping on the number of people involved in the chain of errors and the apparent lack of proper management at POL. The Air Force was unwilling to hang everyone, so M got off fairly easy and the base fuels officer and the senior non-commissioned officer were transferred out and presumably had the incident in their records, too.

Resources

Aviation Safety Network Occurrence # 271198

USDoT Investigation of Aircraft Accident: FLYING TIGER LINE: IDLEWILD AIRPORT, N.Y.: 1957-06-21

Carnage on the Autobahn: The Crash of Paninternational Flight 112

Aviation Safety Network Record # 19710906-0

Personal conversation regarding water injection with a USAF veteran who serviced F-105 fighters in the Viet Nam war.

Captions:

LBA = The Luftfahrt-Bundesamt, a German National Enforcement Body for Air Passengers Rights, equivalent to the U.S. Federal Aviation Administration