Wright XT35-1

Wright XT35-1Wright's T35 Turboprop Engine, et al.

by Doug Culy

Published 1 Sep 2020

Once Whittle’s work was made known (Lockheed’s and Northrop’s work was kept very secret at that time) Wright began its own gas turbine research in 1942 without United States Army Air Forces (USAAF) support, since the USAAF forbade the big engine manufacturers from doing anything except direct support of wartime needs. Once WWII ended and the USAAF could focus on future engines, it embraced the Wright design, which would become the T35, as well as other turboprops. This story is drawn from materials held by the Air Force Historical Research Agency.

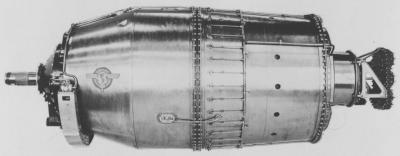

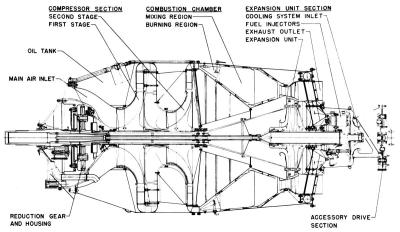

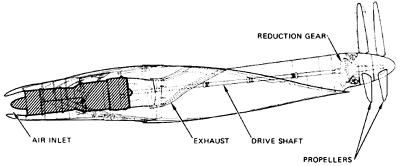

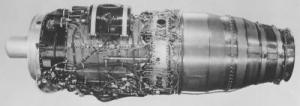

Wright was highly qualified in centrifugal compressor design, having been building its own superchargers for several years. Wright was also familiar with turbine design from having a close look (probably reverse-engineering) General Electric’s turbochargers for some time too, and Wright was undertaking the design of the compounding turbines for the R-3350 Turbo-Compound at the same time as the T35 program. By the middle of 1944, Wright had the preliminary design of a 5,000-shp engine to show the USAAF. This size was chosen to be twice the power of Wright’s biggest engine of that time, the R-3350, and comfortably above that of the Pratt & Whitney R-4360. It had two centrifugal compressors on a single shaft driven by two axial turbines also on that same shaft. The USAAF gave Wright a development contract November 22, 1944 (W33-038ac-6247), when the Northrop B-35 and Convair B-36 were the only really-big bombers under contract with range requirements that could only be met by propeller-driving engines. The Wright T35 and Northrop T37 were considered follow-ons for these bombers, which originally used the R-4360.

|

|

| XT35-1 Basic Assembly | XT35-1 Installation Diagram |

|

|

| XT35-5 | |

|

|

| Northrop XT37 (Turbodyne) | |

|

|

| Sketch of XT37 in Northrop XB-35 Wing | Northrop XT37 for XB-35 with Reduction Gear and Propeller |

The T35 was a big engine, with a diameter of 59 inches, versus about 42 inches for the T37, and 55 inches for the R-4360. The two centrifugal compressors conferred massive weight to the T35, 4,450 lb for the complete engine, versus less than 4,000 lb for most R-4360s, and 2,550 lb for the T34 (which had the same power goal as the initial T35. The original weight goal for the T35 was 3,800 lb, so Wright probably spent some time trying to reduce weight, although this was not mentioned in the archived USAF and Wright memos and letters. The growth version of the T37 is said by Paul H. Wilkinson, a not very authoritative source, to have weighed over 7,000 lb.

| -1 | -3 | -5 | |

| Studies | 1942-1944 | ||

| Contract Start | 11-22-1944 | 12-15-1946 | 5-19-1947 |

| First Run | 6-24-1946 | 10-1948 goal | 4-1949 goal |

| PFRT | 3-1949 | ----- | ----- |

| Contract End | 3-1949 | 3-1949 | 9-1949 |

| Number Engines | 4 | 2+4equiv | ----- |

| Test Hours | 223 + ~1400 | ~50 (Maybe) | 30 |

| Power, shp | 5,000 - 6,600 | 7,300 - 8,900 | 8,900 |

| Overall Pressure Ratio | ~4.5 | 9.4 | 9.4 |

| Specific Fuel Consumption, lb/shp/hr | 0.676 | 0.634 | 0.634 |

| Airflow, lb/sec | ~80 | ~100 | ~100 |

| Weight, lb | 4,450 | 5,950 | 6,200 |

| Turbine Inlet Temperature, °F | ~1,550 | 1,700 | 1,700 |

| Propeller Reduction Gear | Nose | Remote | Contra-Rotating |

| Rotating Speed, rpm | 7,080 | 7,200 | 7,200 |

| Dollars Spent, million | 3.0 | 18.7 | 1.8 |

| Diameter, inches | 59.0 | 59.0 | 59.0 |

| Length, inches | 140.0 | 152.0 | 188.7 |

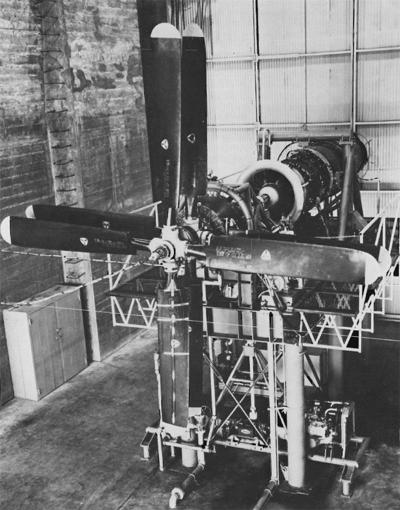

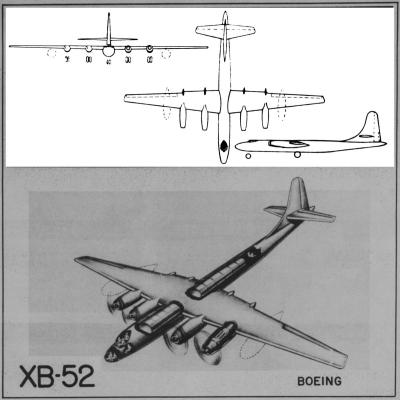

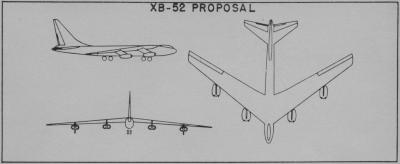

The XT35-1 was first run June 24, 1946, putting out about 4,000 shp, and by this time had been selected in Boeing studies for the next-generation big bomber. These coalesced into the Boeing XB-52 program in March 1948, and the T35 was the number-one choice for power (the Northrop Turbodyne, designated XT37, was the USAF’s second choice). Amazingly today, the T35 had been the highest priority engine in development for the USAF for several years. Before the first run, Wright believed the engine could deliver 5,500 shp, and by the time 1,500 operating hours had been run (before a Preliminary Flight Rating Test, or PFRT), Wright was able to rate the engine at 6,600 shp.

| B-52 Genesis | Engine Programs Underway |

| Bomber Studies Start April 945 | |

| T35, T37 already started | |

| J40 Start early 1947 | |

| T43 Start early 1947 | |

| T45 Start mid 1947 | |

| J57 Start mid 1947 (barrel case) | |

| T35 run June 1946 | |

| Growth T37 run late 1947 | |

| T43 Cancel by USAF January 1948 | |

| B-52 Contract Start March 1948 With Turboprop Engines | |

| T35 Fly July 1948 | |

| T45 Stop September 1948 | |

| J40 Run October 1948 | |

| B-52 Contract Mod October 1948 Requires Jet Engines | |

| B-52 Contract Mod January 1949 Requires J57 | |

| T35 Cancel March 1949 | |

| J57 Start May 1949 (Wasp Waist) | |

| J57 Run June 1949 (Barrel Case) | |

| J57 Run January 1950 (Wasp Waist) | |

| T37 Cancel during 1950 | |

| J57 Fly March 1951 | |

| T49 Start approximately May 1951 | |

| J40 Fly August 1951 | |

| T43 Cancel by Wright Aero during 1952 | |

| B-52 Fly 15 April 1952 With J57 | |

| T49 Run December 1952 | |

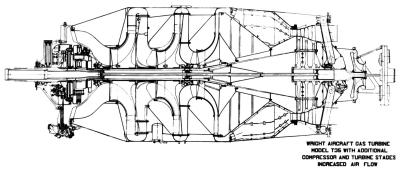

The AAF was not satisfied with the slow (410 mph or less) speed the XB-52 could obtain with six T35s, and was demanding 10,000 eshp to bring a four-engine version up to 450 mph. Wright responded by adding a third centrifugal compressor stage and a third axial turbine stage to create the T35-3, initially rated at 7,300 shp, and weighing 5,950 lb. The contract for this version (W33-038ac-14145) was signed December 15, 1946 to continue development of the engine, and interest in the T35-1 declined rapidly. By January 1948, the USAF was declaring the T35 to be its top-priority engine. Sometime before April 1948, the T35-3 had been uprated to 8,900 shp. Parts were fabricated for the -3, and first run was projected for September or October 1948. Wright was studying hollow turbine blades and recuperation in early 1948, and incorporated hollow blades in the Turbo-Compound’s turbines. Recuperation was not used.

|

|

| Wright's B-17 Test Aircraft Under XT35-1 Power, with all R-1820s feathered. Note the right rudder deflection. |

The XT35-3 Featured a Three-Stage Centrifugal Compressor. |

Video of B-17 Testbed with XT-35 Installed (through 1:40)

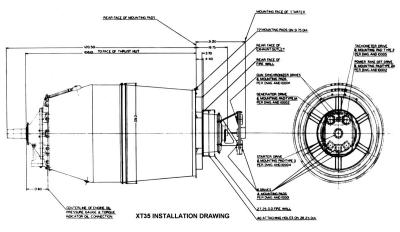

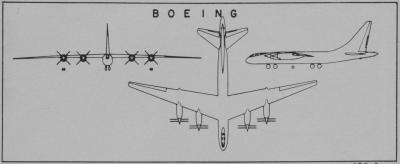

Shortly after -3 contract signing Boeing was realizing that propeller technology was inadequate to properly absorb power at 35,000 feet, and asked for contra-rotating propellers. This required a new gearbox design, and combined with changing the engine installation from tractor to pusher for a backup B-36 installation, resulted in the need for a new remote propeller-reduction gearbox, and the T35-5 model was eventually created to feature that gearbox change. Contract W33-038ac-21718 was signed on May 19, 1947 for the pusher/contra-rotating-propeller version.

In May 1948, the USAF was still saying “the T35 was imperative for the B-52”. The central problem of getting the T35 engine up to even 5,500-shp output with durability and reliability was being slowly resolved, and Wright had only been able to obtain 700 hours of engine development running by June 1948, as indicated in a report from Wright to the USAF dated June 14. Worse, it was not yet able to complete the 10-hour endurance test. However, the USAF reported that the PFRT on the -1 engine was completed in late July; so the intervening five weeks must have seen a breakthrough. This writer believes that test to have been the older 10-hour PFRT and not the 50-hour PFRT that was just coming into use.

The June report projected Wright’s test schedule would reach 1,700 hours around the time the program was canceled, and not reach its goal of 10,000 hours of development engine operation until 1953. In that era, 10,000 development running hours were typically needed to prove an engine ready for trouble-fee production (engines would be certified/qualified sooner, with the expectation that service use would find and iron out some problems). Some writers have defined the T35’s progress as “slowness” in developing the engine (the T37 too), and that it caused the USAF to lose enthusiasm for turboprops. However, the successful T34 program proceeded at the same rate overall, and even took much longer for its first run. Although unstated in the histories of the big turboprop development programs, the gearbox was at least as big a challenge as the turbine stage. Wright’s June report also projected the cost of the T35 program to reach $56 million by the time all of the major problems had been found and fixed (10,000 hrs test work).

To obtain the greater power and improved fuel consumption, Wright increased engine shaft speed from 7,080 to 7,200 rpm, and increased turbine inlet temperature from around 1,550°F to 1,700°F. The addition of the third centrifugal compressor stage, a stackup that has only been done in water pumps, increased engine pressure ratio from about 4.5 to 9.4 (combined with the speed increase). Four engines were built for development running in the -1 program, two more were built for the -3 program, supplemented by four complete sets of spares (four equivalent engines), and only two new gearboxes ordered for the -5 program; to be run on an engine by April 1949. Wright admitted it was able to average only 8 hours of run time per engine per month, so that total run time likely did not exceed the projected 1,700 hours. Wright was projecting a steady increase in the run-time rate up to about 25 hours. Wright had also asked to be able to use the common parts fabricated for the -3 to get more -1 engines running. The expected first run of the -3 engine was delayed from late in 1948 to April or May 1949. The archive does not say that this occurred, but there was development activity, even after termination into the summer. Also, the parts for the contra-rotating gearbox were built but not tested until after cancellation proceedings started, with 30 hours running done. It is not clear if this running was on a -1 or -3 engine.

Cancellation of the T35 had began to loom in January 1948 when the USAF Headquarters felt the XB-52 was the wrong plane at the wrong time, but was persuaded by Boeing and Gen. Curtis LeMay to keep going. Then, in May 1948, Boeing was directed to supplant the T35 with the Westinghouse J40, and cancellation of the T35 program became more likely, as no other need was showing up. The J40 program later proved to be unsuccessful. On October 21, 1948, Boeing was directed to replace the J40 with the Pratt & Whitney J57; and the USAF began cancellation proceedings on the T35, with a 60-day stop order being issued January 4, 1949. Termination proceedings were not completed until March 1949. It is interesting to note that as late as December 7, 1948, the USAF was adding tasks to the T35 contract; in that case, parts for the contra-rotating propeller gearbox. The -3 contract was complicated by having added in a Wright J59 engine program, and some control equipment development items, but it looks like about $23.5 million was spent on the T35 for the three contracts. In mid November 1948, the USAF said it expected program cost by the first Military Qualification Test to reach $40M.

Pratt & Whitney J57

The J57 that kicked the T35 off the XB-52 should be described. Studies began March 1946, detail design of a single-spool version began May 1947, and was proposed to the Navy as the JT3-6 with 11 compressor stages and pressure ratio of 6. According to two P&W historians, Lippincott and Connors, the Navy also asked Allison and Westinghouse to quote on producing it. Westinghouse won, and the JT3-6 became the J40, which was then picked for the B-52 as a Westinghouse engine. P&W concluded they needed to do a major design advance to compete, and further studies showed a two-spool compressor would greatly enhance engine performance and operability. The two-spool design began March 1948 featuring a constant outer diameter (barrel-shaped) compressor and turbine. Two different compressors were designed; one had a pressure ratio of 8, 13 compressor stages and was called the -8; the other had a pressure ratio of 10, 15 compressor stages and was called the -10. The first run of the -8 was in June 1949, and seal leakage was so bad that this design approach was terminated immediately and re-design was done with the compressor inner diameter held constant, resulting in decreasing outer diameter as the air was compressed through its 16 stages (called the "wasp-waist" design. The re-design was completed in October 1949, and the first wasp-waist engine ran January 1950. The 50-hour PFRT was completed March 1951 at 8,700 lb-t, and the Military Qualification Test at 9,220 lb-t in November 1951. The J57 replaced the J40 in all applications.

_2T.jpg) |

_2T.jpg) |

| Pratt & Whitney XJ57-P-1 (Initial Version) | Pratt & Whitney XJ57-P-1 (Wasp-Waisted Version) |

It can be seen that the decision for the XB-52 to go with the J57 on 21 October 1948 was when the J57 program was in an indeterminate state; the barrel engine had been cancelled and the re-design of the wasp-waist engine had just been completed, and first run was 15 months in the future. So, the decision to cancel the T35 was really based on the promise of the J40-powered B-52, and confidence in Pratt & Whitney. To qualify the J57-1 cost $84 million.

|

|

| XB-52 Evolution: June 1, 1946 | XB-52 Evolution: November 15, 1947 |

|

|

| XB-52 Evolution: December 15, 1948 | XB-52 Evolution: December 15, 1948 |

| AAF Long-Range Turbine Bomber Requirements | Apr 1945 | |

| Specific Requirements 10K lb, 10K mi, 450 mph | Nov 1945 | T35, T37 Available |

| Boeing 462 Offered (non-swept, 360,000 lb) | Feb 1946 | With 6 x T35-1, 410 mph |

| Study Contract for Boeing 462 | Jun 1946 | None for Convair, Martin |

| 464-16,-17 Offered (480,000 lb, 3,750 mi) | Dec 1946 | 4 x T35-3, LeMay Request, 400 mph |

| USAF Give Boeing more $ for 464-17 Study | Feb 1947 | With T35 |

| Cancellation considered by DOD | Early 1947 | Fought off by Boeing, LeMay |

| 464-25 Offered | Mar 1947 | 12K lb |

| USAF Issue New Requirements | Jun 1947 | 10K lb, 12K mi, 400 mph |

| 464-29 Offered (400,000 lb) Mild Sweep | Aug 1947 | 10K mi, 455mph |

| USAF Contract for Mock-Up | 2 Sep 1947 | With T35-3 |

| USAF Issues New Requirements (8k mi,550 mph) | Dec 1947 | $2.35M Spent to Date |

| USAF Mock-Up Inspection | Jan 1948 | |

| Cancel Contract/Re-Start | Jan 1948 | |

| USAF Go-Ahead for 464-35 (300,000 lb) | Feb 1948 | With T35-5, 500 mph, 8K mi |

| USAF Contract for 2 Prototypes, due 2-51 | Mar 1948 | $29.4M, Still with T35 |

| USAF Ask for Use of J40 | May 1948 | Study |

| Boeing Proposed 464-40 with J40 | Jul 1948 | 5.3K mi, 280,000 lb |

| USAF Asks Boeing to Use J57 | 21 Oct 1948 | 464-49 Proposed 24 Oct 1948 |

| USAF Contract Mod to Use 8 x J57 | 26 Jan 1949 | 330,000 lb, 35° Sweep |

| USAF Mock-Up Inspection | 29 Apr 1949 | |

| Air Staff Approval | 1 Oct 1949 | |

| Boeing Proposed Definitive XB-52, 464-67 | Nov 1949 | 390,000 lb, 7K mi, 10K Payload |

| USAF Selects 464-67 as B-52 | 24 Mar 1950 | 519 mph Cruise |

| USAF Approves Production of B-52 | 9 Jan 1951 | First Batch = 13 |

| XB-52 Rollout | 29 Nov 1951 | |

| YB-52 First Flight | 15 Apr 1952 |

Wright Soldiers On

Turboprops were not yet dead at Wright, as it had purchased, and been given responsibility for, three turbojet programs, the J37 (Lockheed/Menasco L-1000, a 2.5-spool axial engine), the J65 (Bristol-Siddeley Sapphire single-spool axial engine), and the J67 (two-spool Bristol Olympus axial engine) that it then converted to turboprops, the T43, T49, and T47, respectively. The T43 was kept alive by Wright until 1952, apparently without having been run as a self-sustaining engine. Lockheed and Menasco were able to get the engine to run with motoring assistance by a starter, but the turbine never produced enough power to run the compressor. Since Wright spent $638,500 on the T43, it can be assumed there was some progress toward getting it to produce net power. Two T49s helped power the XB-47D in August 1955, as a single-shaft engine, then work was started on a free-shaft version; but the T49 program was cancelled late that year. Wright took so long to get the J67 converted to U.S. standards, that both the J67 and T47 were cancelled after they were surpassed by the advancement of other engines.

|

|

|

| Lockheed/Menasco/Wright XJ37 | Wright XJ65 | Wright XJ67 |

|

|

|

| Wright XT49 | Wright XT47 |

Wright T35 for the B-36?

This is not just the story of the T35 on the B-52, but is also about the T35 on the B-36. Recall that the T35 was the designated alternate to the R-4360 on the B-36, and the T35-5 was really created for that airplane; so the question is why did the USAF not get a turboprop for it? There are three likely reasons. First, the budget did not permit that great an expenditure because the USAF total budget from the end of WW2 until the start of the Korean war was quite constrained; and getting F-84s, F86s, B-47s, and B-52s was a higher priority. Second, there were durability problems with the early turboprops, as evidenced by difficulty in their completing the 50-hour Preliminary Flight Rating Tests and the 150-hour Military Qualification Tests. Third, these engines had a combination of efficiency and power-to-weight ratio that did not provide a range boost of sufficient magnitude to justify the expense of going ahead with them. It may also have been the case that the USAF did not anticipate that the B-36 and the heavier transports on the horizon would be in service long enough to also justify the expected expenditure because the B-47 was clearly demonstrating that the bomber jet age had arrived too.

Given the USAF requirement for at least 10,000 eshp and contra-rotating propellers, The T35-5 was not going to be available until about 1951, the T37 had a PFRT in May 1950, the T49 was further in the future, passing its PFRT in August 1955, and the T57, later yet, with PFRT in October 1956. The other turboprops in development would not have been factors in consideration for various reasons. The B-36D was the first version to feature turbojets (J47s) for additional power, and study for that addition began in July 1948, with the program being formally kicked off January 1949. The first one flew in March 1949, testifying to the urgency of getting its speed up; and that model was in service by the end of 1950. The J47 was in production for the B-47 bomber, and that engine’s cost was decreasing fast as a result of high production rates. Further, it was very easy to add to the B-36, because the twin pod for the B-47 was little more difficult than a simple bolt-on.

If changing to turboprops was affordable, the next consideration would be the impact on range. This impact is approximated by using the take-off ratings that we know, dividing power by the engine’s weight and specific fuel consumption. Those values are: for the T35-5, 2.36; the T37, 2.56; the T49, 3.68; the T57, 4.13; the R-4360, 2.34; the J47 about 2.5;no better than the R-4360 and the Russian NK-12, for the Tupolev Bear bomber, at 4.09 (which did not have its PFRT until 1953). The right engine was just not available as soon as the USAF felt was absolutely needed. The range factor for the J57-1 was 2.76, and today, this factor for the Airbus A400M’s TP400D6 is 5.45. It is clear that the neither the T35 nor any other turboprop was going to make it onto the B-36 or the B-52.

However, as the Tu-95 was to demonstrate in 1955, a big swept-wing turboprop bomber could fly at 550 mph (see Gordon). The early Boeing proposals for the B-52 had also laid this out, as had Convair for a design evolution of the B-36 (proposed as the F Model, see Ethell) late in 1950. How the Tu-95 differed from these was that the propeller problem was solved by using slow rotation and flat pitch, and the NK-12 had an honest 12,000 shp, soon to be upgraded to 15,000.

The Others

Three other big U.S. turboprops deserve mention, the P&W 6,950-shp T34, 10,000-shp T45, and 15,000-shp T57. The T34 was P&W’s first axial engine, and started development with a goal of 3,550 shp. The T45 was the turboprop version of the first J57 (barrel shaped), and the T57 being the turboprop version of the later J57, with the “wasp-waist”, both also all-axial. Design of the T34 started June 1945 achieved near 5,500 shp at first run, at a weight of only 2,550 lb. It had 4,100 test cell hours at qualification, but this writer does not know how many test engines were in the program. The T45 was actually the first engine in the J57 family, and was a two-spool engine designed with a constant-diameter compressor, and to be easily be converted to a two-spool jet. Design of the T45 started July 1947, and P&W ordered enough T45 hardware to build two engines, but found on rig test, that compressor seal leakage was so great at the larger diameter that the engine had no net power. This is what motivated the redesign to the “wasp-waist” configuration, with much smaller compressor seal diameters, and the T45 was cancelled September 1948 without having been run as a whole engine, and redesign proceeded directly to the J57. The T57 was started in 1953, one year after qualification of the “wasp-waist” design, to power the Douglas C-132 transport, which was cancelled in March 1957 along with the T57. Six T57 engines were built, over 3,100 engine test hours were run, and the T57 was flown October 1956. It still is the biggest turboprop ever built, and probably capable of well over 30,000 shp when updated to today’s technology.

With only the U.S. Air Force Historical Research Agency archives available to research these programs, historians are limited in the understanding they can gain. Maybe Wright Aeronautical archives will yet appear.

| Engine | Power | Weight | Start | Run | Fly | Qual | SFC | R-Ractor |

| Pratt & Whitney R-4360 | 3,500 | 3,482 | Nov 1940 | Apr 1941 | May 1942 | Jan 1945 | 0.43 | 2.34 |

| Pratt & Whitney T34 | 6,950 | 2,550 | Jun 1945 | Dec 1948 | Apr 1950 | Dec 1951 | 0.62 | 4.40 |

| Curtiss-Wright T35-3, -5 | 8,900 | 5,950 | Nov 1944 | Jun 1946 | Jul 1948 | ------- | 0.634 | 2.42 |

| Northrop T37 | 10,400 | 7,000 | Jun 1941 | Feb 1944 | ------- | ------- | 0.58 | 2.56 |

| Allison T40 | 5,100 | 2,500 | Jun 1946 | Jun 1948 | Apr 1950 | Apr 1952 | 0.65 | 3.14 |

| Curtiss-Wright T43 | 10,000 | ~3,200 | Feb 1946 | maybe | ------- | ------- | 0.61 | 5.72 |

| Pratt & Whitney T45 | 10,000 | ~6,400 | Jul 1947 | -------- | ------- | ------- | ----- | NA |

| Curtiss-Wright T49 | 10,400 | 4,350 | May 1951 | Dec 1952 | Aug 1955 | ------- | 0.65 | 3.68 |

| Pratt & Whitney T57 | 15,000 | 6,600 | Jan 1953 | Sep 1954 | Oct 1956 | ------- | 0.55 | 4.13 |

| Kuznetsov NK-12 | 11,834 | 5,070 | July 1950 | 1951 | 1953 | Dec 1955 | 0.57 | 4.09 |

| Europrop TP400D6 | 11,000 | 4,034 | May 2003 | Aug 2005 | Dec 2008 | Dec 2011? | 0.50 | 5.45 |

| Lockheed J37 | 5,100 | 1,700 | Jun 1943 | May 1946 | ------- | ------- | 0.61 | 4.92 |

| Westinghouse J40 | 7,500 | 3,000 | Apr 1947 | Oct 1948 | Aug 1951 | Jan 1951 | 1.08 | 2.31 |

| General Electric J47 | 5,000-6,000 | 2,475-2,650 | Mar 1946 | Jun 1947 | May 1948 | Mar 1949 | 0.90-1.10 | 1.8-2.6 |

| Pratt & Whitney J57-0 | 870 | 4,800 | May 1947 | Jun 1949 | ------- | ------- | 0.90 | 2.28 |

| Pratt & Whitney J57-1 | 9,220 | 4,200 | May 1949 | Jan 1950 | Mar 1951 | Nov 1951 | 0.795 | 2.76 |

References

Bagwell, M. 1949. The XB-52 Airplane. Air Force Historical Research Agency 202.1-43.

Connors, J. 2009. The Engines of Pratt & Whitney: A Technical History. Reston, VA: American Institute of Astronautics and Aeronautics.

Dorr, R. and L. Peacock. 1995. B-52 Stratofortress: Boeing’s Cold-War Warrior. Oxford: Osprey.

Ethell, J. and J. Christy. 1981. B-52 Stratofortress. New York: Scribners.

Fenwick, A. 1950. Case History of the T35 Turbo-Prop Engine. Air Force Historical Research Agency K202.2-63 V.1-V.3

Gordon, Y. and D. Komissarov. 2009. Tupolev Tu-95/Tu-142. UK: Midland.

Gunston, B. 1986. World Encyclopedia of Aero Engines. Somerset, UK: Patrick Stephens, Ltd.

Jenkins, D. 2002. Magnesium Overcast: The Story of the Convair B-36. North Branch, MN: Specialty Press.

Knaack, M. 1988. Post-World War II Bombers. Office of Air Force History.

Lippincott, H.H. 1985. Pratt & Whitney Enters the Jet Age, Howmet's Casting About, Part of a series called Classic Turbine Engines.

Lloyd, A. 1988. B-52 Stratofortress in Detail and Scale. Blue Ridge Summit, PA: Tab Books.

Lloyd, A. 2005. Boeing’s B-47 Stratojet. North Branch, MN: Specialty Press.

White, G. 2006. R-4360: Pratt &Whitney’s Major Miracle. North Branch, MN: Specialty Press.

Wilkinson, P. 1954. Aircraft Engines of the World-1954. New York: Paul H. Wilkinson.