Stories & Essays 2

Fingerprint Remover

by Michael Smith

Anyone who’s ever been new to an organization, particularly a military organization, has probably experienced some level of hazing, however innocuous it might have been. As a young sailor, my very first assignment was as an engine mechanic working the mightyLockheed P-3C Orion with VP-30 out of NAS Jacksonville Florida. I was quickly indoctrinated into the world of aviation maintenance within the military. I fell victim to grabbing a bag full of exhaust to test, I’ve been on the search for several feet of flight line, I even went looking for an “after” stand because we already had a before (B-4) stand. All of these little pranks were all in good fun and I do recall returning the favor to several young sailors over the years. In any case as soon as I was no longer the new guy, I no longer had to worry about these fun little assignments.

Around the time I was up for orders, I picked up Petty Officer Third Class (E-4) and showed up to VAW-121 in Norfolk, VA as a freshly minted AD3. Figuring that I was no longer a "new" sailor and had some experience as a mechanic I didn’t think I’d have to worry about being fooled into these silly little assignments, even on a new airplane. Well, about two weeks into this new command I was about to get some training on prepping an aircraft for flight by completing a pre-flight inspection on the Grumman E-2C Hawkeye that was scheduled to fly that evening. I was really excited, so I was getting tools and tech data ready. My supervisor, an AD1, asked me to go to the Hazmat locker and get some fingerprint remover…and there it is I thought! I’m going to go on a wild goose chase looking for “Fingerprint Remover” come back to the shop and get laughed at. I thought about it for only a second before I decided I would play along. Instead of going to the hazmat locker where the “fingerprint remover” was, I was going to go home, have lunch, pick up some uniform items I needed at the exchange and return saying I was unable to find the “fingerprint remover”. I showed back up about two hours later and did my best to look exhausted. My supervisor asked where the hell I had been and I came up with a story about how I looked all over our hanger, all the other units hazmat lockers and even the base hazmat storage depot and that I couldn’t find any of it anywhere, I tried to let only a little sarcasm into my story.

My AD1 let out a heavy sign and told me to come with him. We walked into the next door over in the hanger, which was the Hazmat locker and AD1 asked the guy working there for a can of “fingerprint remover”……They brought us a can of fingerprint remover. So as it turns out, the NP2000 propeller system (the eight blade scimitar system) has a nickel sheath on the leading edge that is supposed to be cleaned each inspection with a light solvent colloquially known as fingerprint remover. I tried to explain to my AD1 exactly what I did, why I did it. He did see the humor in it, but I owed him two hours. In the end, I cleaned all four aircraft props with fingerprint remover and I learned that fingerprint remover is a real thing!

Ramon Said to Give You This, Trust Him

by Tony Vasko

In piston engine days, mechanics were busy souls. Even a turnaround seemed to demand some plugs, coil and leads at the least. Much of the trouble, the ignition system aside, came from the vibration and pounding of the big radials. Things plain wore out; lines chaffed, exhaust system joints and clamps leaked and electrical connectors became loose.

The R-2800s on the DC-6 are fitted with a BMEP system, which measures the torque the reduction gear is undergoing. With charts it was possible to calculate the horsepower the engine is producing thereby assuring the flight crew of its health and giving them a means of establishing power settings. The transmitter was fitted to the nose case of the engine, which exposed it to the howling blast of the propeller. A connector plug on the end of a flexible conduit was attached. I might add there were no spinners on the props at that time as became common on the DC-6 later on.

The wires were connected to the pins in the plug by solder. The solder job had to be of high quality for the vibration was fierce. Given the location, the nose of a reciprocating engine and 18 inches behind the prop it is no surprise that the solder joints often broke. Soldering the wires back on in a hangar was a snap. Soldering wires on top of a ten-foot ladder in a screaming winter wind was something else especially since the nearest electric outlet for a soldering iron was a half-mile away. The industry's answer was the "Hot Shot" soldering iron.

This instrument of torture had a working end that unscrewed open revealing a breech into which one inserted a cartridge that resembled a metallic shotgun shell. After screwing it back together, one grasped the wooden handle and pulled out a button at its end. It was spring loaded and upon release drove a firing pin into the end of the cartridge inside. The cartridge would combust fairly slowly and the resulting heat would warm the soldering tip. Rule #1 was to point the button AWAY from you when firing it as there had been occasions when the cartridge combusted rapidly, split and functioned like a true shotgun shell using the rod as the slug. There were horror stories circulating, doubtless like urban legends, about people being skewered by them.

Under ideal conditions, tropic heat and no wind you could obtain about one minute of working life from a cartridge. That meant if everything was set, solder in hand, the plug in place, and the wire tinned and dipped in rosin you could expect to solder one wire to a pin. In a screaming wind and an OAT (Outside Air Temperature) of 5 degrees F, the working life was reduced to mere seconds. With canvas draped over you, two irons and helpers it was barely possible to solder a plug. Add to this the frustration of trying to pull enough slack wire out of the conduit so you could work and trying to read wire and pin numbers to make proper connections. The picture is now set.

Ramon was a semi-mythical mechanic in San Juan, Puerto Rico (SJU). He was reputed to be five feet tall and four feet wide, tough as nails and obviously possessed an engaging manner that captivated the flight crews. His veracity was unquestioned. On one occasion I did a walkaround of a DC-6 that had just arrived. The #3 engine had a large hole burned through the cowling on the outboard side. I procured a ladder and climbed up to make a close inspection. The exhaust stack from a forward cylinder had fractured, allowing the hot and often flaming gasses to escape. It had burned a hole in the cowling, cooked the cylinder baffles just aft of it, an ignition coil and leads and burned off the Edison fire detector probe on the fireshield.

The last passengers had deplaned so I mounted the boarding stairs and went forward to the cockpit. The airline's maintenance rep was debriefing the flight crew when I interrupted them with my findings.

"You know we had a flight return because of fire warning on takeoff", said the Captain. "We shut the engine down and the fire warning stopped so we returned to SJU. Ramon checked out the engine and said the fire detector was dirty but there was no problem. He said we might get it again but not to worry, it would stop. We took-off again and. sure enough, the fire warning went off again but, just like he said, it stopped".

"It stopped because the fire warning sensor was burned off by the exhaust leak". The crew looked unhappy and they descended to the ramp to look at the hole in the cowling. I started to follow them but the maintenance rep grabbed me. "Don't ever do that again. They'll lose confidence in Ramon".

Little things like that aside, I had to admit he did move airplanes. The #1 BMEP had gone to hell on the way south to SJU. The quick turn was made, the #1 BMEP was placed on Minimum Equipment to allow the aircraft to legally operate with it broken and the airplane departed from the sunny, warm clime of Puerto Rico for the frozen wasteland of Idlewild. The #1 BMEP was still inoperative.

On arrival I met the crew along with the airline's maintenance rep. "Oh yes, the #1 BMEP is inop", said the Flight Engineer. He fished in his flight bag and extended something to me. "Ramon said to give it to you. You'll need it to fix the problem".

I gazed down at the connector for the BMEP transmitter in his hand. One wire was broken at the plug. One wire would have been easy to resolder. Instead, Ramon had used his dikes (diagonal cutting pliers) to cut the wires about four inches away from the plug. The four inches of wire that provided the slack that you needed to repair the plug, the four inches of wire that had the numbered labels on it identifying the wires so you could make the proper connections. I didn't cry. Strong mechanics don't. The howling winds shook the airplane and the snow pelted against the skin.

I raised my walkie-talkie and called the hangar. "LASI base from LASI line. Send up two gross of Hot-Shot cartridges, some wire, a crimper and some wire to wire splices". I went to the truck and contemplated working in sunny SJU.

More Musings

by Tony Vasko

George Prill, owner of GSE Today, a ground equipment magazine, related a couple of C-46 stories.

The C-46 was operating under a restriction on weights having killed a lot of civilian passengers. It was the aim of the Non-scheduled Airline Association to get full certification back for the C-46 so they could operate at 48,000 pounds max gross. They did several things to achieve this. Among them were fitting "C" cylinders on [R-2800] "B" engines. Another was to rework the cowling air entrance which he said was okay at higher speeds (lower angle of attack) which required two engines running but very poor at a high angle of attack slow flight as occurs during single-engined flight. This was fatal of course as that is when you are really pulling power and need all the cooling you can get.

One of the non-sked airlines that advertised 4-engined safety while flying C-46. Since they operated at night, few noticed that there were only two out there until it was too late. However a pugnacious passenger did make a scene out on the ramp and held up boarding. The owner took him up in front of one of the engines and, using a flashlight, pointed out the front row and said, "That's one engine. Now look behind it. See that row of cylinders? That's the second engine. Two plus two makes four". Poor passenger could only nod his head and get on board. I guess that meant a Stratocruiser had 16-engined safety with its 4360's.

Don't Run if It's on the Blocks

by Tony Vasko

|

Not if you've just set a R3350's injection pumps synchronizing bar to a cold clearance to 0.010" and haven't swung the calibrated adjusting blocks out of the way.

Some background. The R3350 started life as a carbureted engine. Among its many problems, and there were many, it suffered from poor mixture distribution among its 18 cylinders. The result was that some cylinders ran hotter than others.

Even worse, there were big problems with induction system fires and it is said (rather unkindly) that more B-29's were lost to Curtiss Wright than to the Japanese. This remark was passed on to me by an ex-B-29 flight engineer who flew in them on raids so please take no offense.

It was not until the near end of the war that Wright was finally compelled to utilize direct fuel injection to attain the necessary even distribution of fuel to each cylinder. While there were later carbureted versions of the Wright R-3350 on military aircraft, all the ones I came into contact in the commercial aircraft world were direct fuel injected.

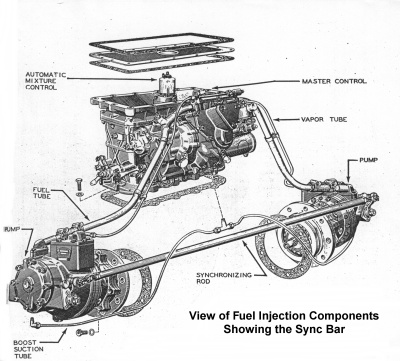

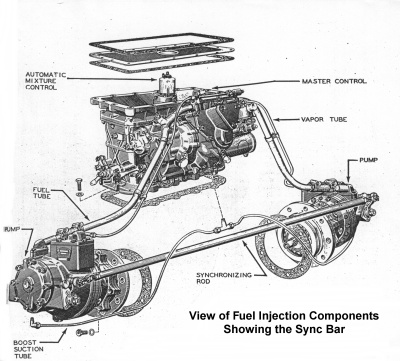

Simply put, the Bendix Pressure carburetor became a "master control" which fed two high-pressure injection pumps. Each pump had nine pistons and the volume of its output was determined by an internal swash plate. Each pump then fed its own bank of cylinders with each cylinder receiving the output of one piston in the pump. Since equal fuel flow between banks is essential, each pump swash plate had an external lever or arm. The two arms were linked by a fairly heavy synchronizing rod that ran across the back of the engine. This was carefully adjusted so that the arm on each pump assumed the same angle as its mate on the other side of the engine thereby making the internal parts pump at the same rate.

To adjust this bar, a calibration block was fitted adjacent to each arm. It was carefully ground to a precise dimension. One loosened the nut securing it and, pushing the synchronizing rod over, rotated the block so it came under the arm. When the synchronizing rod was released, spring load brought the arm against the new, calibrated stop. This was actually about the point where the arm would be if it was pumping the fuel at cruise power. The opposite side was set up the same way and the rod length was then adjusted so there was a gap of 0.010" on the right side. This allowed for the inevitable expansion of the engine case when it was hot. The blocks were then lowered and the arms, tied together by the synchronizing rod would swing to the idle position.

I was working midnight shift, the fate of low seniority mechanics. Number 2 engine had been worked on second shift. The swing shift bodies departed and the midnight rats came out to finish the work and push the Connie out to the blast fence for a runup. I was assigned to the Captain's seat where there was nothing to do but "ride the brakes" to make sure we didn't slide or jump the chocks. You could maybe twiddle with the pinball machine which in actuality was the deicer boot controller. You also got to operate the magneto switches on start and during the magneto check.

The right engines were fired up first. No problems. #2 spun up, "7, 8, 9 blades, switch on". The belches of smoke out the Power Recovery Turbines (PRTs) was absolutely normal. What was not was the flood of fuel, mostly burning, that seemed to spout from the PRTs. The engine was running, somewhat reluctantly but absolutely pouring fuel. I could see it out the sliding window next to me. It was not pretty. I told the lead mechanic, sitting at the flight engineer's position of our little fiery problem and advanced the throttle. The higher the power, the better it was until at 2400 RPM all appeared normal.

With the immediate crisis over we looked at the fuel flow. It was normal. We slowly throttled back but the fuel flow did not drop much. Instead the PRTs began to belch spectacular and very lurid yellow flames. We opened up again and did some thinking. The lead mechanic's face lit up. "It's on the blocks", he said. He had been around a long time and had encountered (and maybe committed) a few errors in his time. He closed the mixture to idle cut-off. The engine continued to run. With the swash plates in the injection pumps held at a cruise setting, the injection pumps were able to pull a negative pressure and get fuel. The engine would not shut down in the normal manner.

"Pull the fire shutoff handle", said the lead mechanic. This blocks the flow of fuel and hydraulics to the engine in the event of a fire. This was another control I could reach on the overhead. I pulled it did so and the engine ran for a few moments and then, reluctantly shut down. A new lesson. "Don't run if it's on the blocks".

We had another incident of severe "torching" which was the term applied when the engine exhaust stacks put forth more than the usual amount of flame. Strange things can happen when things are misconnected. The deicer boots received their pressure to inflate from two vacuum pumps each mounted on the inboard engines. These also, as named, produced a vacuum that deflated the same boots to hold them tight to the airfoil. Vacuum pumps were a pain. They failed often and were oil lubricated. The oil became mixed with the air they were pumping and you didn't want that to get inside the rubber deicer boots. An oil separator was fitted in the aircraft to separate the oil from the air and a vacuum pump oil return line ran from the pump to the oil separator. The line was attached to a fitting on the firewall.

During an engine change on a Constellation or other transport aircraft, the engine separates from the aircraft at the nacelle firewall. There were a lot of lines and fittings on the firewall and of all sizes. On engine removal, all the lines, hoses, control rods or cables, electrical plugs had to be disconnected and the engine mount bolts be removed. Hopefully, by this time, you had hooked up a crane to support the engine. On installation they all had to be reconnected.

Most lines and connectors were of different sizes. Through the choice of Mr. Murphy, there were two fittings on the L-1049 firewall that were of the same size and they were near each other. One was for the oil return line from the vacuum pump. The other was for a line that came from the master control. The master control was fitted with a little float valve that vented air out should any come in from the fuel pump. The vented air, and some fuel occasionally, was routed back to one of the fuel tanks. Through sheer genius the vacuum pump oil return and the master control vapor return lines were the same size. Lockheed had depended on the clamping and routing of the lines to prevent a misconnection. They did not reckon on the sheer persistence of a misguided mechanic. With enough work, the two could be crossed.

The vacuum pumps only produce pressure when deicing is selected "ON". The vacuum pump oil return line therefore normally had no pressure in it. On the runup that night I was once again riding brakes in the Captain's seat. I was instructed to check the deicer boot system. Since all the interesting things on a Connie happen at the flight engineer's panel, I welcomed the opportunity to play with the so-called pinball machine. It had lots of lights and toggle controls on it. I turned it on and saw a gratifying rise in deicer pressure. Less gratifying was the eruption of flame from the #2 engine power recover turbine flight hoods.

My attention having been aroused, I quickly switched off the deicing system. Almost immediately the fire stopped. I looked at the lead mechanic who said, "What have YOU done now?"

After clearing that matter up, that there was nothing I could do from that seat to make the engine belch flame, we experimented. Indeed the deicing system had a very visible effect on #2 engine. Turn it "ON" and the engine torched spectacularly, when "OFF" it didn't. We finished the run without further test of the system.

On the last engine change, someone had inadvertently crossed the vapor return line from the master control with the oil return line from the vacuum pump at the firewall. Through more clever planning by Mr. Murphy these lines were not only identical in size and near each other but there was enough slack, if you took off some clamps, so each could reach the other fitting. Air pressure, only generated when the deicing system was "ON", blew down into the vapor return float valves in the master control. This screwed up the fuel metering to a fare-thee-well. Further, and what drove a mandatory service bulletin that changed the size of one of the lines was that fact that when deicing was "OFF" fuel was being directed into the oil-air separator and even out to the boots if they were activated. A truly explosive situation was possible.

Engines: Observations of a Mechanic and Machinist

|

Engines — my first love (Just don't tell my wife). An engine, to me, has pistons, connecting rods, and a crankshaft. Well, I have a distant interest in the other heat engines. But the internal combustion reciprocating engine has been my life-long interest, since a very young age. For me, such an intense interest in these wonderful machines, at so young an age, fostered the imagination, and helped develop a love for what seemed to be a living entity. Though it was made of metal and by man, it LIVED! To me, it would consume food (fuel), it breathed, it had its waste products, it had blood, and when it had life it was nice and warm. Funny thing, as an adult, I still feel this way about them at times now.

In spending so much time studying engines, working with them and on them, I came to a realization many years ago that the ultimate internal combustion engine—the ones that are the most elegantly designed and constructed—are the aircraft engines. Yes, most all the competitive engines used in motor sports are excellent. But they are outcroppings of the aircraft engine. As far as the design and construction goes, almost everything you see on a racing automotive engine was done on an aircraft engine years before. Things like fully machined crank chain parts, nitrous oxide injection, water injection (ADI), etc. I have to laugh at all the racing and automotive guys within the last 40 so years, who think they discovered something new when actually it was done on aircraft engines many years ago. Just think, if it weren't for people like Sir Harry Ricardo and Charles Fayette Taylor, where would we be today?

Until recently, I thought I was the only person interested in the last of the large aircraft recip engines. Then I saw Graham White’s Allied Aircraft Piston Engines of WWII. Actually, I always thought others existed, but with such a lack in written material on the subject, I had my doubts. As far back as the 1970s, I wanted to write a book on the R-4360. However without the connections or the knowledge of where to start, and no affordable word processor available, plus life in general, it never came about. Besides, after seeing Graham’s great book on the R-2800, I figured he would probably be the one to write the R-4360 book. I know if he does, it will be as good as or better than R-2800.

Of all the reciprocating engines that have been designed for use in aircraft, the ones that stand out to me are the large radials. They represent the epitome of engineering design and manufacturing. There are no mass produced engines of that quality manufactured today. In fact, I was told by a manager of an engine overhaul facility that works on the R-2800s, R-3350s, etc. that he has gone to various machine shops to have parts made, and was told, "Sorry we can't make that." This is in an age of computerized machine tool controls! But he, I, and any other real machinist know that you can machine any part with the correct fixture and process. I just thought it funny.

Not that those big beautiful engines are perfect, and couldn't be improved here and there. You have to remember they where designed and built long before the "new exotic materials" came into general use. Imagine if they where being built today, with some of the high quality materials we have now. And manufacturing processes that exist now. As has been mentioned before by others that have written on this subject, the engineers didn't have the sophisticated computers that they have nowadays to crunch the numbers and model and test the parts. In most cases, all they had was a slide rule. Something else that is not apparent is that the formulas within those computer programs may have come from those engineers of years ago.

Next time you look at one of the big air-cooled radial engines, consider of all the thought that went into creating it. Sure, you can say that in the other aircraft engines that the same amount went into them. I don't think so—even if you consider the experimental liquid cooled radials. Why? Because of the complexity of the cooling fin design and manufacturing processes. It is way more difficult to machine cooling fins than to cast a water jacket. Then there are the other smaller complex parts and gear trains. Yes, you need to consider the design of the fixtures and special machinery used to manufacture the engine. So much more is involved that is not apparent to most people.

I find it very sad that in history of any famous machine, the very persons that are completely forgotten are most likely the ones that caused it all to be. The machinists, the assembly personnel, the test personnel, or the inspectors. Finally, Kimble McCutcheon in his book Tornado showed these important people some fame. Just think of the great ideas these people could have contributed. But instead of them receiving the proper recognition, it goes to some engineer or manager. It's the machinist that says, "That will never work, here is how to do it." I know - been there, done that. It may be an assembly person that has to help redesign a part or figure out the process to assemble a complicated assembly. I would bet that many, many great ideas where conceived by such people who knew there would be no recognition or reward. Without those people, maybe that engine would have never been as successful—just speculation on my part.

In those days there weren't any fancy computerized machines. Intricate parts were done the old manual machine way. In addition, the manual machines didn't have such things as zero lash ball lead screws, so on some of them, especially the milling machines .001 could be a difficult tolerance to hold. When you do this kind of work, it really makes you appreciate what was accomplished in the old days.

I mentioned materials earlier. Something I couldn't understand is why use magnesium in an aircraft engine? I realize it is a strength-versus-weight issue. However, magnesium is highly flammable, especially in the form of chips or shavings. It is also susceptible to corrosion. I saw the result of a large radial engine that went diving in salt water. It was flushed when the aircraft was recovered. However, the flushing job did not remove the salt water from the lower areas of the cases and the internal areas of the impeller/diffuser housings. From what I saw, magnesium does not like salt water. In a month or so of setting, waiting for tear down and inspection, holes were completely etched through some areas, mostly near the drains. I think all the magnesium parts where red tagged due to corrosion. Some of the steel parts, such as the connecting rods, were also rejected because of rust pitting. Pitting causes a stress riser that can be lead to a fatigue crack then failure of the part.

The story of the salt water diving engine brought to mind my desire to acquire an engine for a running display, which is not an easy task, and how most of the people that contacted me with an engine to sell have no idea of what they may or may not have. It may be a good corrosion-free engine, or it may be a pile of scrap parts. I don't think anyone would want to pay thousands of dollars for low value parts. If the engine is a recent overhaul with papers, and has been stored in a pressure can, then it may be worth the big dollars they are asking. However, if it is over 12 years since overhaul, then you have no idea what you are getting unless you dig into it. Why would an enthusiast want to spend top dollar for something you’re gonna put on a stand? The money would be better spent making it look good. I'm not writing this last part for the collector as much as I am for the person that thinks his engine is gold plated inside. If the parts are not airworthy, they have the value of scrap metal. All FAA certified overhaul shops for the big round engines will toss ‘em. I was told at one time that they want them out of circulation. They don't want them to accidentally wind up in an engine. I just wish the folks would realize this and let the prices drop accordingly. Some scrap parts may be just fine for a stand engine. An engine, full of red-tagged parts, should not be priced as an airworthy engine, or core. Just remember, you have no idea what you are getting until you look inside. An unpreserved engine, not protected from moisture and humidity could be a rusted, corroded scrap heap. Even as scrap its value is low because it costs time to break it down to the separate metals.

Yes at times I still have those same feelings about engines that I did as a young child. To me and others that are similar, engines are alive!