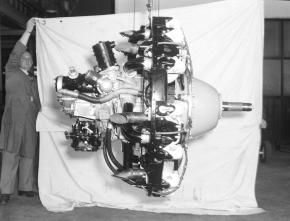

Photo Courtesy of Maurice Austin

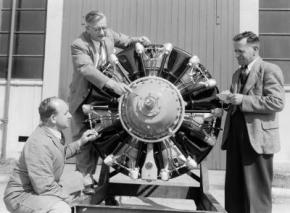

Photo Courtesy of Maurice Austin

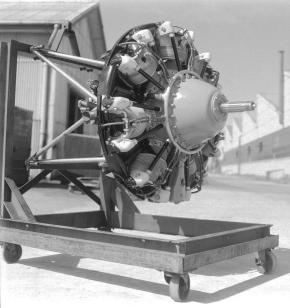

Photo Courtesy of Maurice Austin

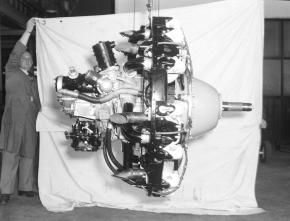

Photo Courtesy of Maurice Austin

Commonwealth Aircraft Corporation

|

Commonwealth Aircraft Corporation (CAC) was established in 1936 at the instigation of the Australian government, which was worried that war might be coming and that supply lines between Great Britain and Australia might become problematical. CAC built aircraft and engines under license, and also undertook original designs of aircraft and engines. Prior to the introduction of its own engine, CAC had built Pratt & Whitney R-1340s, R-1830s and Rolls-Royce Merlins. The R-975 Cicada, CACs first original engine design, was built in Melbourne Victoria Australia around 1952 and was meant for fitting to the Winjeel trainer. It was based on components from the P&W R-1830, including front and rear crankcases and cylinders. The ready availability of reconditioned P&W R-985 Wasp Juniors killed it off. Only two were made. |

|

|

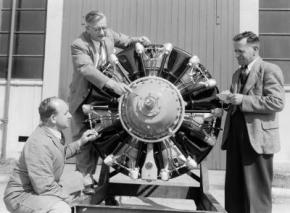

| CAC Cicada Photo Courtesy of Maurice Austin |

CAC Cicada Photo Courtesy of Maurice Austin |

|

|

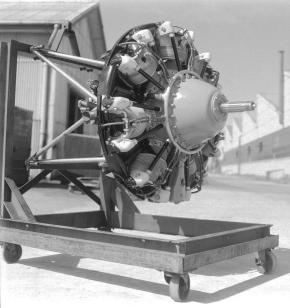

| CAC Cicada Photo Courtesy of Maurice Austin |

CAC Cicada Photo Courtesy of Maurice Austin |

The Cicada

CAC had built up a lot of experience in piston engine manufacture during the war years, especially with the development of the R-1830 into an R-2000. In light of this experience, it was felt that the company could develop an indigenous engine especially for the basic trainer and later use in the Wallaby regional airliner.

The Cicada layout was basically a single bank of the R-1830 Twin Wasp engine, which allowed some use of existing tooling and parts. It was a seven cylinder radial engine with geared propeller. Cylinder bore and stroke was oversquare (bore 5.375", stroke 5.000" or 136.52 x 127.00 mm) and smaller than the R-1830, giving a swept volume of 794.1 in3 or 13.01 litres.

The Cicada was under the design development of Jim Melbourne, working under Engine Superintendent Herb Knight and his assistant Colin Bellward. The engine was de-rated to 450 hp and expected to have an time between overhauls of 1200 hours. It was anticipated that this de-rating would help alleviate overheating problems, which were the result of frequent use of high power and low airspeeds necessary for training manoeuvres and circuit work.

Another feature was the incorporation of gearing for the propeller, unusual for a small engine. The idea was to dramatically reduce the noise from the engine and, more particularly, the propeller tips. Unlike larger engines that used a complex planetary system to reduce propeller speed, the Cicada used a simple ring gear attached to the propeller shaft driven from a pinion gear splined on the front of the crankshaft. Reduction ratio was 10:8. Of course, this set-up meant that the propeller shaft would be offset from the crankshaft, which was designed to be above and thus give slightly increased propeller ground clearance.

The engine featured a full range of accessory drives and a 10:1 ratio on the blower drive gave a rotational speed of 26,000 rpm of the supercharger blower at maximum power. A spring coupling between the crankshaft and blower gearing was provided to minimise shock loads.

Cooling considerations saw generous fins on both the alloy heads and chrome-molybdenum steel barrels of the cylinders. Cooling deflectors were well designed and the engine ran appreciably cooler on tests than did the P&W R-985 Wasp Junior.

With improved cooling and the fact that the engine was able to run at higher rpm due to the reduction gearing, the Cicada of seven cylinders and 795 cubic inches was expected to be able to do the work of the nine-cylinder 985 cubic inch Wasp Junior. One could argue ad infinitum about the relative benefits of less cylinders to wear as against more cylinders operating more slowly, but increased rpm usually does give more power.

R-1830 parts used included the front and rear crankcase forgings, which were held together by high tensile steel bolts. Balance weights were fitted to the cheeks of the crankshaft, which was a two-section shaft with a splined telescopic joint in the centre of a single-throw crank, as per the Wasp engine. Torsional vibration dampers were designed to counteract the torque variation and reduce the effect of vibration and fatigue. They were fitted to each half of the shaft and operated like a pendulum tuned to generate a force equal and opposite to those caused by torque variations. This was considered one of the most critical problems with using seven cylinders of half a twin-row engine, and its successful solution resulted in a smooth running unit.

By mid-1952, the Cicada had completed its first 30 hour test and was being prepared for its full type-trial. On June 9, 1953, Wackett reported on the accidental damage to the Cicada engine installed on a test bed.

In October 1953, the DAP advised CAC that further expenditure on the Cicada would not be authorised as there were sufficient supplies of second-hand reconditioned P&W Wasp Junior engines available from the US, although they conceded that it made sense to complete the development of the Cicada as a research and development project. The CAC Board authorised £4,000 for the completion of the Cicada type testing. All production Winjeels were fitted with the P&W R-985 Wasp Junior engine.

In May 1954, CAC received an inquiry from the Lamson Aircraft Company in Seattle in reference to using the Cicada engine in the export models of Lamson's Air Tractor, a crop duster biplane that first flew in 1953. This aircraft had a gull type upper wing and P&W R-985 engine. Wackett replied favourably but cautioned that it would be 18 months before the production engine would be available. Lamson ceased production in 1955.

From Wirraway to Hornet: History of the Commonwealth Aircraft Corporation Pty Ltd. 1936 to 1985, by Brian Hill. Southern Cross Publications. ISBN 0 646 29314 1