Notes on the Liberty Aircraft Engine [1]

by Paul Dempsey

The United States declared war on Germany on April 6, 1917. At French urging, the Wilson administration promised to produce 6,000 fighters, 3,000 observation planes and 2,000 bombers for the 1918 spring offensive. Congress allocated $640,000,000 to build this flotilla, a sum 45 times larger than the entire 1916 federal budget [1].

The aviation program was a national priority, not unlike the crash program to build Monitor-class warships during the Civil War or, for that matter, the Manhattan Project. Super-weapons have appeal.

The Liberty was central to the effort, since it was intended to provide power for the entire aerial armada. It would also demonstrate the superiority of American mass-production techniques over European handicraft methods [1]. What the Model T had done for automobiles, the Liberty would do for airplanes. By virtue of its numbers and performance, the Liberty would carry American pilots to victory against the Hun.

Mass production called for simplicity and aerial warfare demanded sophistication, in thought as well as hardware. Add to this the pressure under which designers worked, and one can understand the provisional nature of the Liberty, how it came about through a series of expedients.

|

|

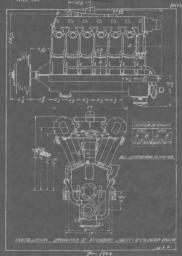

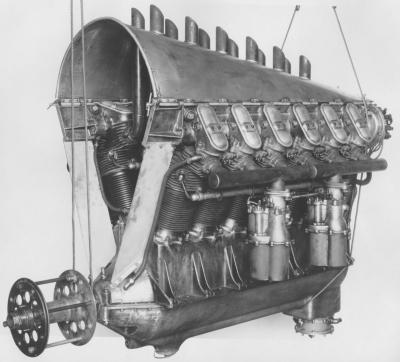

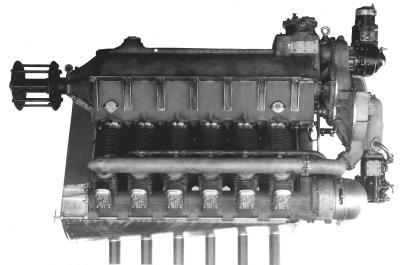

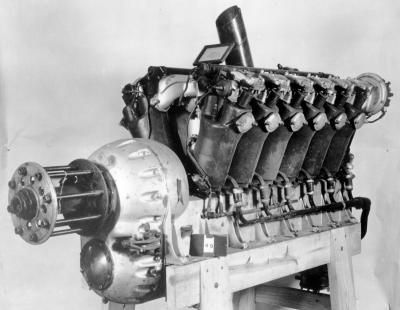

| The Liberty L-12 (Author) | L-12 Installation Drawing (NARA) |

Design

The Aircraft Production Board, then headed up by Howard E. Coffin of the Hudson Motor Car Co. and his assistant Edward A. Deeds, a major stockholder in Delco, set the basic parameters for what would come to be known as the Liberty. The new engine would be lighter and slightly more powerful than the Rolls-Royce Eagle. Modular construction, employing common cylinder and valve components, would slash development time and permit the engine to be used on all types of airplanes from trainers to heavy bombers. And all this would be accomplished within the strictures of a conservative design philosophy.

The first of many expedients was to telescope layout into a two-day (some say five-day) marathon at the New Willard hotel in Washington, DC that begun in the afternoon of May 31, 1917 [3]. J.C. Hall of Hall-Scott provided practical, hands-on input and Jesse C. Vincent, vice-president of engineering for the Packard Motor Co., was charged with the more academic aspects. Design was heavily influenced by a Packard racing engine and by the eight-cylinder Lorraine-Dietrich, then considered as the Allied engine with most potential [4, 5].

Features of the Lorraine-Dietrich incorporated into what was then called the U.S. Standardized Aircraft Engine included a 7” bore and 5” stroke, direct drive to the propeller, and forged steel cylinders with welded-on water jackets as per Lorraine-Dietrich practice. Cylinder construction and the drive arrangement for the single-overhead cam appear to have been borrowed from the Mercedes-Benz D.III [6]. Hispano-Suiza influence was shown in the aluminum crankcase, split horizontally at the main-bearing centerline and tensioned with through-bolts at the bearing bosses. Connecting rods followed automotive practice, Rolls-Royce and Mercedes seem to have provided the pattern for the propeller hub, and so on. Note that these borrowings were neither informed by testing nor by attempts to develop in-house solutions. There was simply no time for that sort of work.

The Aircraft Production Board approved the layout and less than six weeks later Packard had a hand-built 8-cylinder L-8 prototype running on a stand [7]. At General Pershing's request, the L-8 was put on hold in favor of a 12-cylinder L-12 that would be more powerful than existing Allied engines. The first of these was tested in August, 1918.

L-12 specifications:

Vincent and his crew specified off-the-shelf components whenever possible. The most striking example was the Delco ignition system. To my knowledge, only a few post-war Packard aircraft engine used battery-and-coil ignition. But 12-cylinder magnetos did not exist on this side of the Atlantic [7]. Lacking something better also accounts for the obsolete Zenith carburetor.

|

|

| Liberty L-4 (Gary Brossett) | Liberty L-6 (NARA) |

|

|

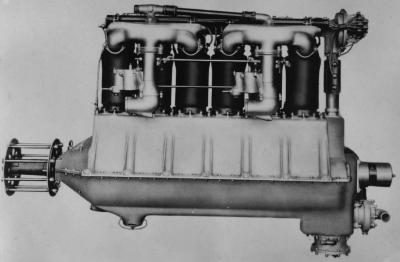

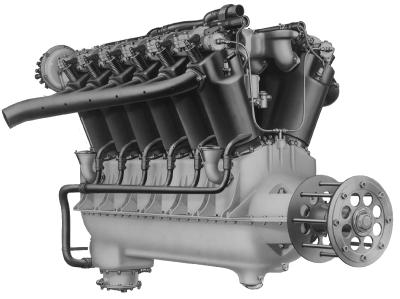

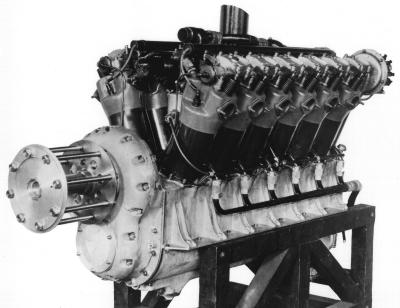

| Liberty L-8 (Gary Brossett) | Liberty L-12 (NARA) |

| Liberty Variants | |

Production

The Aircraft Production Board awarded cost-plus contracts for Liberty production to five automotive concerns: Lincoln (a new operation headed by ex-Cadillac chief Henry Leland), Packard Motor Car, Ford Motor, Nordyke & Marmon, and the Buick and Cadillac divisions of General Motors. The Board was criticized for this, but there appears to have been little choice in the matter. Curtiss would soon be swamped with orders for its own line of engines, Union Switch & Signal had a contract for 2,500 80-hp Le Rhone rotaries, General Vehicle was involved with Gnome engines, and, after extensive redesign work, Wright-Martin was slowly getting the 150-hp Hispano-Suiza into production [9].

Ford Motor, surely the world's best equipped and most experienced high-volume manufacturer, signed on to the program in October, 1917. But Ford managed to turn out only eight engines during the month of May, 1918 [10]. Other firms did no better – total production for February, 1918, amounted to 70 units.

The inertia associated with mass production explains most of the delay. Factories had to be outfitted and, in some cases, built. Lincoln Motor purchased 91,807 special tools in preparation for production [11]. High levels of labor turnover, exotic steels and design changes complicated the work. Between September, 1917 and mid-July 1918, the government ordered 1398 production changes [12]. Partially assembled engines had to be reworked and new tooling fabricated. Finally, as often happens with military contracts, producers simply ignored change orders, apparently at their discretion. How this impacted standardization is unknown.

Things improved near the end of 1918, with 3,878 delivered in October. By war's end, some 13,500 L-12s, 15 L-8s, 52 L-6s and 2 L-4s had been built [13].

Production continued through early 1919 to bring the total to 20,478 L-12s at a unit cost of less than $6,000.

Controversy

Critics of the engine included engineers of stature, such as Henry Crane of Crane Simplex, and self-appointed experts, such as Gutzon Borglum. The later gentlemen, a high honcho in the Ku Klux Klan and friend of President Wilson, would become famous as the sculptor of Mt. Rushmore [14]. In March, 1918, the Department of Justice, headed by Charles Evans Hughes, opened an investigation into the delays in the aviation program. With reference to the L-12, "Quantity production on a large scale was due to begin in December. We were to have three thousand motors in March. In April the motors began to come out at the rate of 15 to 20 a day." [15] The U.S. Senate and the War Department followed up with investigations of their own.

Edward Deeds was removed as chairman of the Aircraft Production Board. Hughes thought the man, who had been given the rank of colonel, should be court marshaled for war profiteering. One source of his profits was the more than 20,000 Delco-supplied ignition systems used on the L-12. Another was his connection with the Dayton-Wright Corporation, an outfit that built DH-4 light bombers with an almost total disregard for quality control. Only one Dayton-Wright plane in six underwent inspection before delivery [16].

Everyone associated with airframes or engines seemed to make vast sums of money. Leland walked off with factory that he used after the war to build Lincoln cars. Packard was $8,000,000 richer for its work on the Liberty. Ford made profits of more than $5,000,000 [17].

Jesse Vincent thought it necessary to write a SAE paper defending his work. He began by addressing the need for a standardized product that could be built in sufficient numbers to affect the war effort. Rather than build 37 different aircraft engines as the English were doing, or 47 like the French, the modular Liberty engine, with four, six, eight or twelve cylinders, would meet all requirements. That was the central point of contention: without a one-size-fits-all engine it would not have been necessary to create the monolithic organization that built it.

Other areas of dispute, such as the use of a bail to secure the oil-pump cover and the performance of Liberty-engined DH-4s, were easy enough to dismiss. Cooling was marginal, at least for the early models.

The 45º cylinder angle raised questions about torsional vibration, which thanks to the excellent work of Robert J. Raymond, now appear to be answered in a definitive fashion [18]. Raymond demonstrates that the L-12 crankshaft underwent severe torque peaks at 1,333 rpm, 1,714 rpm and 2,000 rpm. Any of these inputs could result in failure.

Vincent was certainly aware of torsional vibration and its relationship to brake mean effective pressure. But he assumed that the L-12's uneven firing order, mandated by its crank geometry and bank angle, would alleviate the problem:

“Before we had extensive experience with these engines, it was predicted that we would have a great deal of trouble from breaking due to crankshaft vibration. I know that Rolls-Royce did have serious trouble of this kind, and was forced to put a compensating spring device on the crankshaft gear. I believe that we would have had the same trouble with the Liberty, had the cylinders be placed at an angle of 60 deg. But due to the 45-deg angle, the periodic vibration seems to be broken up to a marked degree.” [19]

Maurice Olley, then at Rolls-Royce and later at Cadillac where he made a science of automotive suspension design, was introduced to the Liberty at the Bureau of Standards in Washington:

“Major Vincent, in uniform, admitted to severe damage to the water pump drive and to the ignition generator. I said he had a torsional vibration. He thought he didn't. I said we had one on the Eagle engine which had a better-looking crankshaft, and one of my last jobs in England had been listening to it with a stethoscope under the belly of the engine, and that we had a damper that would cure it. He was unconvinced." [20]

Initially L-12 cranks parted, sometimes within 50 or 100 hours of initial startup. Vincent ordered the crank cheeks widened, a modification that, he believed, put the matter to rest. Olley agreed, writing that "No Liberty crankshaft broke in France." [21] However Raymond quotes two studies dating from the 1930s that indicate the presence of torsional vibration at certain operating speeds. One of these studies described Liberty crankshaft breakage as "epidemic." [22]

From the very start there were suggestions that the crankshaft may have been coiling and uncoiling like a giant spring. Bevel gears exhibited rapid wear and propeller hubs stuck solid on their tapered connections. A longer key and a slight mismatch between the drive and driven tapers appeared to help. As for the gears, Vincent expressed admiration for the Mercedes system that allowed mating gears to find their own working clearances [23].

The Liberty had other faults. C. Fayette Taylor, who was in a position to know, reported that half of the early production engines could not pass the 50-hr acceptance test. Burnt exhaust valves and, as has been pointed out, accessory-gear failures were common on all versions. [24]

TBO, or time between overhauls, is the primary measure of durability. By 1926 Navy L-12s were averaging 75 hours between overhauls. Newer air-cooled engines had TBOs of 300 hours [25].

Later Developments

When the shooting stopped on the morning of November 11, 1918, only 196 Liberty-powered DH-4s were assigned to active combat units [26]. That was not much of a return on the $640,000,000 investment Congress had made in military aviation.

Once the war ended, the problem became what to do with the engines, for which few airframes were available. Some were donated to the Air Mail Service and vocational schools, and others were sold as surplus for pennies on the dollar. Rum runners found that 400 hp gave them an advantage over Coast Guard cutters. Still, by 1924, 11,810 L-12s remained in inventory, enough to satisfy military needs for 26 years [27].

Although the Liberty had very limited application for military aircraft, the overhang made it difficult to justify acquisition of newer and more expensive power plants.

Attempts to convince commercial operators to adopt the engine on economic grounds failed. It vibrated, weighed more than it should, and had a reputation for unreliability [28]. Army mechanics did their part by foregoing overhauls. When an L-12 needed work, they replaced it with a new one. That practice continued until 1929.

Another approach was to experiment with and upgrade the L-12, an activity that was carried on at McCook Field and by private contractors, most notably Allison Experimental Engineering. Allison modernized some 2,000 L-12s with its proprietary insert-type main and rod bearings. Crumpling babbit had been a perennial problem. The company also manufactured propeller reduction gears, the most successful of which was used on Navy seaplanes. Grover Loening ordered 20 Allison inverted, engines from Allison for his amphibian. This configuration improved pilot visibility and provided additional propeller clearance. It also raised the thrust line.

Allison's most remarkable achievement was the VG-1410, a sleeved-down, inverted and air-cooled L-12, aspirated by means of General Electric centrifugal supercharger. Because of the cost, only a handful were built. Packard was also active in Liberty modification and developed an inverted, water-cooled L-12, known as the 1A-1650. This engine remained in production until 1926.

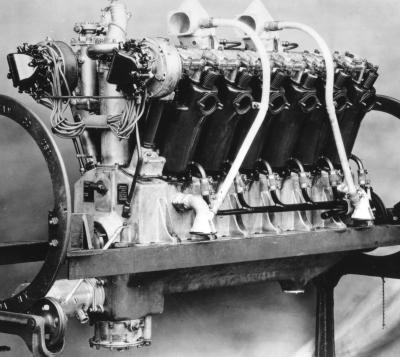

|

|

| Air-Cooled Liberty (NARA) | Inverted Air-Cooled Liberty (NARA) |

|

|

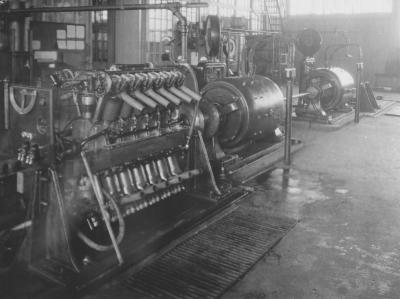

| Inverted Liquid-Cooled Liberty (NARA, shown inverted in stand) | X-24 Liberty on Dynamometer (NARA) |

| Configuration Experiments | |

|

|

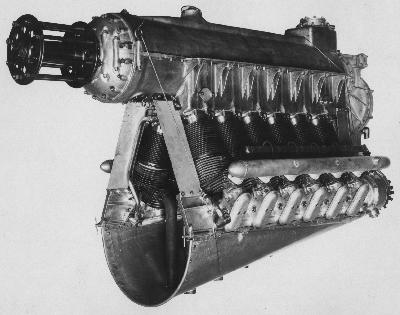

| Allison 2-Speed Geared Liberty (NARA) | Inverted Air-Cooled Liberty with Planetary Gearing (NARA) |

|

|

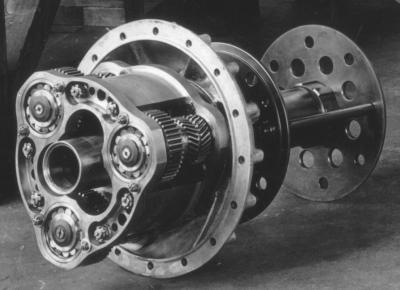

| Planetary Gear Unit (NARA) | Liberty with Spur Gearing (NARA) |

| Gearing Experiments | |

References

[1] Aviation Section, U.S. Signal Corp,http://www.search.com/reference/Aviation_Section,_U.S._Signal_Corps)

[2] Dickey, Philip S.,"The Liberty Engine 1918-1942", Smithsonian Institution Press, Washington, D.C., 1968, p. 8ff.

[3] Vincent, J.G., "The Liberty Aircraft Engines", Society of Automotive Engineers, No. 190020, undated, p. 389.

[4] Snaples, Noble L, "Institutionalizing Aircraft Procurement in the U.S. Navy, 1919-1925, dissertation, Texas A& M University, Aug., 1999 http://www.snaples.com/lsnaples/dissertation/chapter_iii.htm

[5] Vincent, op. cit., p. 390.

[6] Dickey, op. cit., p. 24.

[7] Ibid., p. 17.

[8] Vincent, op. cit., p. 414.

[9] Aviation Section, op. cit.

[10] Venzon, Anne Cipriano, ed., The United States in the First World War: An Encyclopedia, Garland Reference Library of the Humanities, 1995, p. 341.

[11] Leland, Mrs. Wilfred C. and M. D. Millbrook, Master of Precision, Henry M. Leland, Wayne State Univ. Press, Detroit, 1999, ISBN 0-8143-2665-X, p. 184.

[12] Ibid., p. 185.

[13] Dickey, op. cit., p. 18.

[14] Gutzon Borglum, http://en.wikipedia.org/wiki/Gutzon_Borglum.

[15] Leland, op. cit., p. 190.

[16] Snaples, op. cit.

[17] Ibid.

[18] Raymond, Robert J. "The Liberty Engine and Torsional Vibration," AEHS, July 17, 2008.

[19] Vincent, op. cit., p. 410.

[20] William F. and Douglas L. Milliken, eds., Chassis Design: Principles and Analysis, SAE, Warrendale, Pa., 2002, ISBN 0-7680-0826-3, p. 16.

[21] Ibid, pp. 16, 18.

[22] Raymond, opt. cit.

[23] Vincent, op. cit., p. 407.

[24] Taylor, C. Fayette, Aircraft Propulsion: A Review of Aircraft Piston Engines, Smithsonian Institution Press, Washington, D.C., 1971, p. 30.

[25] Wilson, E. E., Commander, "Air-Cooled Engines in Naval Aircraft," SAE Transactions, 1926, Part 2, p. 827.

[26] Venzon, op. cit., p. 315.

[27] Dickey, op. cit., p. 77.

[28] Ibid.