The Atlas Launch System

Compiled by Kimble D. McCutcheon

Unless Noted Otherwise, Photographs by Kimble D. McCutcheon

|

Rocketdyne designed engines for the US Army Jupiter, and US Air Force Thor and Atlas missiles almost simultaneously, and the three engine designs had much in common. We shall discuss the Atlas system, as its engines are representative of all three.

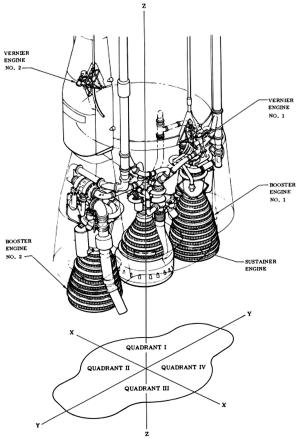

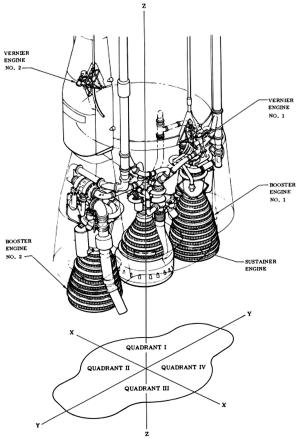

Designed by Convair, the Atlas was the first US Intercontinental Ballistic Missile. Convair realized that much of the risk in multi-stage liquid-fuel rockets involved starting the upper-stage motors in flight, and employed an innovation approach to mitigate this risk, which was the 1-1/2 stage booster concept. Five engines (two boosters, a sustainer, and two verniers) were all started prior to launch. This meant that if an engine failed to start, or failed to generate full power, that all could be shut down and the launch aborted. Once the booster engines had served their purpose, they were jettisoned, along with their tubomachinery and boat-tail aerodynamic fairing. The vehicle continued, sometimes into orbit, on the sustainer engine. The smaller verniers provided roll control, particularly when only the single sustainer engine was running.

Convair's lead structural engineer, Karel Bossart, was keenly interested in lightweight structures. When designing the Atlas, he eliminated the rocket's exterior structure and depended instead on pressurized thin (0.020") welded stainless steel propellant tanks with very little additional structure to bear the huge loads associated with hypersonic flight (video).

Many rocket engineers were skeptical of this approach, but his theories were exonerated when the first Atlas was launched on 11 June 1957, and suffered an engine failure that caused it to tumble end-over-end until it was destroyed by the Range Safety Officer (video).

The US detonated its first thermonuclear device in 1 November 1952, and atmospheric fallout residues sampled by the US in 1953 indicated that the Soviet Union was not far behind. Atlas quickly went from interesting concept to the highest priority Department of Defense project. Thermonuclear weapons in those days were extremely heavy, which required new propulsion concepts.

|

| Friendship 7 Launch (NASA) |

|

|

|

|

| The 1-1/2 Stage USSRC NASA Atlas. The boat tail and outboard booster engines are jettisoned after the initial boost phase, leaving the sustainer and verniers to run for the remainder of the boost. |

USSRC NASA Atlas |

USSRC NASA Atlas |

USSRC NASA Atlas |

Rocketdyne introduced five key innovations when developing the Navaho Phase II and III propulsion systems, which led to Atlas/Jupiter/Thor propulsion.

- RP-1 and LOX were chosen as the fuel and oxidizer.

- Gas generators replaced the steam generators for turbopump power.

- Thrust chambers were formed from thin-walled tubes brazed together.

- Bell-shaped nozzles replaced the conical ones of the V-2 and Redstone.

- Rocket directional control was achieved through the use of gimbaled engines.

RP-1 Fuel - When burned, ethanol produces 11,600 BTU/lb, while JP-4 jet fuel produces about 18,500 BTU/lb. In its direction of the Navaho program, the US Air Force insisted that it be fueled by JP-4, which was intended to give it more power per pound. Rocketdyne objected, because JP-4 production and purity standards were too loose to permit its use as a rocket fuel. Finally, a highly-refined version of JP-4 known as RP-1 (Rocket Propellant 1) was developed. LOX was retained as the oxidizer. This combination became the basis for a number of rocket engines.

Gas Generators - Steam-driven turbopumps, which had been used on the V-2 and Redstone, in addition to having power limitations, were heavy and complicated. Navaho Phase II introduced turbopump gas generators fueled by the same propellants used in the rocket engine combustion chambers. The new MK-3 turbopump turbine drove high-pressure fuel and oxidizer pumps through a high-speed gear train, which reduced the turbine size and weight while increasing its efficiency. The new turbopump design suffered some development failures as lubrication and part-clearance problems were sorted out, but ultimately became a reliable system.

Thrust Chambers - Double-walled regeneratively-cooled thrust chambers, such as those used in the V-2 and Redstone, had been pioneered in the 1930s by James H. Wyld of the American Rocket Society, and later, Reaction Motors/Thiokol. Unfortunately, these formed and welded sheet metal thrust chambers were difficult and expensive to fabricate. Edward A. Neu, Jr. invented another approach that used pre-formed tubes that were brazed together to form thrust chambers. Fuel flowed from the injector through some of these tubes to a manifold at the nozzle exit, where it reversed direction and flowed back to the injector, where it was injected and burned. Circumferential bands strengthened the assembly, and this construction was adopted for nearly all liquid fuel rocket engines (see US Patent 3190070).

Bell-Shaped Nozzles - Conical nozzles used on the V-2 and Redstone did not produce an ideal axial exit gas flow pattern. By the mid 1950s, computers had become available that allowed Rocketdyne's G.V.R. Rao to calculate ideal nozzle shapes and dimensions, which form the now-familiar bell shape.

Directional Control - Both the V-2 and Redstone had used a combination of aerodynamic fins with moveable tabs and carbon vanes in the exhaust stream to guide the missile. This approach had significant disadvantages, including the aerodynamic drag of the fins and vanes, along with reliability issues with the carbon vanes. Rocketdyne achieved the same result by hinging (later gimbaled) engines, which used the thrust vector to control the rocket.

|

|

|

|

| Atlas Internals (Rocketdyne) |

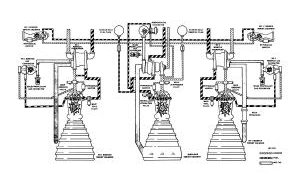

Atlas Engine Schematic (Rocketdyne) |

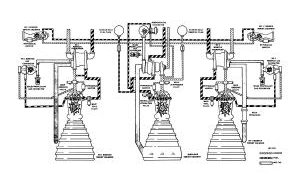

Early Atlas Booster and Sustainer Engine Configuration. Boosters shared a turbopump gas generator. (Rocketdyne) |

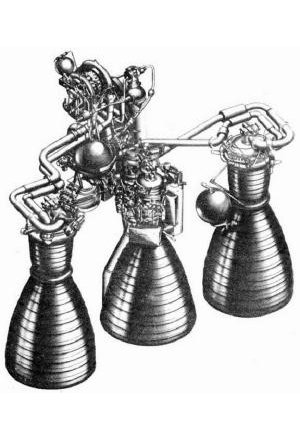

Later Configurations Used Identical Booster Engines wiht Separate Gas Generators (Rocketdyne) |

|

|

|

|

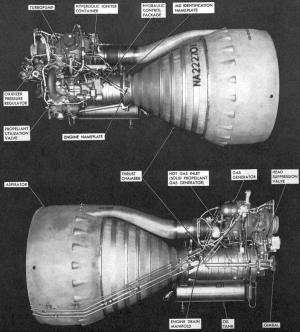

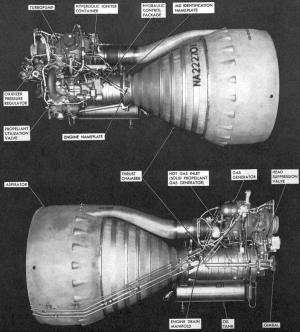

| LR-105 Sustainer Engine. Note that the turbopump turbine exhausts into an aerator around the nozzle, improving efficiency. (Rocketdyne) |

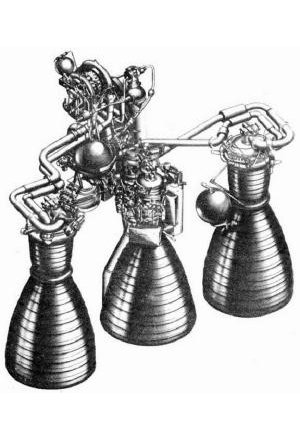

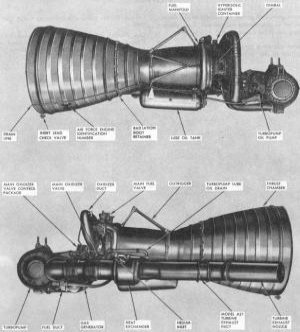

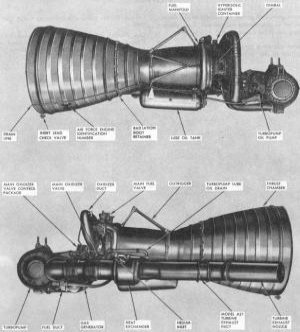

Later Generation LR-89 Booster Engines (Rocketdyne) |

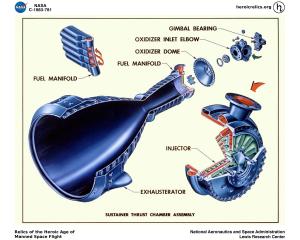

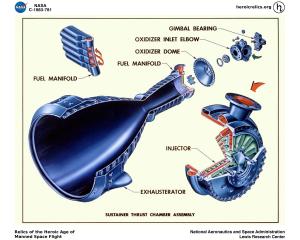

LR-105 Sustainer Engine Details

(heriocrelics.org) |

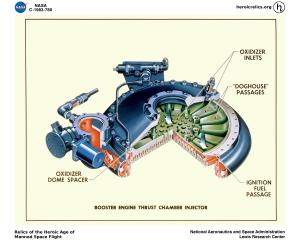

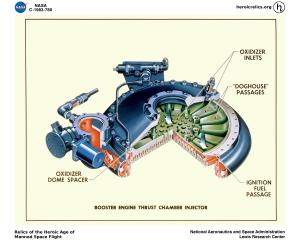

LR-89 Injector Details

(heriocrelics.org) |

LR-89 Booster Engines

Two LR-89 engines provided booster thrust for the Atlas launch system, and were jettisoned once the booster role was complete. In early missiles, both engines were fed by remote turbopumps that were powered by a single gas generator. Later versions had a gas generator for each engine, which were identical. Project Mercury-Atlas reverted to the single gas generator because it was thought to be more reliable. The LR-89 burned LOX and RP-1 to produced nearly 150,000 lbT at sea level and 171,000 lbT in a vacuum. It had a chamber pressure of 580 psia, a sea level specific impulse of 248 sec, a vacuum specific impulse of 282 sec, and a burn time of 135 sec. Thrust to weight ratio was 120.3.

LR-105 Sustainer Engine

The sustainer engine continued to provide thrust after the booster engines had been jettisoned. Its turbopump also fed the vernier engines. The LR-105 burned LOX and RP-1 to produced 60,473 lbT at sea level and 86,866 lbT in a vacuum. It had a chamber pressure of 700 psia, a sea level specific impulse of 220 sec, a vacuum specific impulse of 316 sec, and a burn time of 368 sec. Thrust to weight ratio was 85.6.

LR-101 Vernier Engine

The two vernier engines were fed propellants from the sustainer engine turbopump and each produced about 1,000 lbT for as long as the sustainer engine operated.

The Atlas Legacy

The Atlas launched satellites, space probes and four US astronauts (John Glenn, Scott Carpenter, Wally Shirra and Gordon Cooper). It remained in production for 47 years and set a record of 77 consecutive successful launches.