Bristol Hydra

by Brian Perkins

The Hydra is a 16-cylinder, twin row, twin overhead camshaft, poppet valve unit with the two rows of cylinders in line to allow for the camshafts. There are only two valves per cylinder, which are operated by the overhead cams through bucket tappets. The whole design of the engine is so completely different to anything else that Sir Roy Fedden had been concerned with that I cannot help feeling that the designer, Frank Owner, was given a much freer hand than normal, probably due to the concentration by Fedden on the sleeve valve concept. An immediate question asked by anyone who knows about radial engines is, "why an even number of cylinders per row?" The generally accepted reason is that the prototype test engine was built as a V4 and when this showed promise they just multiplied by four. Only two Hydras were ever built and one of these was test flown in the Hawker Harrier, which Bristol used for a variety of test engines. It apparently suffered from severe vibration at critical speeds and although I am sure that this could have been cured by an intensive development programme, the engine was dropped in favour of the new sleeve valve engines, which had started to work well enough to be put into production. |

Hydra Displays

|

|

|

|

|

|

|

|

| Original Hydra | Trial Assembly | Trial Assembly | Trial Assembly | Crankcase, Crankshaft | Crankshaft Installed | Cylinder Heads | Cam Boxes |

Crankcase

"The blank originally weighed 22 lb and ended up weighing only 1.65 lb. For a one-off it is still the best way."

|

|

|

|

|

|

|

| Mini-Prototype | Blank | |||||

|

|

|

|

|

|

|

| Finished Crankcase | Finished Crankcase | Finished Crankcase |

Crankshaft

|

|

|

|

|

|

|

|

Cylinder Heads

|

|

|

|

|

|

|

|

|

|

| Blanks | Blanks | ||||||||

|

|

|

|

|

|

|

|

|

T.jpg) |

T.jpg) |

T.jpg) |

T.jpg) |

T.jpg) |

|

|

|

|

||

| Complete Cylinder | Complete Cylinder | Machining Fixture | Machining Fixture |

Cam Boxes

Sitting on top of the cylinder heads are the 32 cam boxes which again caused a considerable amount of head scratching as to the best way of producing them. I could see no way to machine them from the solid, tried producing a rubber mould for casting but eventually decided that to achieve the finning and other features the best way was to fabricate them. It was a lot of work but produced a pleasing end result. These 32 cam boxes had to be made into 16 front (easy), 4 rear RH with gearbox, 4 rear LH with gearbox, 4 rear RH with gearbox and drive and 4 rear LH with gearbox and drive.

|

|

|

|

|

|

|

|

|

| Fin Bending Jigs | Fin Bending Jigs | |||||||

|

|

|

|

|

|

|

|

Cam, Accessory, Magneto and Supercharger Drive Gears

|

|

|

|

|

|

|

|

|

Magneto Drive

|

|

|

|

Rear Crankcase Cover

|

|

|

|

|

Supercharger Diffuser and Rear Cover

|

|

|

|

|

|

|

|

|

|

Speed Reducer Cover

Fins on the speed reducer housing were machined with the aid of two rotary tables.

|

|

|

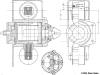

Drawings

|

|

|

|

|

|

|

|

| Longitudinal GA | Tranverse GA | Crankshaft | Connecting Rods | Gears | Firing Order | Magneto | Cam Profile |